162 163

_TROUBLE SHOOTING GUIDE BOOK _

3.3 Precautions of Replacement

1. EEV should be judged correctly and replaced

2. Replaced EEV should be returned for cause analysis

3. Do not transfer heat to EEV body when welding

4. In case use the refrigerant after welding, be careful welding crack and the body damage

5. Be careful not to damage terminals when PCB is fastened

(Contact failure prevent )

6. PCB reset after replacement and check operation sound is normal

7. Vacuum at least 4 ~ 5 hours after welding.

8. After vacuum processing, please charge the refrigerant by calculating the additional amount of refrigerant

according refrigerant basic amount of the enclosed, outdoor unit charging factor, the pipe length.

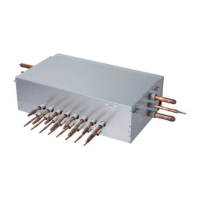

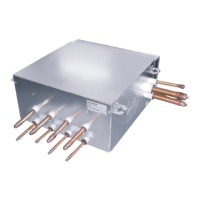

4.1 Variable Path Valve

4. Solenoid Valve

1. Basic control

- Base : Off

- Cooling mode : Open

- Low temperature cooling mode : Close

- Heating mode : Close

2. Failure Phenomenon

1) Open Failure

: The upper EEV is closed and the refrigerant flow is blocked. So, the high pressure rises sharply

→ CH34, High-pressure switch ON, Main PCB Off

2) Close Failure

: The refrigerant passing through the upper EEV does not go to the heat exchanger but enters

accumulator through the variable path valve

→ Heat capacity decrease, Excessive temperature difference between upper / lower heat exchanger

(more than 15 degrees)

Check that the output signal of the control board matches the operation of the solenoid valve.

3. 솔레노이드 밸브

1. 가변 패스 밸브 상태

상시 : Off 상태

제어 : 일반 냉방 운전 시 Open, 냉방 저온 운전 시 Close, 난방 운전 시 Close

2. 불량 현상

1) 밸브 Open 불량

상부 EEV가 Close되어 냉매 흐름이 막히고 고압이 급격히 상승함

→ CH34 발생, 고압 스위치 작동 및 Main PCB Off 됨

2) 밸브 Close 불량

상부 EEV를 통과한 냉매가 열교환기로 가지 않고, 가변 패스 밸브를 통해 Accum으로 들어감

→ 난방 운전 시 능력 저하, 열교환기 온도와 상/하부 열교환기 온도차 과다 발생 (15 ℃ 이상)

Basic PartBasic PartBasic PartBasic Part

Loading...

Loading...