136 137

_TROUBLE SHOOTING GUIDE BOOK _

- 152 -

Copyright ©2017 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1. Wrong operation of 4way valve because of sludge

etc. inflow

2. No pressure difference because of compressor

fault

3. Wrong installation of In/outdoor common pipe

4. Defect of 4way valve

Error

No.

Error Type Error Point Main Reasons

Function error of 4way

(reversing valve) in Main or

Slave outdoor units

Function error of outdoor

4way (reversing valve)

151*

Master

1511

n Error diagnosis and countermeasure flow chart

Is 4-Way valve connecter

connection are properly

connected?

No

Reconnect it

After reset, can we

check supply voltage at PCB

when starting heating

mode operation****

No

Is 4 way valve coil connected

to 4 way valve normally?**

ø

No

Is 4 Way valve coil

resistance normal?*

Change 4 Way valve coil

No

Yes

In case of more than

2 units, does master outdoor

unit recognize as more

than 2 units? ***

Refer to CH 51 & make measure

Yes

Is compressor working

normally?

No

Check and replace compressor,

Magnet switch, corresponding PCB

[refer electric component part]

Yes

Re-insert 4 way valve coil

Replace outdoor unit PCB

Yes

Yes

No

Replace 4 way valve*****

After opposite

mode operation to present

mode, is the same error

occurred again?

If the same error is occurred in

near future replace 4way valve

Yes

Yes

No

Error No. Error Type Error Point Main Reasons

151*

Function error

of outdoor 4way

(reversing valve)

Function error of

4way (reversing

valve) in Main or

Slave outdoor units

1. Wrong operation of 4way valve because of

sludge etc. inflow

2. No pressure difference because of com

-

pressor fault

3. Wrong installation of In/outdoor common

pipe

4. Defect of 4way valve

▒

Error Diagnosis and Countermeasure Flow Chart

- 151 -

Copyright ©2017 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Check liquid bypass

1. Individual power of indoor unit is

open during operation

2. Indoor unit EEV fault(ref. leak

much)

3. Indoor unit EEV connector discon-

nected.

4. SC EEV fault(ref. leak much)

5. Liquid pipe – gas pipe direct con-

nection

Error No. Error Type Error Point Main Reasons

Discharge

superrheat is

under 3℃

(liquid back)

Discharge superheat low

CH150

Is EEV head(Coil)

assembly normally?

Change EEV assembly

Yes

Yes

Yes

No

Yes

No

No

No

Is EEV connector

connected normally?

Is there indoor unit

which leaks ref.

much

1)

?

Is SC EEV or SC

circuit leaks?

Change SC EEV or SC EEV

assembly

Assemble again or change

EEV head(coiL)

Connect EEV connector

Check liquid pipe

– gas pipe direct connection

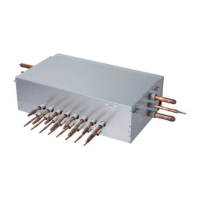

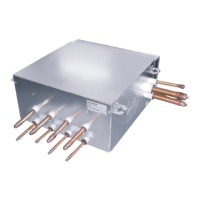

* Measuring input voltage

* Noise filter wiring

R(L1) S(L2) T(L3) N

1) Ref. leakage much

: Both Pipe in, pipe out temp. is under 10℃

during unit is off(EEV 40pls)

Also, big refrigerant flow noise occured

n Error diagnosis and countermeasure flow chart

Error No. Error Type Error Point Main Reasons

150*

Discharge

superheat low

Discharge super

-

rheat is under 3℃

(liquid back)

Check liquid bypass

1. Individual power of indoor unit is open

during operation

2. Indoor unit EEV fault(ref. leak much)

3. Indoor unit EEV connector disconnected.

4. SC EEV fault(ref. leak much)

5. Liquid pipe - gas pipe direct connection

▒

Error Diagnosis and Countermeasure Flow Chart

Basic PartBasic PartBasic PartBasic Part

Loading...

Loading...