Installation

28 300324726_002_C0 - 10/2016 - © Leybold

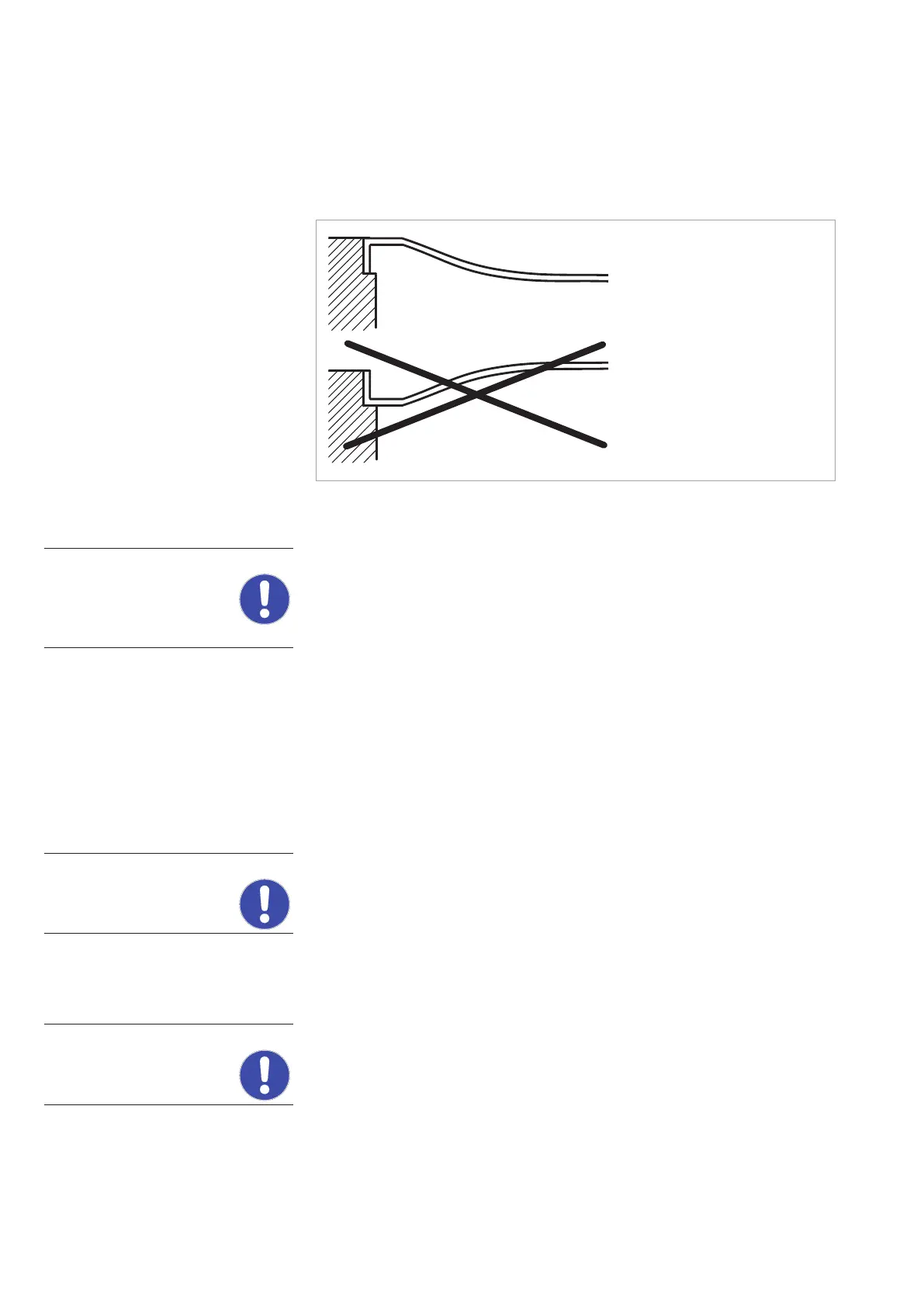

Install an inlet screen

Foreign objects which enter the pump through the intake would cause seri-

ous damage to the rotor. That’s why we recommend installing an inlet

screen. Damages caused during operation without the inlet screen are

excluded from warranty.

Insert the inlet screen so that the surface curvature is at the bottom and

apply some pressure lightly at the rim so that the inlet screen engages, see

Fig. 3.3.

If dust could pass from the vacuum chamber into the pump, then a micro-

pore filter must be installed between the vacuum chamber and the pump.

Flange mounting for ISO-F flanges

Mount the turbomolecular pump according to Fig 3.4 and tighten the bolts

crosswise step-by-step.

The contact surfaces of pump housing, vacuum system and centering ring

must be free of grease and dry so as to ensure adequate strength in case

the rotor should seize.

Flange mounting for CF flanges

Before fitting, check to ensure that the sealing edge is undamaged. Do not

touch the copper gasket and the sealing edge with your bare hands.

The contact surfaces of pump housing, vacuum system and centering ring

must be free of grease and dry so as to ensure adequate strength in case

the rotor should seize.

Mount the turbomolecular pump according to Fig 3.5 and tighten the bolts

crosswise step-by-step.

When the pump shall be baked out, the threads of the bolts should have

been lubricated with a high temperature lubricant.

NOTICE

NOTICE

NOTICE

Fig. 3.3 Installing the inlet screen

Correct

Wrong

NOTICE

Install the inlet screen as shown.

Installing the inlet screen upside

down may lead to contact bet-

ween inlet screen and rotor duri-

ng fast venting of the pump.

Loading...

Loading...