5-5

Copyright © LG Electronics Inc. All rights reserved.

Only training and service purposes

CONVERSION TO LP GAS

If the flame is lifting

off of the burner

ports, gradually

reduce the air shutter

opening until flames

have stabilized.

Some yellow tipping

may be normal when

used on LP.

Approx. 1”

INNER CONE

OF FLAME

OVEN

BURNER

9. LEAK TESTING AND CHECK GAS PRESSURE

1) Check all gas connection joints and fittings for

leaks with a non-corrosive leak detection fluid,

then wipe off.

2) Check and properly adjust the gas pressure.

CAUTION

The range is designed to operate at

a pressure of 5” of water column on

natural gas or 10” of water column

on LP. For proper operation, the

pressure of natural gas supplied to

the regulator must be between 6”

and 10.5” of water column. For LP

gas, the pressure supplied to the

regulator must be between 11” and

13” of water column.

10. CHECK FLAME QUALITY

The combustion quality of the burner flames

needs to be determined visually.

A. Yellow Flames:

Further Adjustment Required

B. Yellow tips on outer cones:

Normal for LP Gas

C. Soft Blue flames:

Normal for Natural Gas.

NOTE: If burner flames look like A, further air

shutter adjustment is required. B or C is normal

for burner flames, depending on the type of gas

you use. With LP gas, some yellow tipping on the

outer cones is normal.

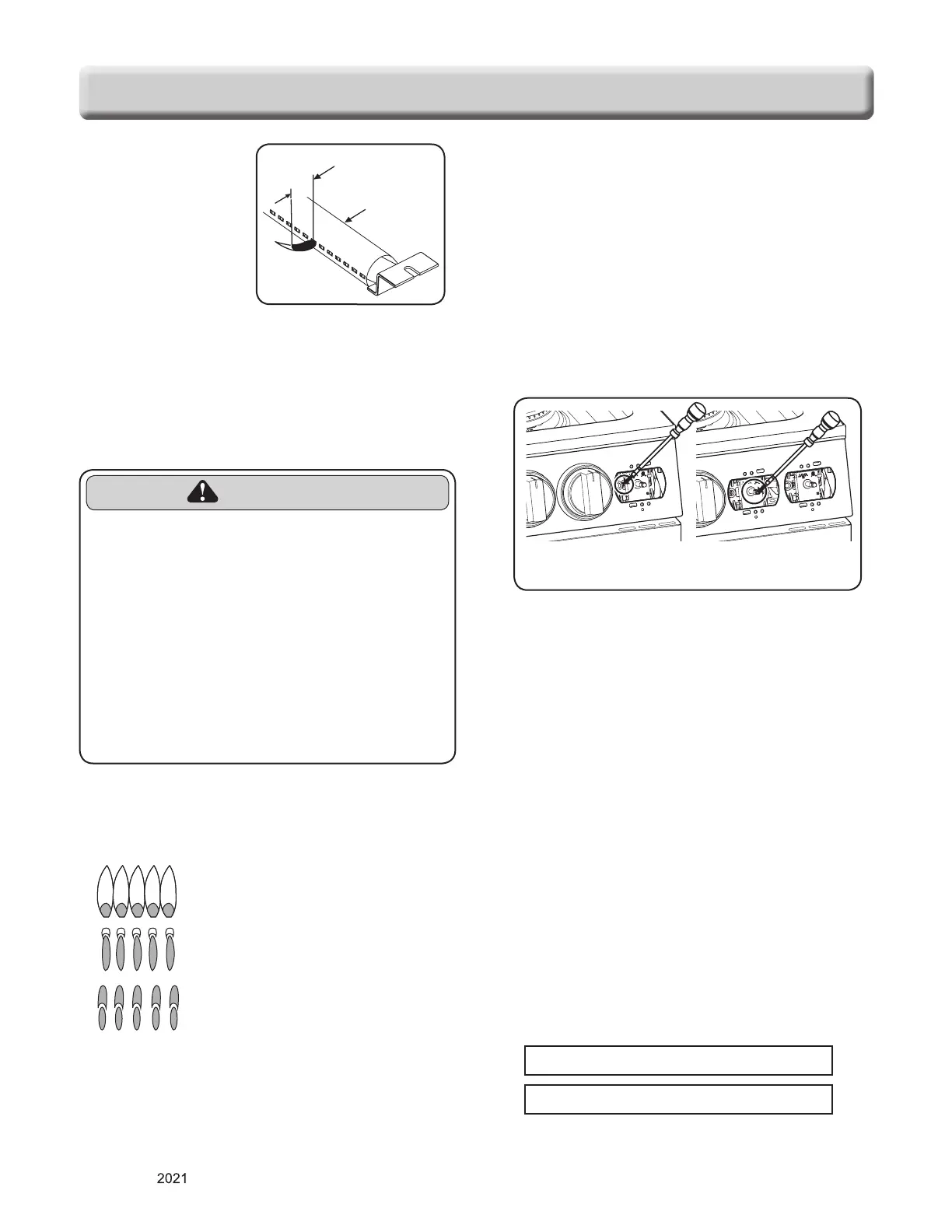

11. ADJUST SURFACE BURNER LOW FLAME

(SIMMER) SETTING

1) Light all surface burners.

2)

Turn the knob on the burner being adjusted to LO.

3) Remove knob and knob ring.

4) Insert a small, flat bladed screwdriver into the

valve shaft as shown in Fig.1.

Turn the adjustment screw until the flame

reaches the desired size.

5) Replace the knob.

Note: Hold the valve shaft with one hand while

turning the screw for adjustment with the other.

Dual burner simmer burner simmer excluding

Dual burner

Fig.1

6) Test The Flame Stability.

Test 1:

Turn the knob from HI to LO quickly. If

the flame goes out, increase the flame size and

test again.

Test 2:

With the burner on a LO setting, open

and close the oven door quickly. If the flame is

extinguished by the air currents created by the

door movement, increase the flame height and

test again.

7) Repeat steps 1-5 for each surface burner.

12. CONVERSION STICKER

Upon completion of the conversion, fill out the

LP sticker located with the instructions. Once

complete, attach the sticker to the back of the

range near the regulator.

Place all orifices that were removed for natural gas

back into the plastic bag along with the instructions.

Place the kit back into its original location.

If converting back to natural gas from LP remove

the LP sticker from the back of the range.

CONVERSION IS FINISHED

To convert to the original gas.

Follow conversion process with original orifices to

convert the appliance to the original gas.

Loading...

Loading...