page 36

Cooling unit

At watercooled machines, the owrate of the cooling liquid is measured in the return ow. The owmeter output is

a digital signal where it’s frequency is proportional to the owrate. The higher the owrate, the higher the frequen-

cy. If the owrate is below 0.3 liter per minute, the machines will stop and dislays E05 (cooling system error).

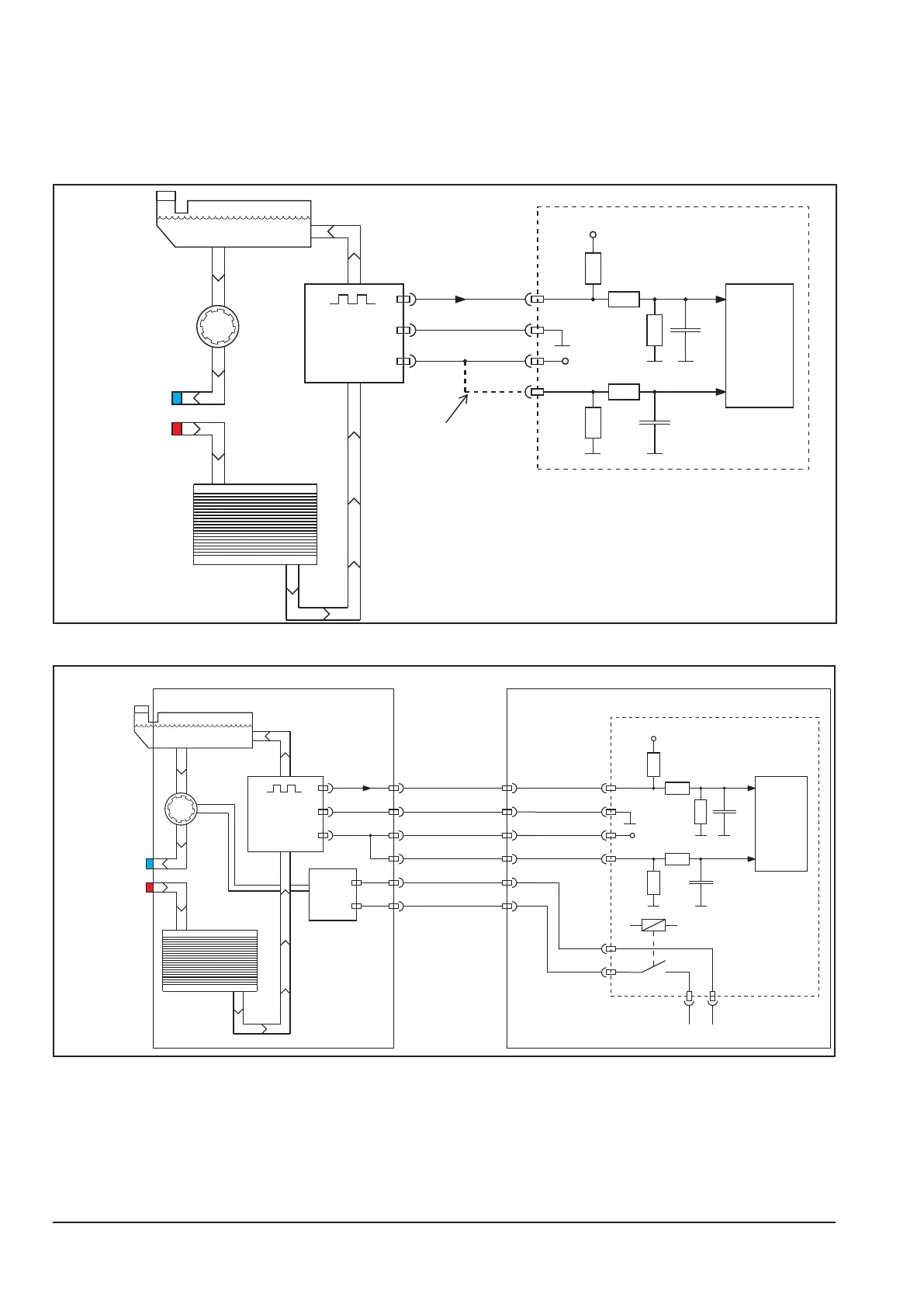

Schematic (internal cooling unit)

X12 / 2

X12 / 3

X12 / 1

X12 / 4

2

3

1

+15V

+15V

MASTER

DK-MAPRO

identification

“gascooled“

tank

pump

hose connector

blue

hose connector

red

flow meter

cooler

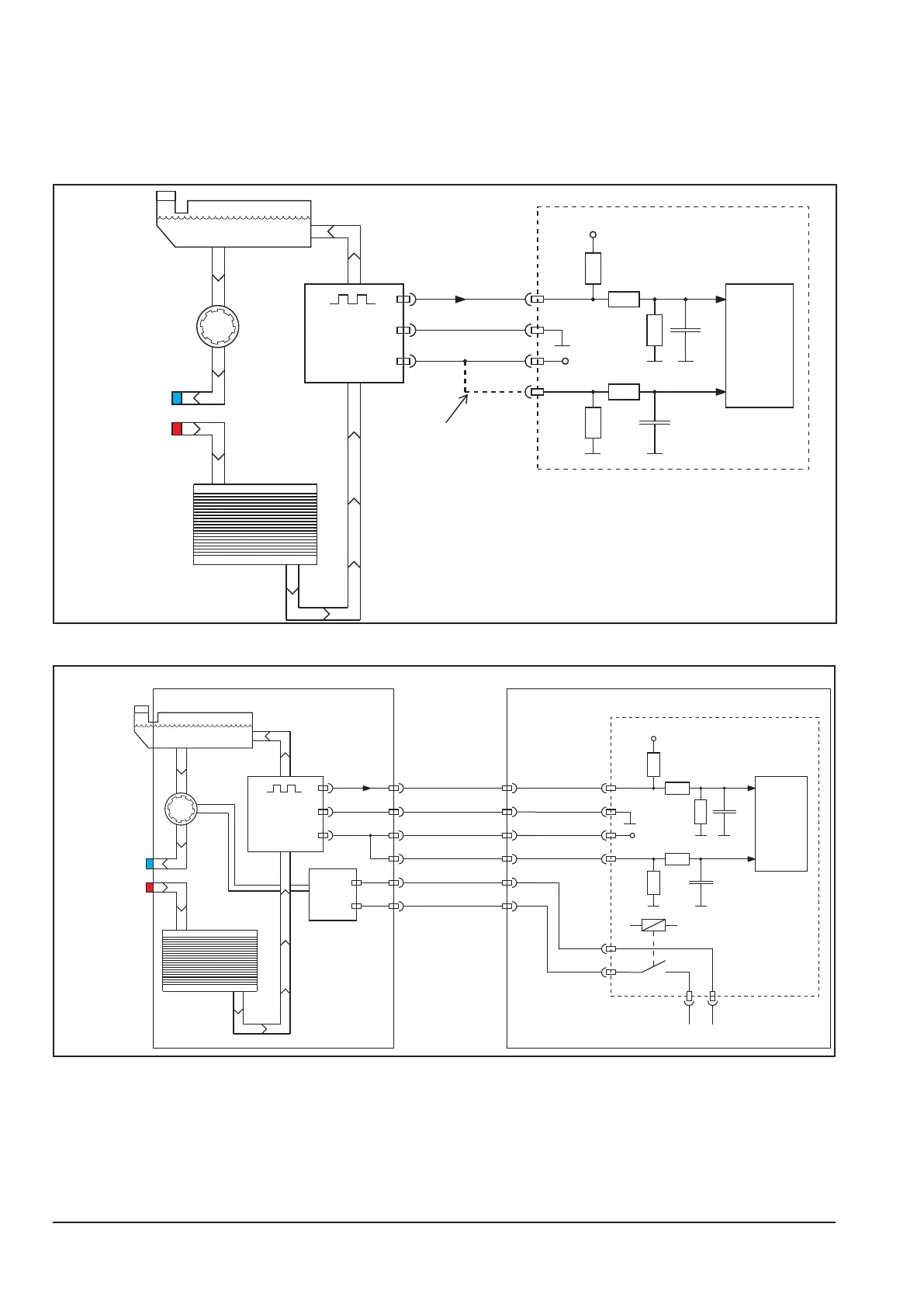

Schematic (external cooling unit “WUK“)

X12 / 2

X12 / 3

X12 / 1

X12 / 4

2

3

1

X1 / 4

X1 / 5

X1 / 3

X1 / 6

WUK

+15V

+15V

MASTER

DK-MAPRO

X7 / 4

X7 / 5

X7 / 3

X7 / 6

X1 / 1

X1 / 2

X5 / 2

X5 / 4

X7 / 1

X7 / 2

X10 / 1

X10 / 2

X6 / 1

X6 / 3

42V AC

power source

tank

pump

hose connector

blue

hose connector

red

flow meter

cooler

At gas cooled machines, a small cable bridge is shorting pins 1 and 4 at connector X12, instead of a ow meter.

This is the identication to deactivate the monitoring of the ow meter.

At the V mobile machines, this identication is used to detect if an external water cooling unit is attached or not.

In this case the cable bridge has the opposite meaning: “water cooled“. This is the reason for setting the DIP

switch 4 on the DK-MAPRO board:

OFF = internal cooling system (“driveable machines“)

ON = external cooling system (“mobile machines“)

Loading...

Loading...