8

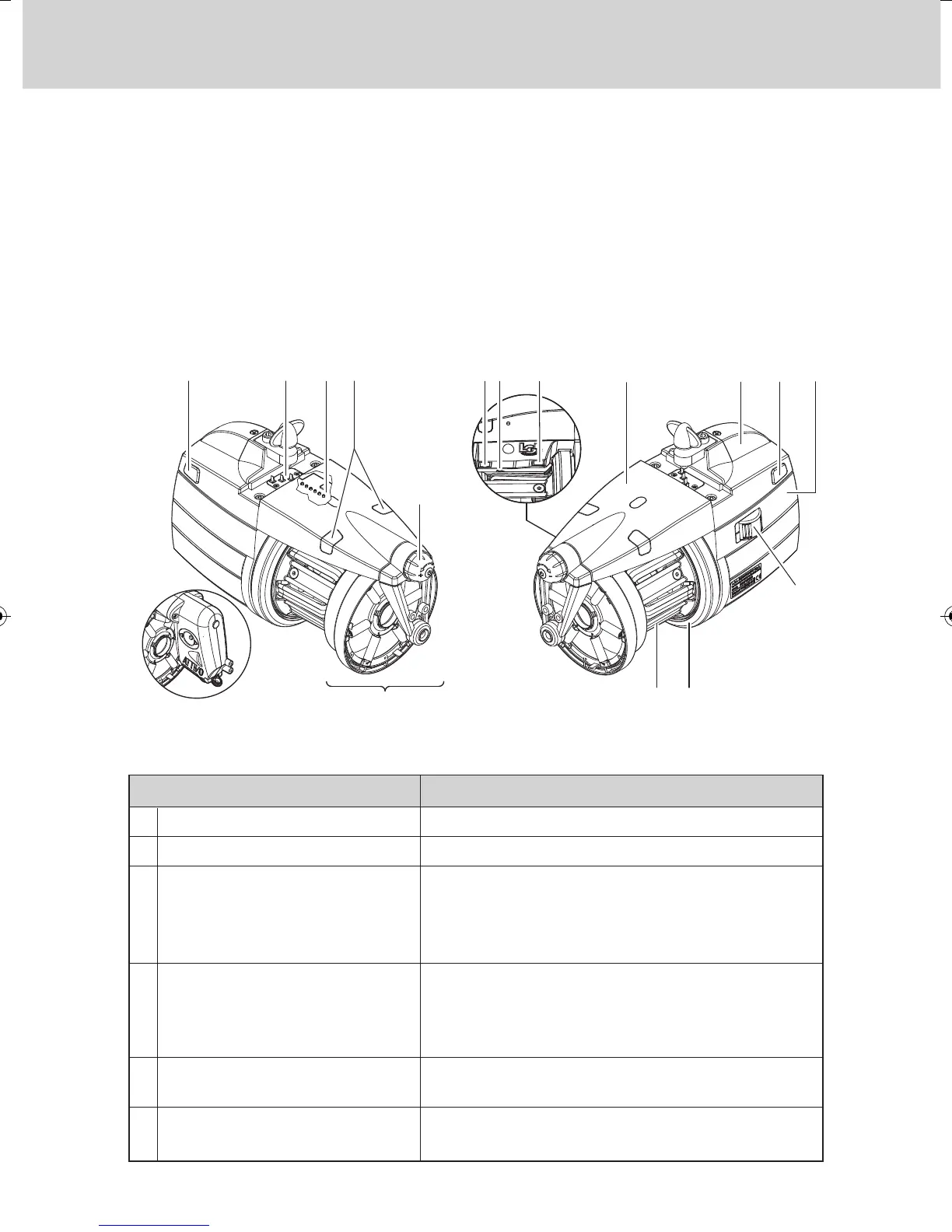

1.1 MAIN PARTS – CONTROL AND ADJUSTMENT POINTS

Main Parts:

1 • MOTOR 6 • OPTICAL OUTPUT SENSOR

2 • TOP PANEL 7 • POWER CABLE CONNECTION

3 • FLYWHEEL 8 • MAIN ELECTRONIC CONTROL BOARD

4 • YARN SPOOL BODY 9 • WINDING RESERVE CONTROL FEELER

5 • OUTPUT TENSIONER UNIT 10 • INPUT FEELER

1 - GENERAL FEATURES

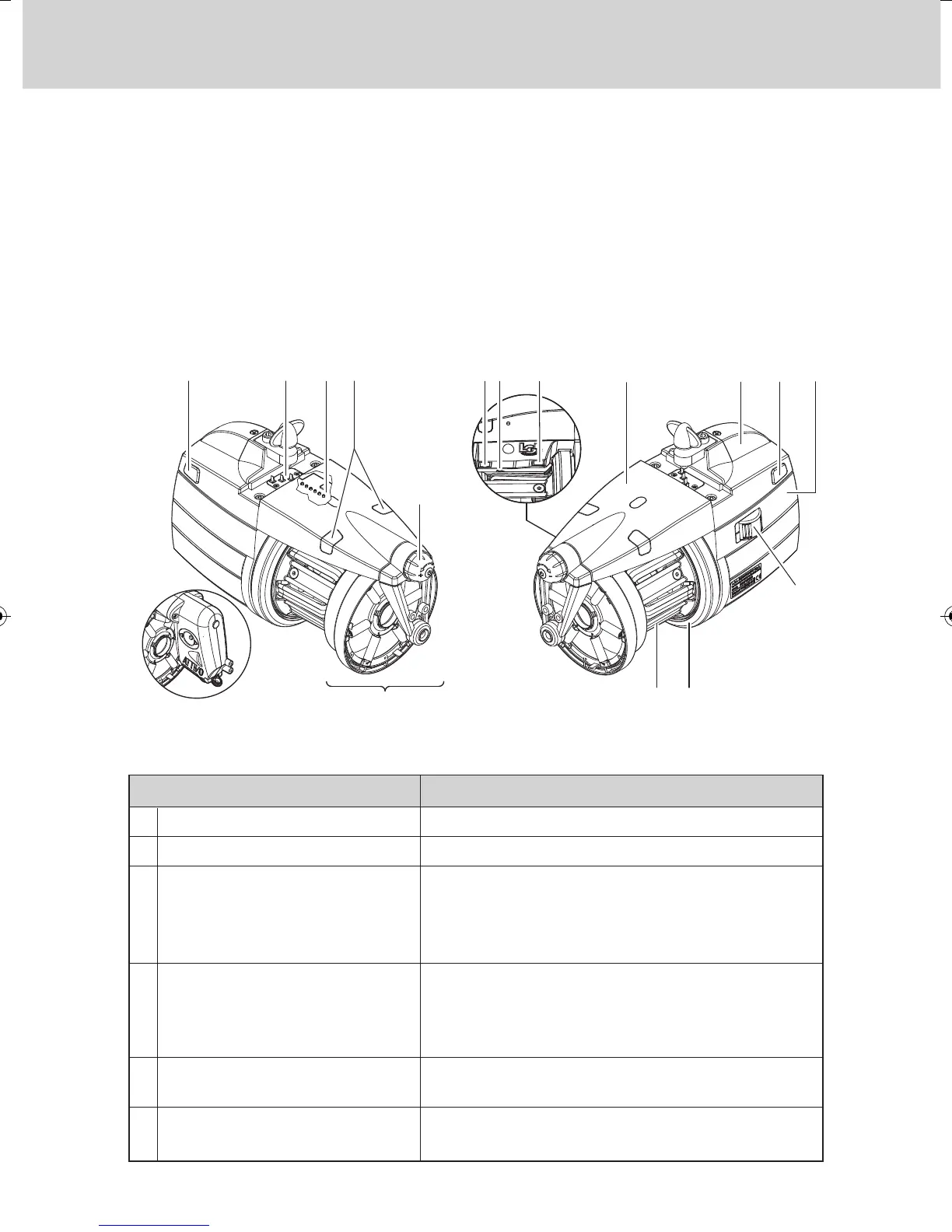

0 – I SWITCH

SERIAL COMMUNICATION PORT

SIGNAL LAMPS

DIP SWITCH

ADJUSTING TWIST-KNOB

THREE-WAY CONNECTOR

• Switches the yarn feeder ON and OFF.

• Enables Pocket and PC interfacing.

• If yarn feeder is turned on and there are

no malfunctions, they will not light up.

• They will light up if any malfunction arises.

(consult paragraph 9 “Trouble shooting”).

• Enables adjustment of the optical sensor’s sen-

sitivity range, reverse the direction of rotation,

self-calibrate magnetic sensors and perform the

termination of the serial bus (see chapter 4.1).

• Enable adjustment of the outbound yarn

tensioning.

• Enables connection of an output yarn feeler

(see chapter 1.8).

A

B

C

D

E

F

CONTROLS / ADJUSTMENTS FUNCTION

FOR FURTHER DETAILS CONCERNING

THE ATTIVO ELECTRONIC TENSIONS,

PLEASE GO TO CHAPTER 7

Loading...

Loading...