Service Manual

57

3 Troubleshooting (continued)

Gas valve adjustment procedure

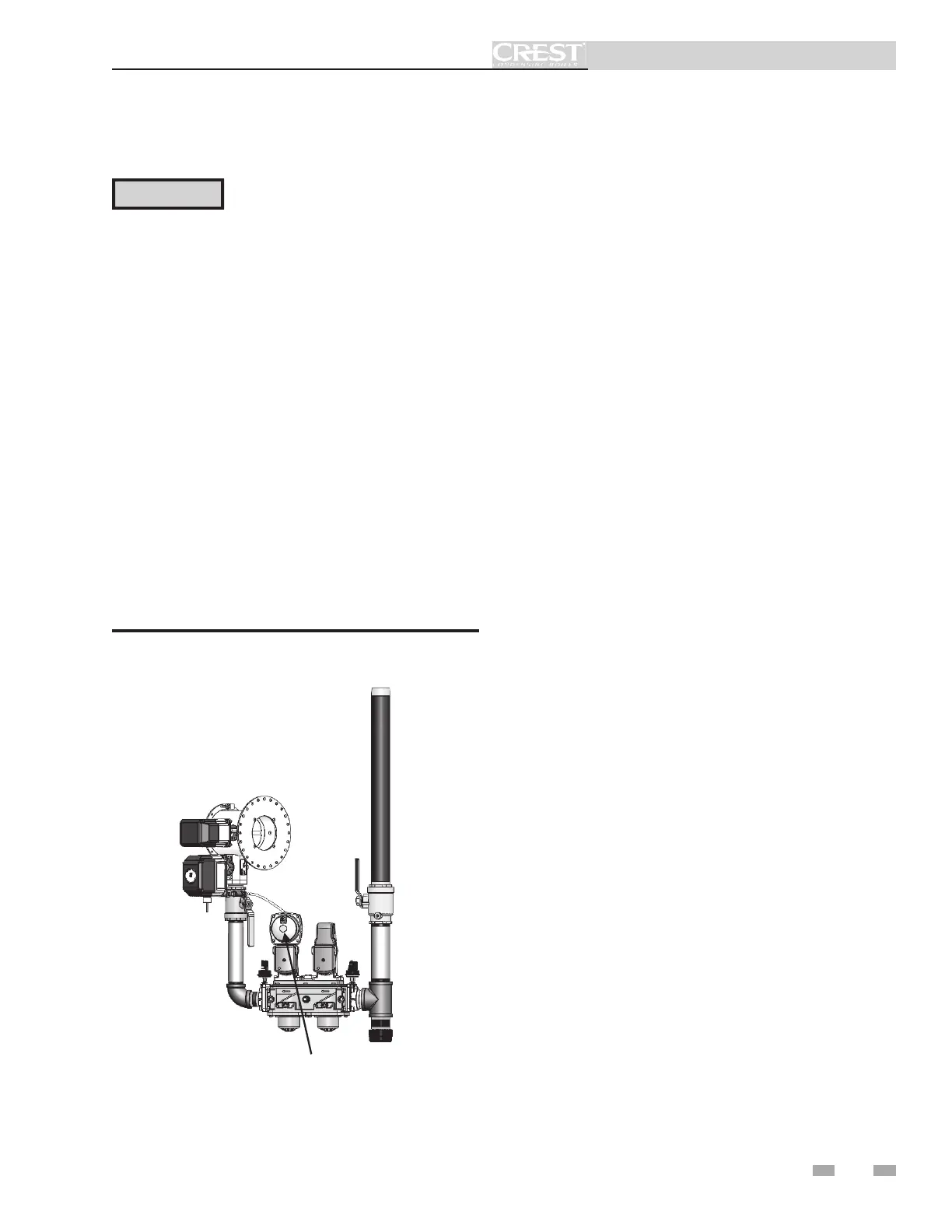

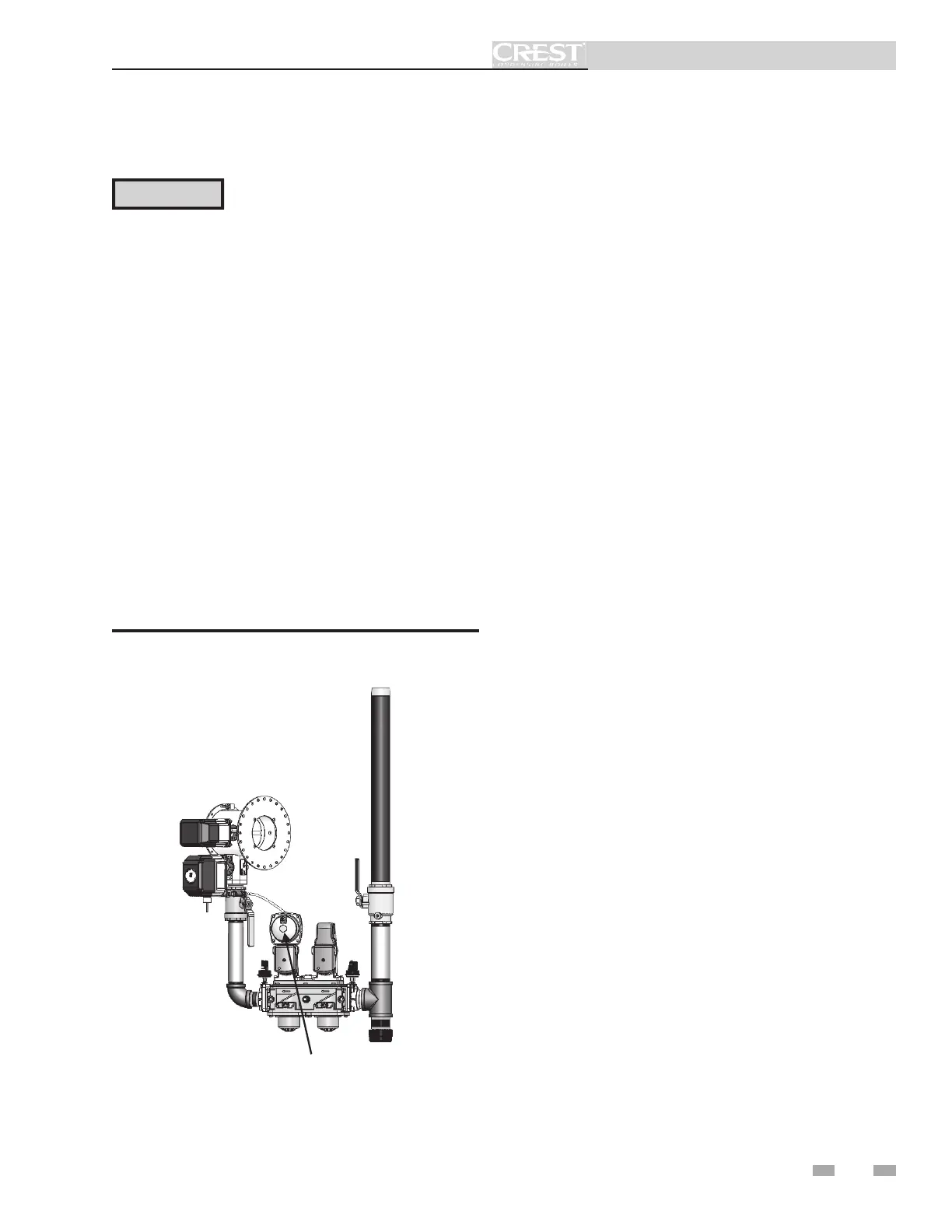

Adjusting the gas valve's regulator adjustment screw (see

FIG. 3-3) sets the manifold pressure used for the entire

modulation range. The commissioning process allows each

of the nine (9) control points to be adjusted individually.

Note: Turning the adjustment screw clockwise increases

the CO while decreasing the O2 levels.

Note: Turning the adjustment screw counterclockwise

decreases CO while increasing the O2 levels.

If combustion is still not within the specified range, repeat

the procedure above. If after four (4) adjustments and the

combustion is still not within the specified range, revisit

the possible causes in Table 3I on page 56 or gas valve

replacement may be required.

CAUTION

Under normal operating conditions the

gas valve should not need adjusting.

Any adjustment should be done in

conjunction with the commissioning

sequence as detailed in the Start-up

Section of the Crest Installation and

Operation Manual.

REGULATOR ADJUSTMENT SCREW

Figure 3-3 Gas Valve Adjustment_Regulator

Adjustment Screw

Loading...

Loading...