21

2 - INSTALLATION AND START-UP

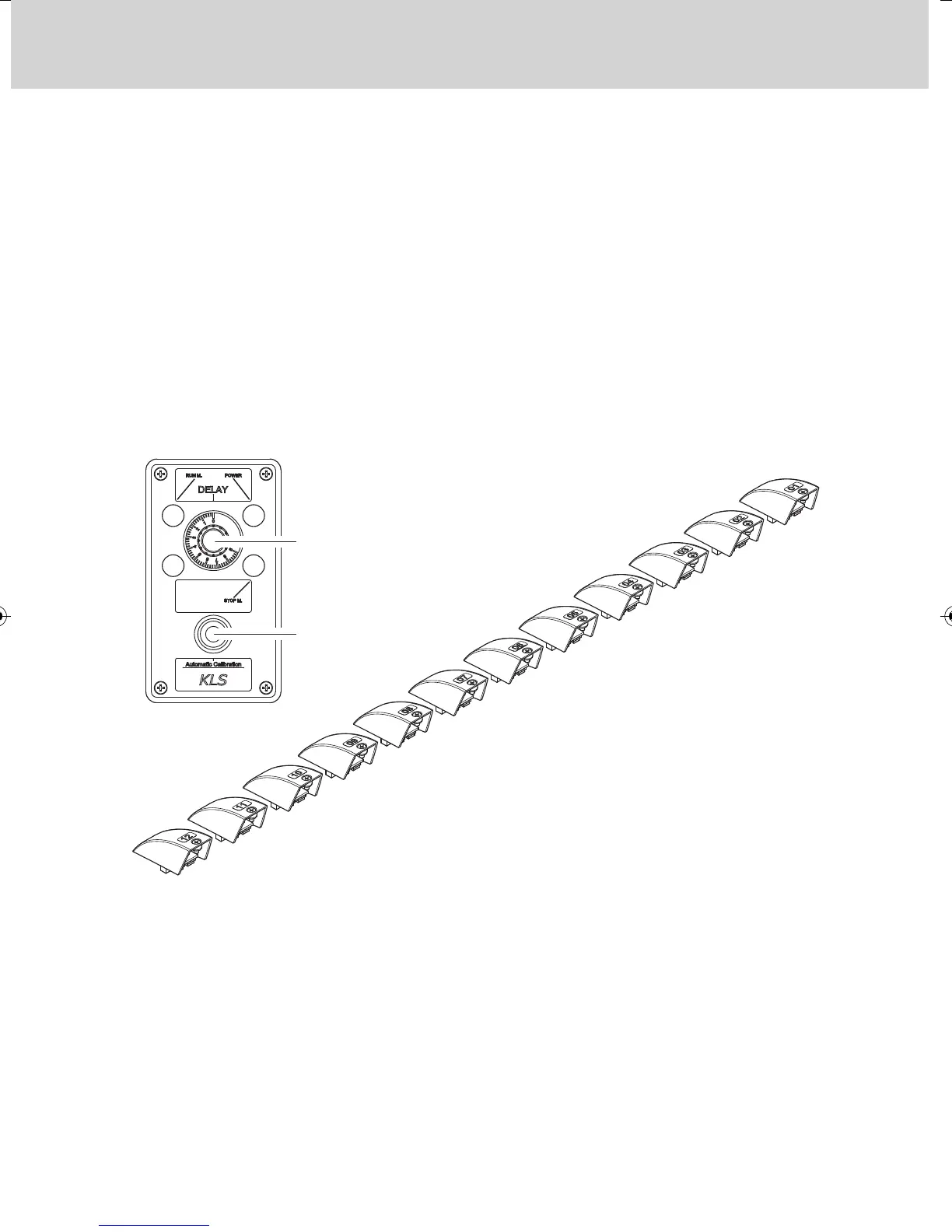

2.4 DETECTION OF YARN BREAKAGE ON FEEDER OUTLET: KLS KIT

This kit allows any irregular use of yarn by the machine to be detected

without using any mechanical sensors.

These sensors bring about undesired changes in yarn tension that are

likely to negatively affect the overall efficiency of the equipment.

The KLS KIT allows these sensors to be completely removed with no need

to replace them, as it only makes use of the sensors already found in the

feeder.

This Kit, unlike mechanical sensors, does not simply detects breakages,

but also other events, e.g. cases when the yarn, though in tension, moves

out of the needles and is not properly fed any longer.

Potentiometer: time set by the machine to reach the working speed from the

idle state. Set this value to 3 seconds.

Automatic learning push-button: each feeder learns the characteristic speed

of the item being processed.

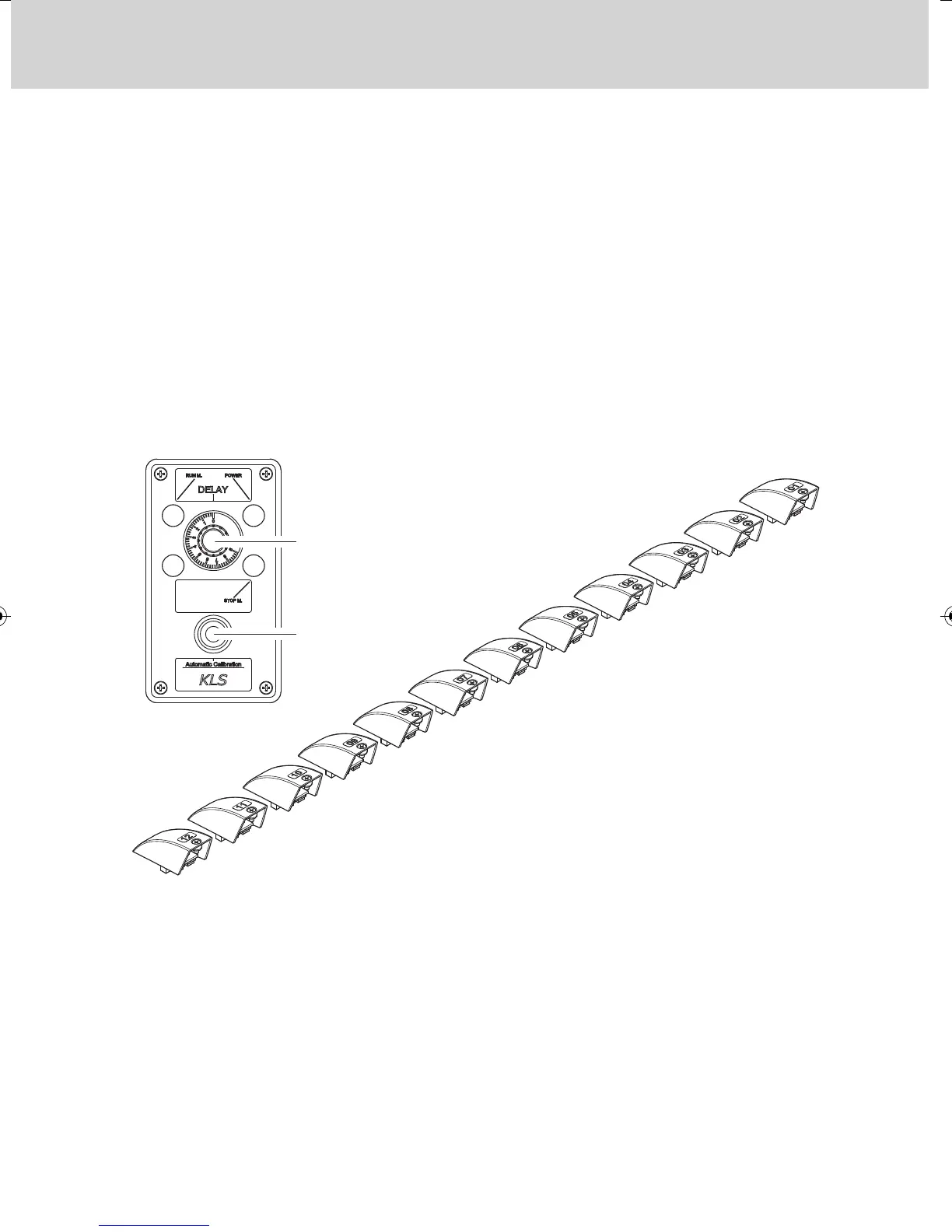

Procedure (to be carried out at every item change):

1. Press the PUSH-BUTTON. The feeders’ lights will switch off.

2. Start the machine, produce a complete item then stop the machine.

During production, the outlet detection system does not operate.

3. When the machine stops, the feeders will store the speed value.

4. Upon restarting the machine, the system will be active and operating.

potentiometer

automatic

learning

push-button

Loading...

Loading...