Pump Installation 5352 Pump Installation

EN EN

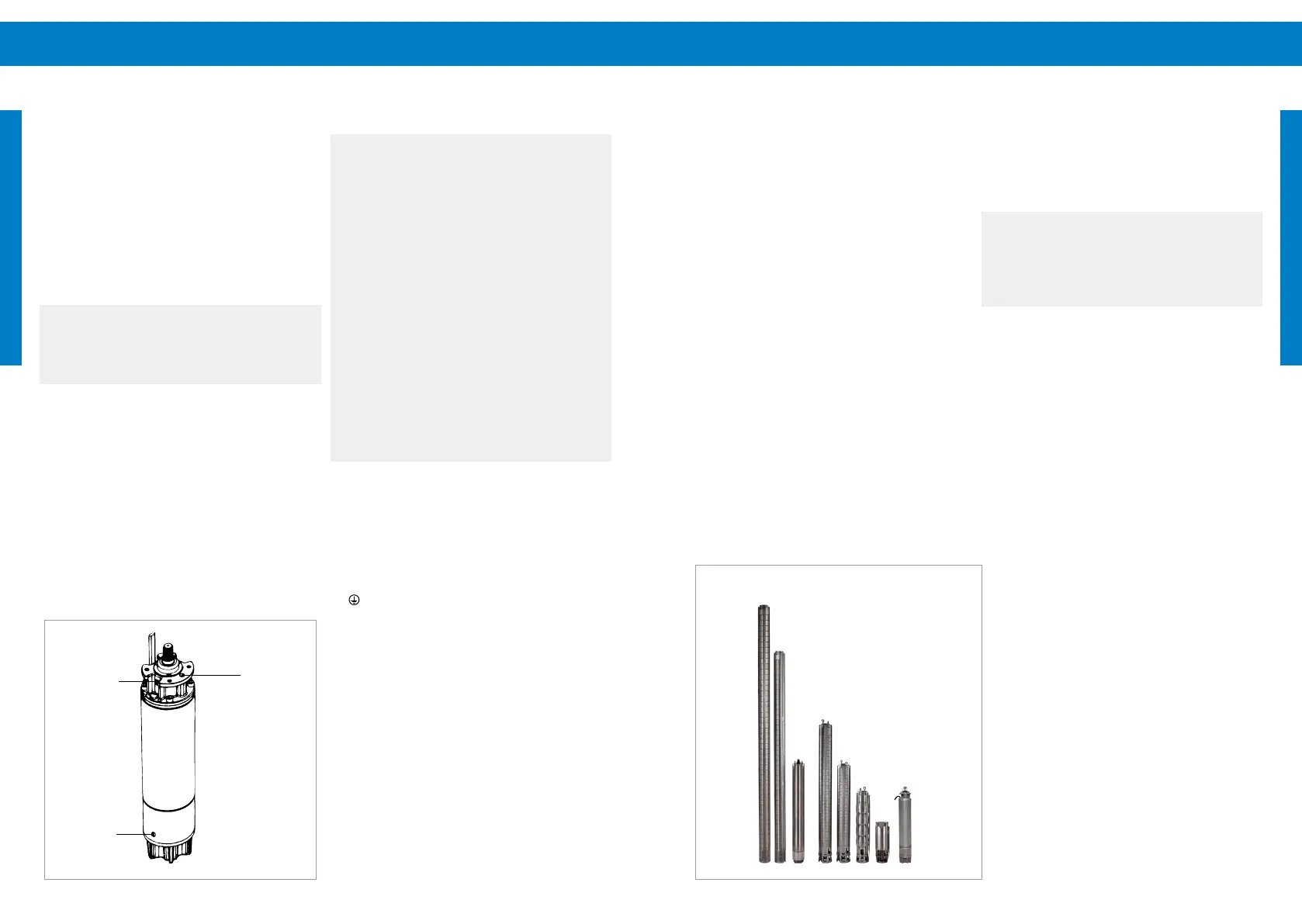

venting

hole

lling

hole

drainage

hole

Centrifugal Pumps:

Check of rotation direction after submersible pump

installation:

(5) Connect the pump to the controller and power

supply.

(6) Start the pump and check the delivered ow

rate.

(7) Stop the pump, disconnect the power supply and

change two of the three phase leads

(8) Start the pump again and check the delivered

ow.

(9) Stop the pump, disconnect the power supply

and compare the ow rates from point 2 and 4.

The wiring with the better ow rate has the right

rotational direction.

Figure 20: Example LORENTZ PSk3 submersible

pumps

8.2.3 Resistance measurement

We recommend checking the winding and

insulation resist ance before connecting the pump

to the controller. For a submersible pump these

measurements should be done BEFORE lowering the

pump into the well.

l

WARNING – Before starting any work

on the pump system, make sure that

the electricity supply has been switched

o and that it cannot be accidentally

switched on!

To measure the winding and insulation resistance

disconnect all motor leads from the controller. A

good quality multimeter is necessary to measure the

phase-to-phase resistance with an accuracy to the

rst decimal place. (“0.1 Ohms”). It is also advisable

to consider the resistance of the multimeter leads

when measuring very low values:

Hold the tips of the multimeter together and

note the value.

Always substract this value from your motor

resistance measurements!

The submersible motor is factory-lled with water,

but the motor lling must be checked before

installation.

The motor must be lled in vertical position (coupling

showing upwards, see gure below, "Figure 19:

Filling, venting and drainage hole").

To ll the motor with water, remove the lling and

venting screw. Fill clean drinking water into the

motor until the water ows out continuously out of

the venting hole, without any bubbles.

a

NOTE – Do not ll the motor using a

high pressure source such as a tap or

hose as this will cause unwanted bubble

formation.

To rell the motor open the lling, venting and

drainage screws to allow water to exit from the

drainage hole. Close the drainage screw and ll the

motor with clean drinking water as described above.

Figure 19: Filling, venting and drainage hole

8.2.2 Wiring the pump

a

CAUTION – No disconnect switches

must be installed between the motor

and the pump controller. Connecting the

motor wire to the switched-on controller

might irreparably damage it. Such

damage is excluded from the warranty.

CAUTION – If the pump wires are in

the wrong order, the motor will run in

reverse and the pump will not function

correctly. Damage may result. Check the

direction before installing the pump.

The proper direction is counterclockwise

when viewed from above.

CAUTION – Never let the pump run

dry. Dry running will damage the pump

and void the warranty. LORENTZ requires

dry run protection for every submersible

pump system.

The motor cables of the pump have a marking to

allow correct wiring. Connect the wires using this

sequence:

U: Motor cable phase 1

V: Motor cable phase 2

W: Motor cable phase 3

: GND

The submersible pump must be submerged in water

before checking the correct rotational direction. The

correct rotation direction for submersible pumps

is counterclockwise, viewed from the top. It is also

labelled with an arrow on the pump end.

Loading...

Loading...