Pump Installation 6968 Pump Installation

EN EN

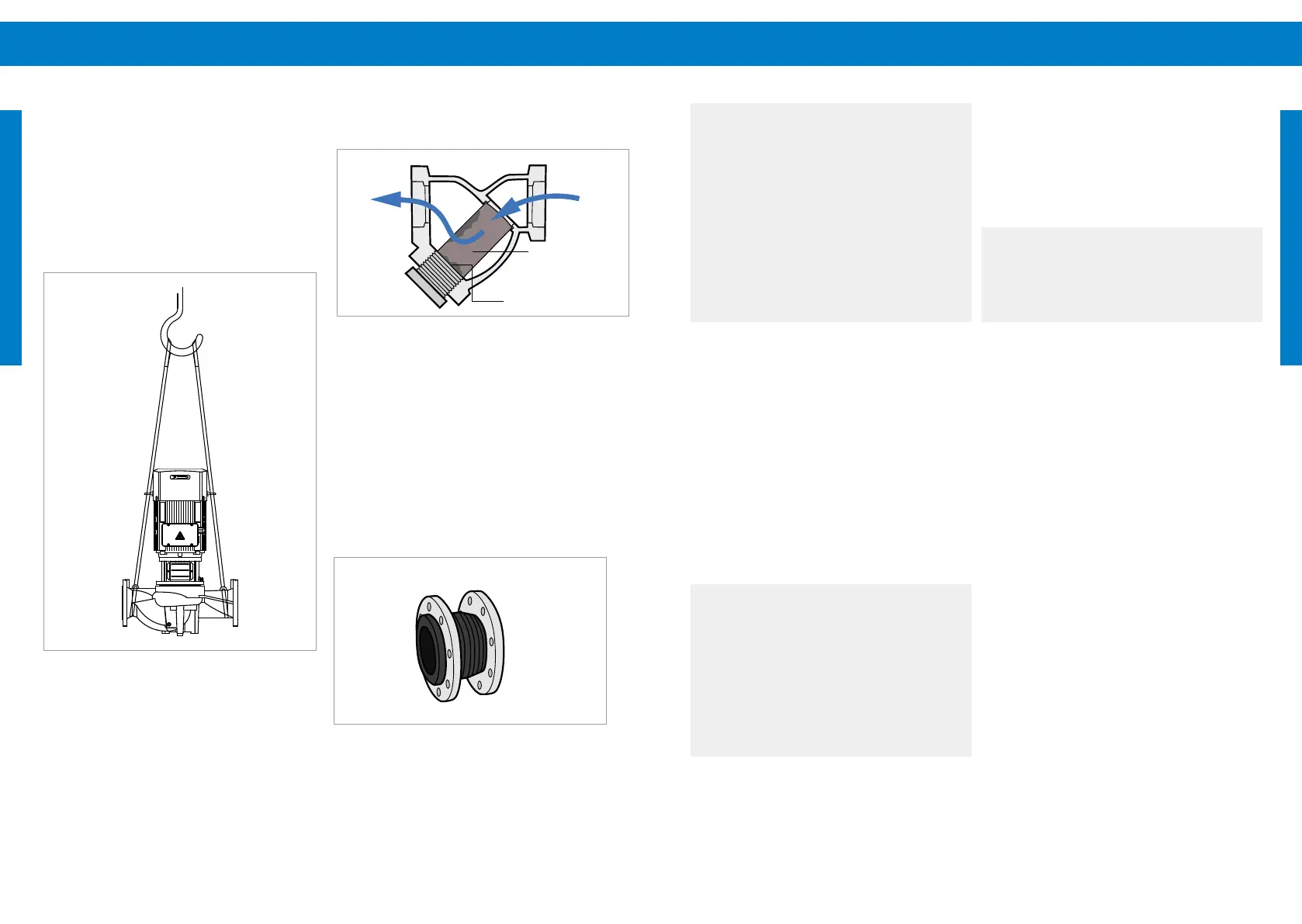

lter element

particle accumulation

l

WARNING – Inlet and outlet pipes

must be mounted to the pump housing

free of tension.

a

CAUTION – Make sure that the

suction pipe is sealed with no leaks,

otherwise the pump will not prime or will

prime insuciently.

CAUTION – The pumps are shipped

with plastic covers on the pump inlet and

outlet. Remove them before connecting

the pipes to the pump.

Check valve – A check valve at the inlet pipe is

needed to assure that the pump and its suction

pipeline remains completely water lled during

the time the pump is switched OFF. Always install a

check valve with one inch (1”) larger diameter than

the suction pipe in order to avoid too much suction

pressure drop. For example if the suction pipe size is

3”, then a 4” check valve should be installed.

8.3.4 Suction Head

The maximum suction head is limited by the local air

pressure, the water temperature of the medium, the

pipe losses and the NPSH (net positive suction head)

value of the pump.

a

CAUTION – If the suction pressure

in the pump is lower than the vapor

pressure of the uid, cavitation will

occur. Cavitation creates noise and

will damage the pump. Damage due to

cavitation is not subject to warranty.

To avoid cavitation, the pressure of the

uid must be maintained above its vapor

pressure at all points as it passes through

the pump.

The maximum suction head (H) must be calculated

in advance. Please refer to COMPASS and the

corresponding LORENTZ knowledge base article for

NPSH calculation.

8.3.5 Initial Start-up

a

CAUTION – Never start the pump if it

is not lled with water and has not been

vented. The pump and suction pipe must

be fully lled with clean water otherwise

the pump will be damaged.

8.3.5.1 Filling Pump with Water

The pump and the whole suction pipe must be fully

lled with clean water.

If the water level is higher than the pump inlet:

1. Close the gate valve in the outlet pipe and

loosen the air vent screw.

2. Open the gate valve in the suction pipe slowly.

3. Tighten the air vent screw when water streams

out continuously.

If the water level is below the pump inlet:

Suction pipeline and pump must be lled with water.

1. Close the gate valve in the outlet pipe and open

the gate valve in the suction pipeline.

2. Loosen the air vent screw and ll the water into

the pump through the ller pipe.

3. Fasten the air vent screw after the pump and

the suction pipeline are completely lled with

water.

Pipe system – We advise that pipe expansion

joints are used close to the pump on both inlet

and outlet to reduce noise and vibration (see also

"Figure 35: Pipe expansion joints" on page 68). It

is recommended that you install a gate valve in the

suction and discharge pipeline close to the pump to

avoid draining of the pipe while cleaning (e.g. lters),

repairing, servicing or replacing the pump system.

Figure 34: Strainer 8.3.3 Installation and Handling

Handling – When lifting the CS-F pump use the

eyebolts at the motor housing. CS-G pumps must be

lifted by the base. Use the eyebolts to stabilize the

pump, see also "Figure 33: Pump handling/lifting"

below. It is recommended to use suitable lifting sling

belts.

Figure 33: Pump handling/lifting

Strainer – If pipelines are welded together metal

pieces might be present in the pipeline. Before pump

installation, the inlet pipeline must be carefully

cleaned. It is recommended to install a strainer

about 1 m / 3 ft in front of the pump inlet to avoid

pump damage due to any kind of impurities (see also

"Figure 34: Strainer" on page 68). The pressure

drop of the strainer must be considered in the

suction head calculation. Please refer to COMPASS

and the corresponding LORENTZ knowledge base

article.

Figure 35: Pipe expansion joints

unltered ow

ltered

ow

Loading...

Loading...