Pump Accessories Installation 7978 Pump Accessories Installation

(a) PSk3 CS-F

(b) PSk3 CS-F1 to F20

(c) PSk3 CS-G

EN EN

sealed cable

clamp

position pump

o

pumping

range

position pump

on

cable

weight

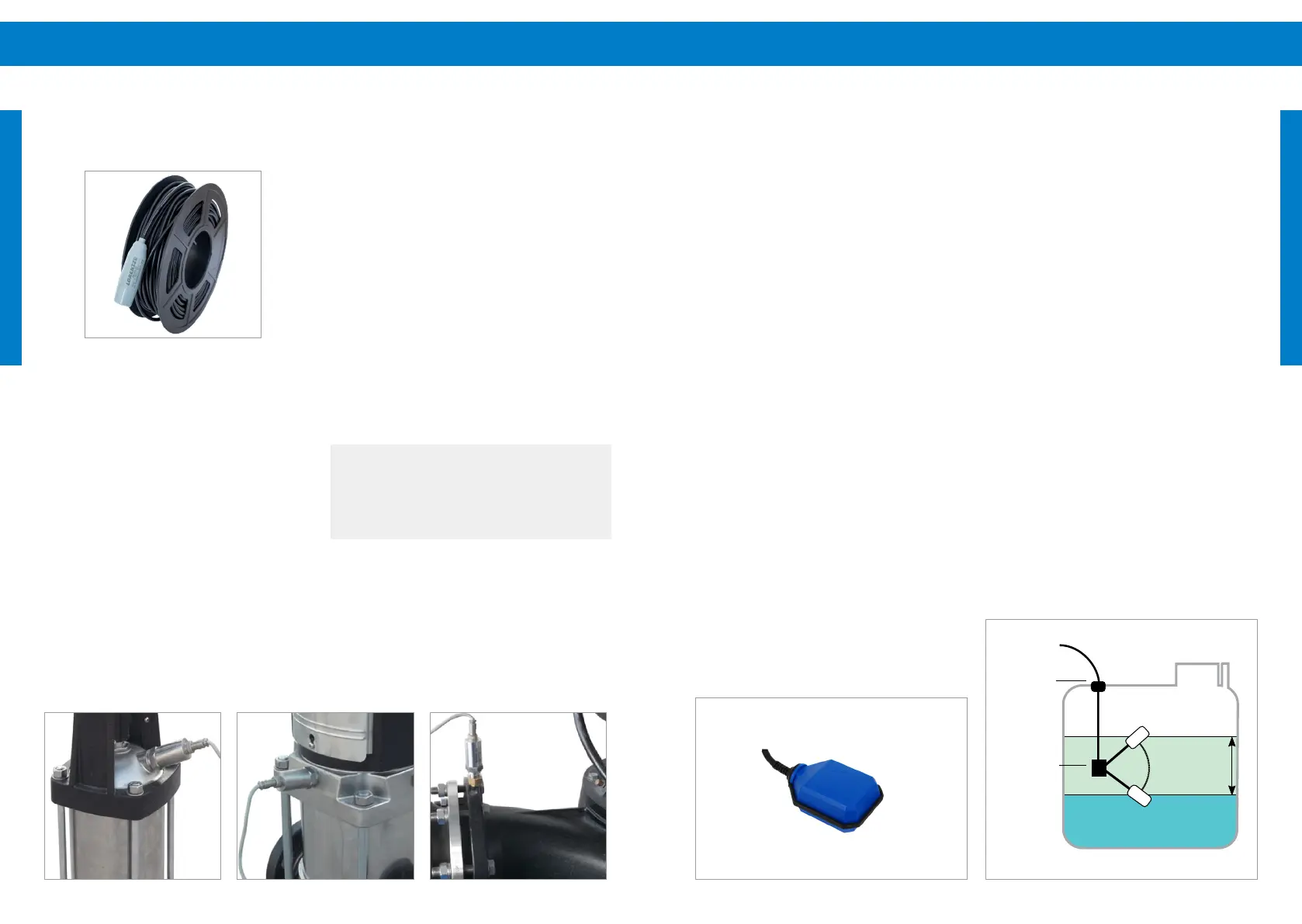

9.7 Float Switch (Full Tank Shut-o)

We recommend the use of a oat switch or other

means to prevent overow of your tank. This will

stop the pump when the tank is full, then reset

when the level drops. This conserves ground water,

prevents overow, and eliminates unnecessary

pump wear. PSk3 controllers allow the use of a small

signal cable to a remote oat switch, even if the tank

is a long distance away.

Float switch requirements:

We recommend installing a surge protector to avoid

possible surges (e.g. from lightning) from the oat

switch cable into the controller.

(1) A switch must be used, not wet electrodes.

(2) The preferred system requires a oat switch to

OPEN contact on rise to turn the pump OFF. This

is called “normally closed” (N.C.).

Figure 50: Float switch

Float switch cable requirements:

(1) Two wires are needed.

(2) Minimum wire size 1 mm² / AWG 18. This is good

for a distance as far as 600 m / 2,000 ft.

(3) The cable must be suitable for its environment.

(4) If it must run a long distance, use twisted-pair

shielded cable to reduce the chance of damage

from lightning-induced surge.

Grounding shielded oat switch cable – If you use

shielded cable, connect the shield to ground at the

controller only. Do not ground the shield at the oat

switch. This will reduce surges induced by nearby

lightning.

Operation of the oat switch system – When

the water level is high, the oat switch will stop the

pump. The TANK-FULL indicator on the controller will

light up. When the water level drops, the oat switch

will signal this to the controller. The indicator light

will turn o, and the pump will restart if sucient

power is available.

Figure 51: Float switch scheme

For more information about the pressure sensor

range (LPS) please refer to the COMPASS datasheet.

Ensure that the pressure sensor is suitable for

your application regarding pressure range and

temperature resistance.

LORENTZ PSk3 CS-F pump ends allow the

installation of the pressure sensor at the pump

housing. This is a simple alternative compared to the

conventional pipeline installation.

For the pump types LORENTZ PSk3 CS-F1 to

CS-F20 it is necessary to remove the vent plug

to install the pressure sensor. Therefore install

the pressure sensor after the pump is lled with

water, see chapter "8.3.5 Initial Start-up" on page

69.

All other LORENTZ PSk3 CS-F pump types have

a second ller plug which can be replaced by a

pressure sensor.

Figure 49: Pressure sensor installation

a

CAUTION – The connection thread

size at the pump housing of the CS-F

pumps is G1/2”. The connection thread

size at the pump housing of the CS-G

pumps is G1/4”.

CS-G pump ends allow the installation of the

pressure sensor at the anges of the suction and

pressure side.

Figure 48: Water Level Measurement Solution

9.6 Pressure sensor installation

The LORENTZ range of liquid pressure sensors are

used to measure the pressure in a pipe. The sensors

are commonly used to measure the pressure at a

well head or feeding into irrigation systems. The

liquid pressure sensor can also be used in constant

pressure applications and as a pressure switch.

Please refer to partnerNET for more information.

Loading...

Loading...