3 Troubleshooting (continued)

Service Manual

55

Combustion Analysis Procedure

1. Turn the main power off to the boiler by placing

the “On/Off” switch in the OFF position.

2. Remove the fitting from the flue collector.

Note: Combustion measurements will be

made at this point.

3. Insert the probe from a combustion analyzer

into the hole left by the removal of the fitting.

4. Turn the main power on to the boiler by placing

the “On/Off” switch in the ON position.

5. Navigate to the Setup Screen from the Home

Screen by pressing the SETUP button along

the left side of the screen. Enter the installer

password.

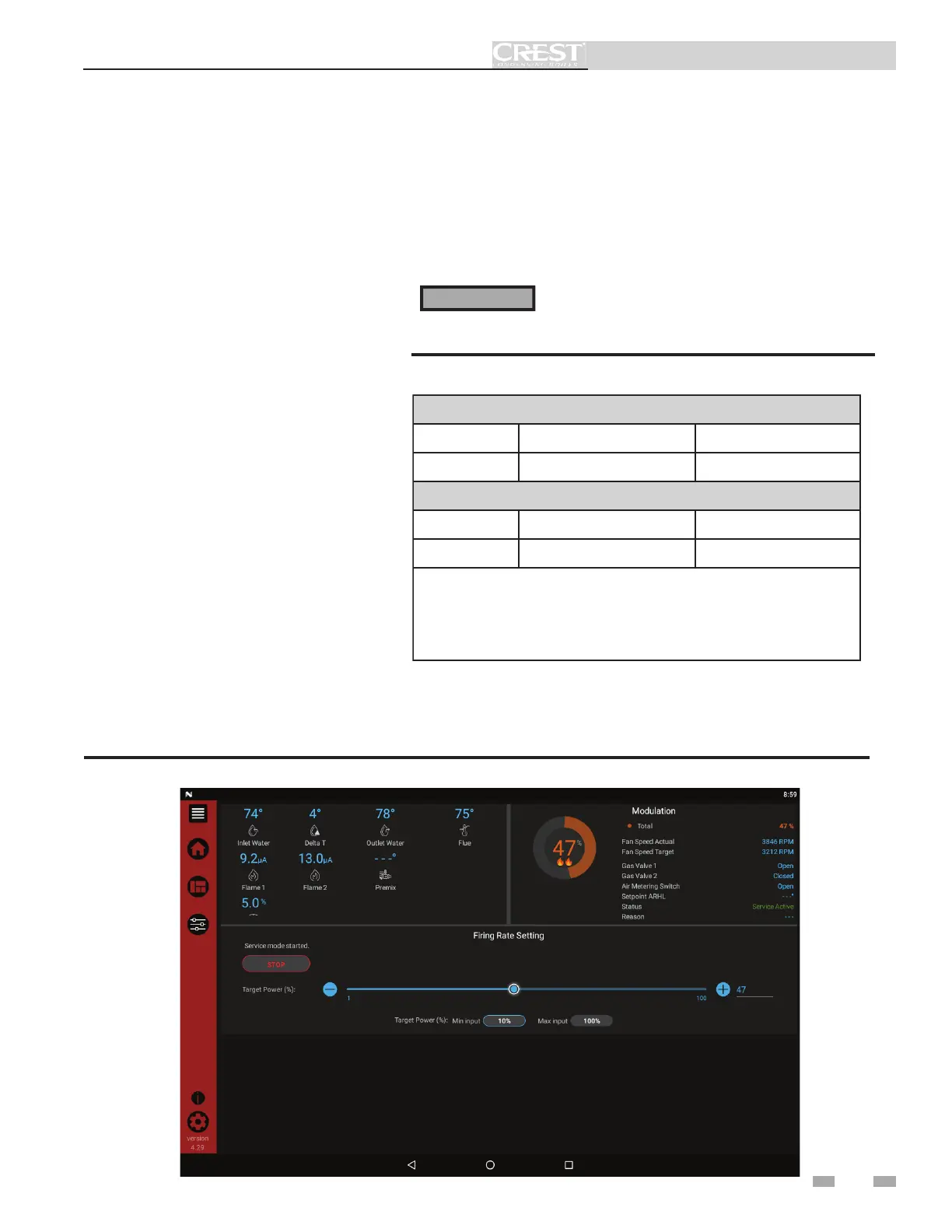

6. Select the Service Maintenance Screen. The

tabs will scroll (up and down) to reveal more

options.

On the Service Maintenance Screen place

heater into Service Mode by selecting the

START button, then selecting the low fire

modulation point (FIG. 3-2).

7. Once the boiler has modulated to rate, measure

the combustion. The values should be near the

target listed in Table 3H (this page). CO levels

should be less than 200 ppm for a properly

installed unit. If the combustion is not near the

target, reference the Troubleshooting Chart for

possible causes and corrective actions.

Table 3H Flue Products

Figure 3-2 Service Screen

You must replace the fitting to prevent flue gas spillage

into the room. Failure to comply could result in severe

personal injury, death, or substantial property damage.

⚠ WARNING

8. Once the heater analysis is complete, test the safety shutoff device by

turning the manual shutoff valve to the OFF position and ensuring the

heater shuts down and registers an alarm. Open the manual shutoff

valve and reset the control.

9. Turn the main power off to the boiler and replace the fitting into the

flue pipe connection.

10. Ensure the boiler is placed back into normal operation.

Natural Gas

Units

*Co๙ (Flue Port)

*O

๙

(Sensor)

ALL 9.5 3.6

Propane

Units

*Co๙ (Flue Port)

*O

๙

(Sensor)

ALL 10.5 4.4

*NOTE: The Hellcat Combustion System is designed to maintain

constant combustion. CO is the target combustion measured from the

flue measurement port. O is the target measurement of the active O

sensor in the combustion chamber. An O2 measurement from the flue

will vary from the O measured in the combustion chamber.

Loading...

Loading...