140 141

_TROUBLE SHOOTING GUIDE BOOK _

- 156 -

Copyright ©2017 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

n Error diagnosis and countermeasure flow chart

Is temperature sensor

connector connections

are normal?

Is the value of temperature

sensor resistance normal?*

Check and correct connection

Replace sensor

Replace outdoor unit PCB

Yes

Yes

No

No

* Measuring input voltage

* Noise filter wiring

R(L1) S(L2) T(L3) N

* Sensor resistance 100 kΩ over (open) or 100 Ω below (short) will generate error

Note: Temperate sensor resistance vary with temperature, So compare temperature sensor resistance value

according to outdoor unit temperature by referring below table (±5% tolerance)

Air temperature sensor: 10°C = 20.7kΩ : 25°C = 10kΩ : 50°C= 3.4kΩ

Pipe temperature sensor: 10°C = 10kΩ : 25°C = 5kΩ : 50°C= 1.8kΩ

Error No. Error Type Error Point Main Reasons

194*

Master

1941

Slave1

1942

Slave2

1943

Slave3

1944

Outdoor unit Fan PCB

heatsink temperature

sensor error

Outdoor unit Fan PCB

heatsink temperature

sensor error

1. Defective temperature sensor connection

2. Defective temperature sensor (Open / Short)

3. Defective outdoor unit PCB

Error No. Error Type Error Point Main Reasons

194*

Outdoor unit Fan

PCB heatsink

temperature sensor

error

Outdoor unit Fan

PCB heatsink

temperature sensor

error

1. Defective temperature sensor connection

2. Defective temperature sensor(Open / Short)

3. Defective outdoor unit PCB

▒

Error Diagnosis and Countermeasure Flow Chart

- 155 -

Copyright ©2017 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

n Error diagnosis and countermeasure flow chart

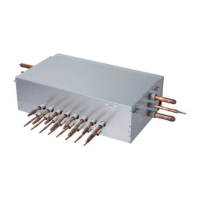

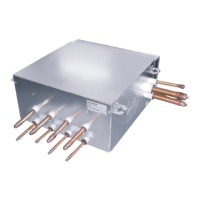

n Check Fan PCB Screw Connection Condition

Error No. Error Type Error Point Main Reasons

193*

Master

1931

Slave1

1932

Slave2

1933

Slave3

1934

Fan PCB Heatsink

Temperature High

Heatsink Temperature

is Over 90°C

1. Fan PCBA IPM Connection Condition Abnormal

2. Outdoor Unit Fan Motor Operation Abnormal

3. Outdoor Unit Fan PCB Assembly Defect

4. Overload Operation (Pipe Clogging/ Covering/EEV

Defect/Ref. Overcharge)

Is Installation

Condition Normal?

No

1. Check Pipe Clogging/ Distortion

2. Check Covering (Outdoor/Indoor Unit)

3. Check EEV Connector Assemble Condition/Normal Operation

4. Check Refrigerant Pressure

5. Check Power Wire/ Connection Condition

Reassemble or Manage if abnormality Found

1. Check Fan PCBA Screw Connection Condition

Reassemble or Manage if abnormality Found

No

Fan PCB IPM Connection

Condition Normal?

Yes

1. Check Outdoor Unit Fan Motor Operation or Lock

Reassemble or Manage if abnormality Found

No

Is ODU Fan Motor Normal?

Yes

1. Reset

Replace Fan PCB Assembly

No

Is Fan PCB assembly

Normal?

Yes

Recheck Power and

Installation Condition

Yes

Check Screw Connection Condition

Error No. Error Type Error Point Main Reasons

193*

Fan PCB Heatsink

Temperature High

Heatsink Tempera

-

ture is Over 90℃

1. Fan PCBA IPM Connection Condition Ab

-

normal

2. Outdoor Unit Fan Motor Operation Abnormal

3. Outdoor Unit Fan PCB Assembly Defect

4. Overload Operation (Pipe Clogging/ Cover

-

ing/EEV Defect/Ref. Overcharge)

▒

Error Diagnosis and Countermeasure Flow Chart

Basic PartBasic PartBasic PartBasic Part

Loading...

Loading...