Welding process

909.4119.9-02 - 31 -07.19

19 Secondary parameter / machine congura-

tion button

A short button press is used to activate the

secondary parameter menu.

The machine conguration menu can be

activated from the secondary parameter

menu by pressing for an additional 2 sec.

A short button press ends the respective

menu level.

20 On/O button (2 sec.)

Switches the device on or into Standby

mode.

21 Display units LEDs

Display whether values in the 7-segment

display 31 values are shown in ampere,

percent, Hertz or seconds.

22 7-segment display

shows the current selected.

If the secondary parameters are activated,

the code and the set value are shown alter-

nately.

15 Welding process

15.1 Electrode

Before switch-on, ensure that neither

the electrode holder nor the elec-

trode is touching the welding table,

the workpiece or another electrically-

conductive object, to ensure that you

do not unintentionally ignite arcing on

switch-on. An unintentionally ignited

arc can damage the electrode holder,

the welding table, the workpiece and

the machine

Switch on the system

If necessary, switch the system on by pressing

button 20 for 2 sec.

Keep pressing button 19 until the desired pro-

cess is selected.

The MMA or CEL electrode icon (LED 15 or 16)

lights up.

Use control knob 14 to set the desired welding

current.

Arc ignition

Briey touch the workpiece at the point to be

welded using the electrode and lift the elec-

trode a little.

The arc burns between the workpiece and the

electrode.

Hotstart

In the electrode welding method, a hotstart of

125 % of the set welding current is used for 1

second for ignition. Like the welding current,

the hotstart is limited to a maximum of 180 A.

This can be changed in the secondary param-

eter menu.

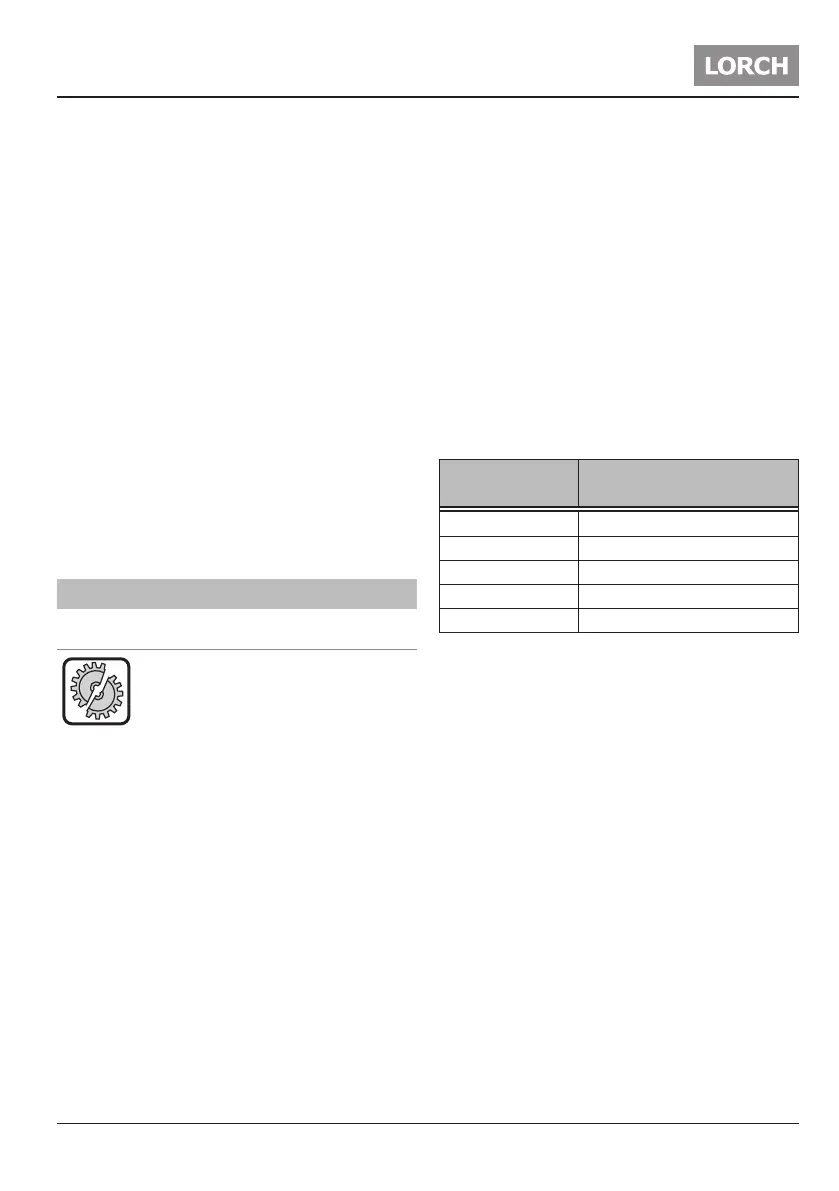

Guide values for current intensity

Electrode Ø

[mm]

Recommended

current intensity [A]

1.5 20...40

2.0 35...60

2.5 45...100

3.2 75...140

4.0 130...190

Pulses

Pulsing can be set separately for each process.

Call up the secondary parameters (see “16 Sec-

ondary parameters” on Page 33).

Select the menu item Pulse Option (code "Pu0")

and set this to "on".

The Pulsing LED 18 lights up.

Select the "Secondary energy" secondary pa-

rameter (code "2.E").

Set the desired secondary current value by us-

ing control knob 14. The setting value is based

on % of the main current I1.

Select the "Pulse frequency" secondary param-

eter (code "PuF").

Set the desired pulse frequency by using con-

trol knob 14.

Select the "Pulse cycle duty" secondary param-

eter (code "PuB").

Loading...

Loading...