Pump Accessories Installation 7776 Pump Accessories Installation

10×D 5×D

D

EN EN9.3 Water meter installation

For information on the water meter installation,

please refer to the manual of the manufacturer. Pay

attention to the installation position, ow direction

and the calming section.

Basic rule: The water meter should have 10 nominal

diameters straight pipe ahead of the meter and 5

nominal straight pipe diameters after to ensure

proper ow through the meter.

Figure 45: Water meter installation

Figure 46: LORENTZ water meter

9.4 Level sensor installation

The LORENTZ range of liquid level sensors use

pressure to measure the level of water in a well

or tank. The sensors can be used for long term

water level monitoring and also for pump control in

applications where a well probe cannot be used.

The Level sensor is connected to one of the two

Analog Inputs of the controller. Conguration of the

sensor is done with LORENTZ Assistant.

For further information about the level sensor please

refer to the COMPASS datasheet.

Figure 47: LORENTZ Liquid Level Sensor

9.5 Water Level Management Solution

(WLMS) installation

The LORENTZ Water Level Measurement Solution

(WLMS) accurately measures water levels in

boreholes and tanks. WLMS is a combination of

pressure sensor and plug-in barometer to provide

water level measurement for PS2 and PSk3 systems.

Used in conjunction with inbuilt software WLMS

allows you to record and monitor water levels in your

tank and control your system based on these levels.

For further information about the level sensor please

refer to the COMPASS datasheet and the WLMS

manual for installation and operation.

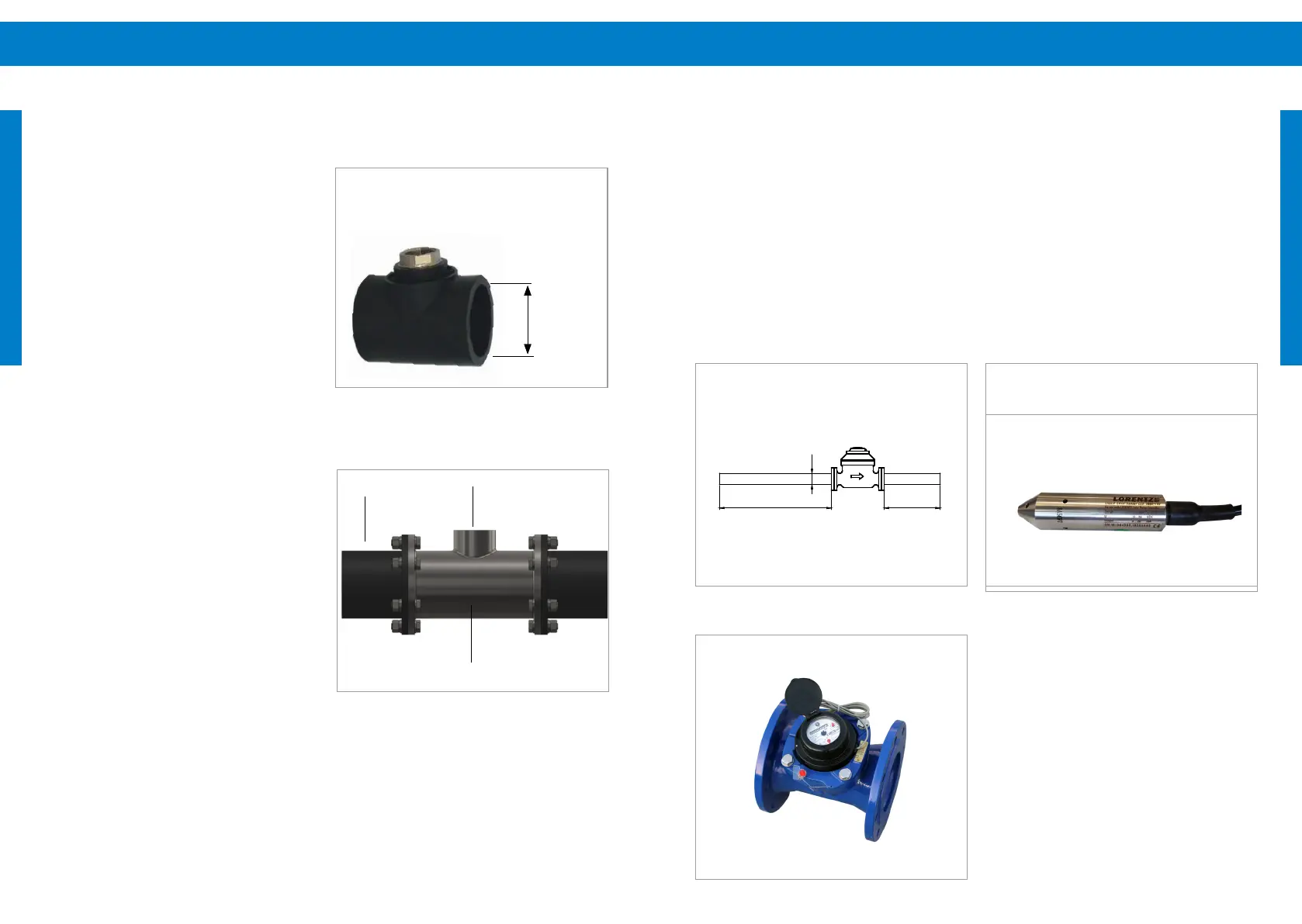

9.2.3 HDPE pipe

Option 1: Weld a tee-piece into the HDPE pipe, see

also „Figure 43: HDPE pipe tee-piece“ on page 76.

The tee-piece must have a 1” female thread (G1”,

whitworth pipe thread). The pipe diameter of the

tting should be the same as the pipe size. This piece

will be welded into the pipeline.

The tee-piece described above is not delivered by

LORENTZ.

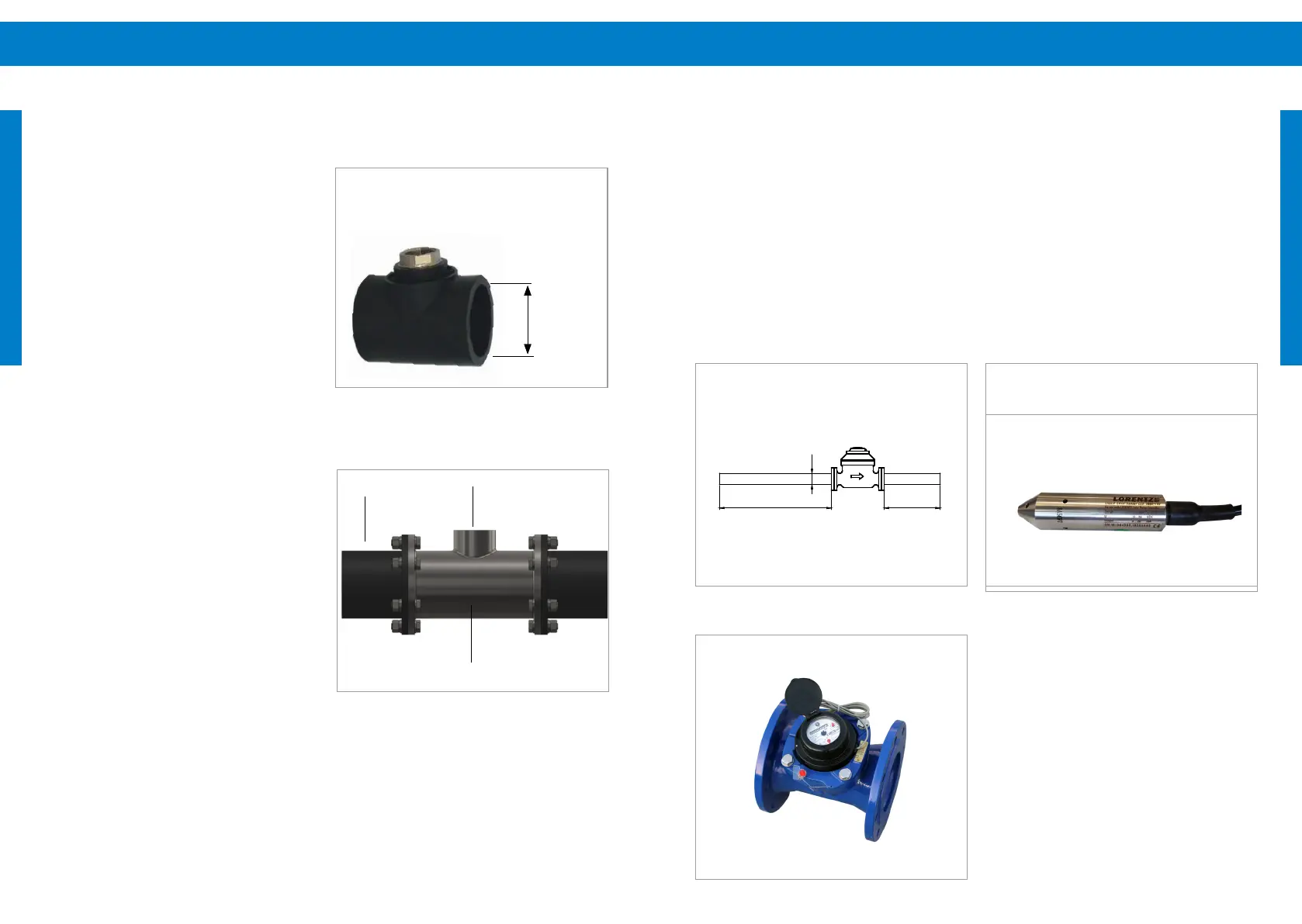

Option 2: Install an additional piece of steel or

stainless steel pipe with anges on both sides of the

HDPE inlet pipeline, see also „Figure 44: Steel ange

with adaptor in HDPE pipe“ on page 76 . Weld the

steel/stainless steel adapter for the water sensor on

the steel/stainless steel pipe according to chapter

"9.2.2 Steel/Stainless steel pipe" on page 74.

The steel / stainless steel pipe is not delivered by

LORENTZ.

After completion of option 1 or option 2, continue

with step no. 2. of chapter "Pipe system – We advise

that pipe expansion joints are used close to the

pump on both inlet and outlet to reduce noise and

vibration (see also „Figure 35: Pipe expansion joints“

on page 68). It is recommended that you install

a gate valve in the suction and discharge pipeline

close to the pump to avoid draining of the pipe while

cleaning (e.g. lters), repairing, servicing or replacing

the pump system.

Figure 43: HDPE pipe tee-piece

Figure 44: Steel ange with adaptor in HDPE pipe

1“ female thread (Whitworth pipe thread)

for the sensor housing

pipe diameter

D

HDPE pipe

adapter

steel / stainless steel

pipe

Loading...

Loading...