Messages

- 36 - 07.19909.4119.9-02

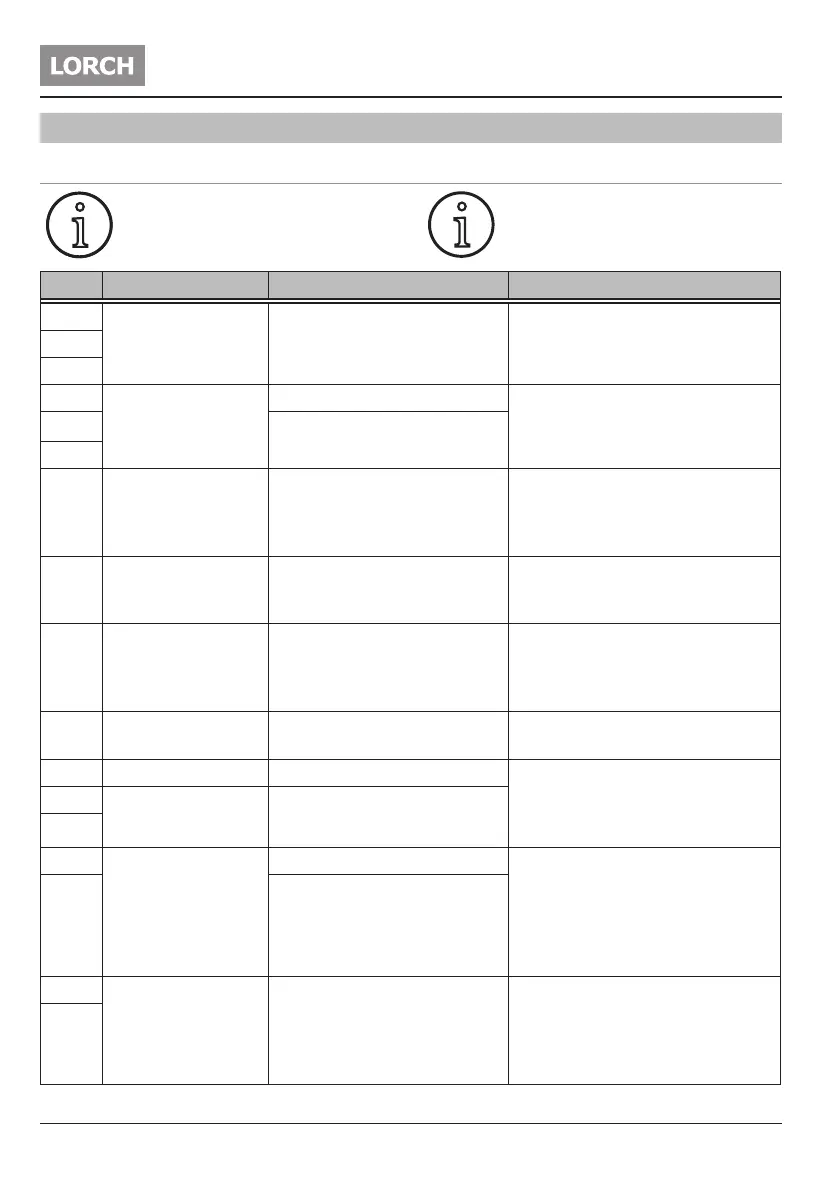

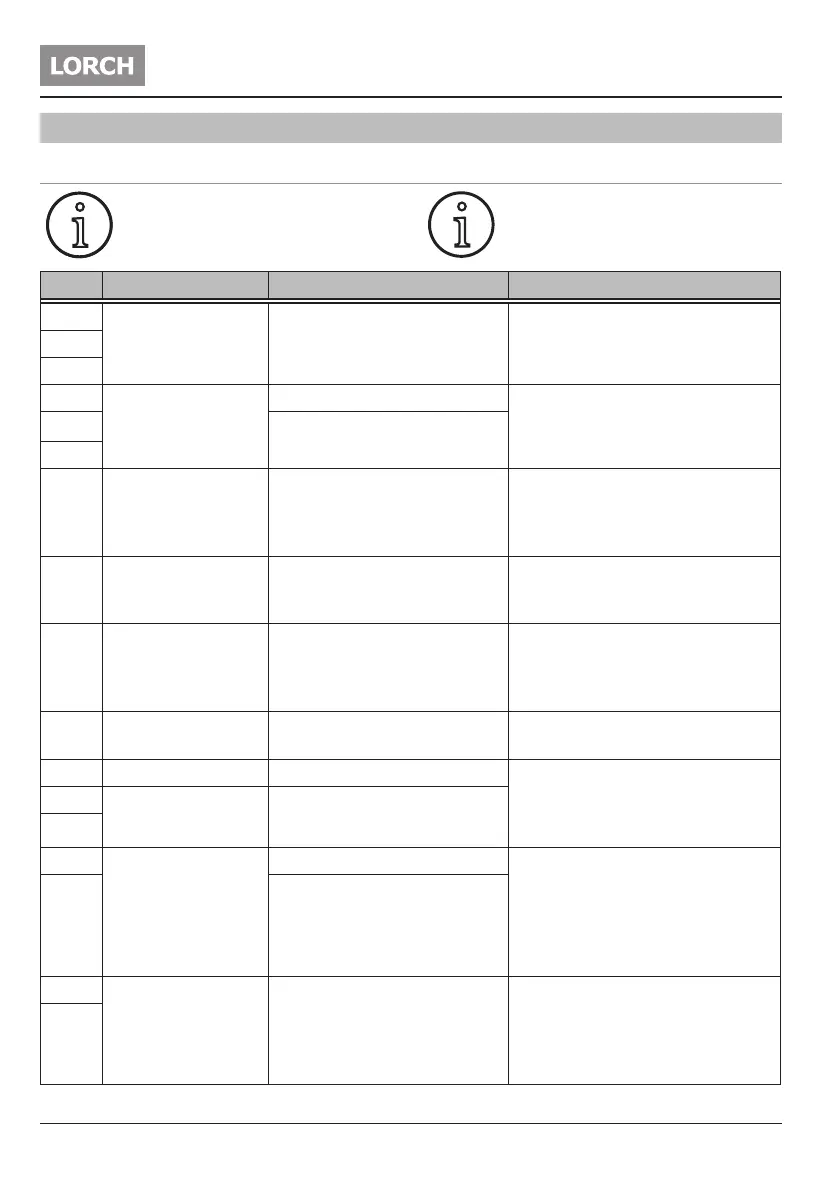

19 Messages

19.1 Error messages

Faults can be reset by switching o

and on again.

As long as there is an error code on dis-

play welding is not possible.

Code Fault Possible cause Rectication

E01-01 Excess temperature The device has overheated, the

permitted switch-on time was

exceeded

Allow switched-on machine to cool

down for a few minutes.

E01-02

E01-05

E02-00 Overvoltage, primary Mains voltage too high Check mains voltage, test device on

another power socket.

E02-01

Internal working voltage too

high

E02-02

E04-05 PFC error Internal mains control not work-

ing

Switch the equipment o and on

again. Inform the customer service

in the event of a repeated or perma-

nent fault message

E06-00 Overvoltage second-

ary

Initial voltage too high Check the work piece. Inform the

customer service in the event of a re-

peated or permanent fault message

E07-01 Internal EEProm fault Internal accummulator faulty Switch the equipment o and on

again. Inform the customer service

in the event of a repeated or perma-

nent fault message

E11-00 Fault in remote con-

trol

Defect in remote control or

remote control socket

Check or replace the remote control

E12-00 Fault in Power unit Power section start-up faulty Switch the equipment o and on

again. Inform the customer service

in the event of a repeated or perma-

nent fault message

E13-01 Thermal sensor Internal temperature sensor

defective

E13-02

E14-00 Primary undervoltage internal supply voltage too low Check mains voltage, test device on

another power socket. Switch the

equipment o and on again. Inform

the customer service in the event

of a repeated or permanent fault

message

E14-01 Internal operating voltage too

low when powering on

E15-00 Current measurement Error in internal power measure-

ment

Check torch and work piece con-

nections. Switch the equipment o

and on again. Inform the customer

service in the event of a repeated or

permanent fault message

E15-01

Loading...

Loading...