Pump Installation 6766 Pump Installation

EN ENExample:

Motor:

AC DRIVE CS-F 7.5 kW 1.4 Ω

Motor cable:

150 m and 6 mm

2

0.25 Ω / 100 m

Calculation of expected phase-to-phase

resistance:

= 1.4 Ω + 2 × 150 m × 0.25 Ω / 100 m

= 1.4 Ω + 2 × 0.375 Ω

= 1.4 Ω + 0.75 Ω

= 2.15 Ω

= ~ 2.2 Ω

The real measured values can be dierent,

depending on the measurement equipment

and materials that are used. This is just an

approximation.

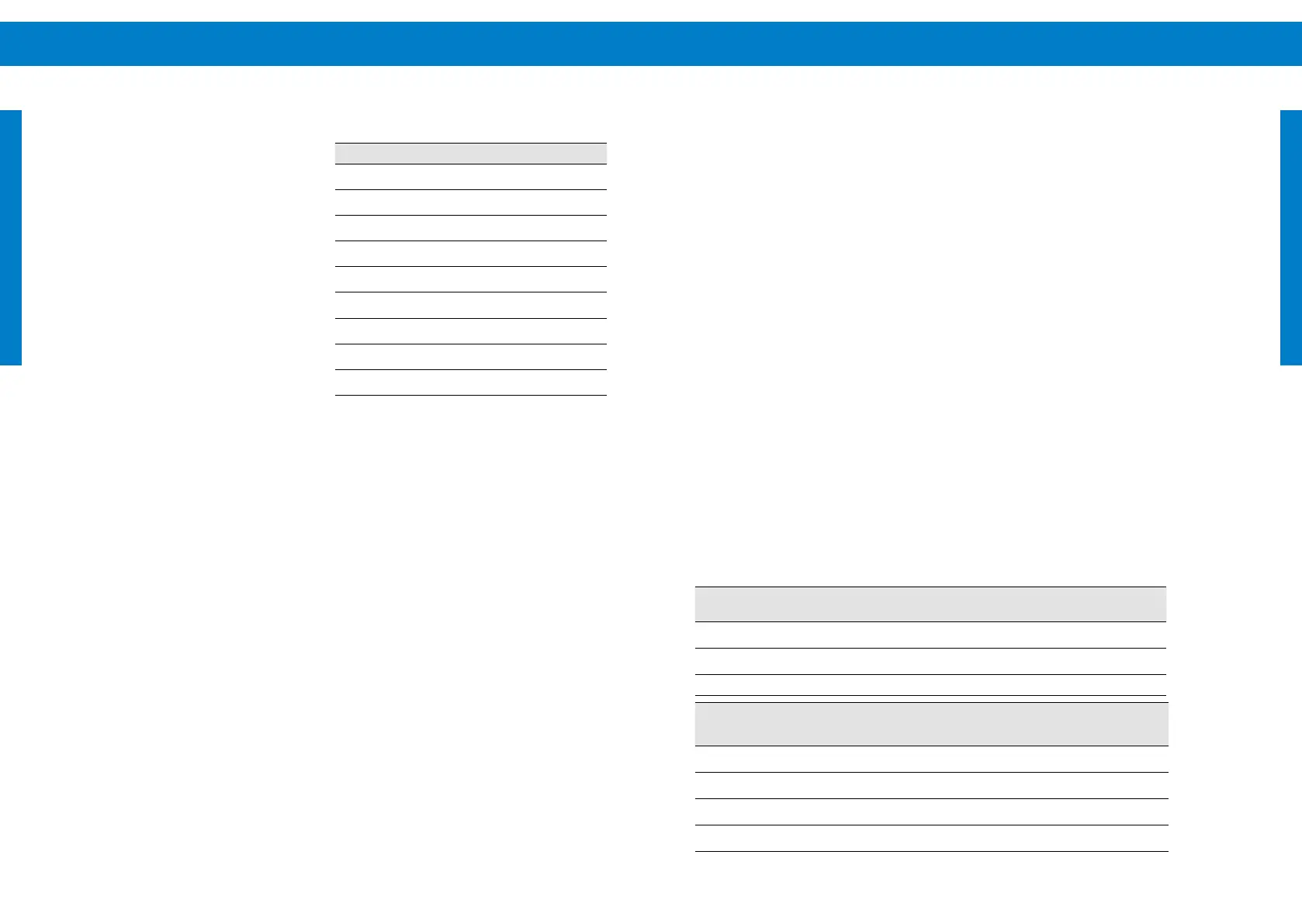

Table 14: Motor cable resistances for surface pump motors

Surface pump CS-F motors PSk3 system

Phase-to-phase resistance

[Ω]

AC DRIVE CS-F 5.5 kW PSk3-7 1.4

AC DRIVE CS-F 7.5 kW PSk3-9 1.4

AC DRIVE CS-F 11 kW PSk3-15 0.8

Surface Pump CS-G Motors PSk3 system

Phase-to-phase resistance

[Ω]

AC DRIVE CS-G 5.5 kW PSk3-7 1.7

AC DRIVE CS-G 7.5 kW PSk3-9 1.3

AC DRIVE CS-G 11 kW PSk3-15 0.8

AC DRIVE CS-G 11 kW/4p PSk3-15 0.8

Insulation resistance

Use a megohmmeter at 500 –1,000 V.

Measure each phase to ground. Connect one test

prod to the phase hold the other test prod to the

pipe work, or if plastic pipes are used to the ground

wire.

If the insulation resistance is below 0.5 MΩ, the

motor cable must be checked for damage.

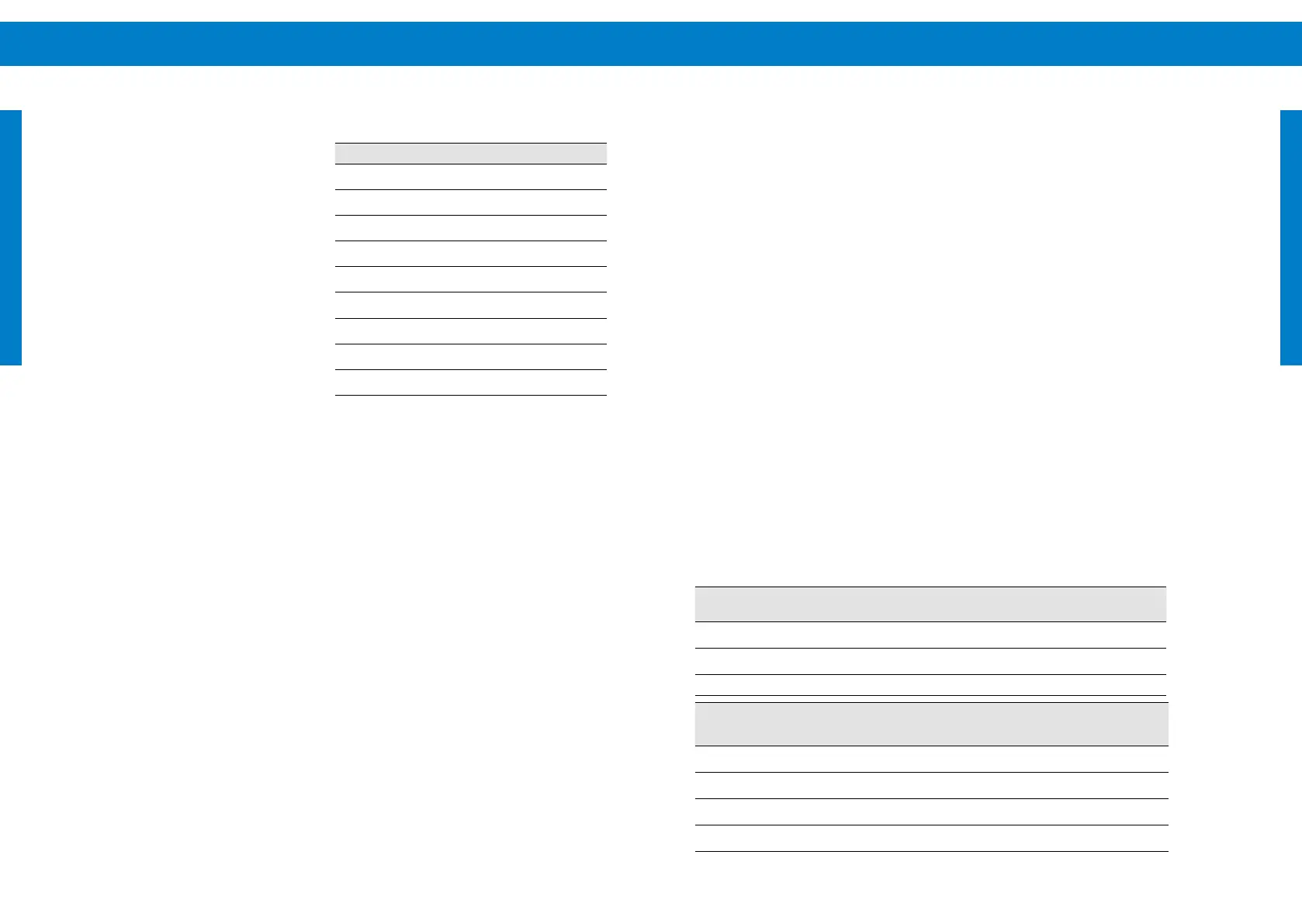

Table 13: Motor cable resistance

Cable Resistance [Ω / 100 m]

4 mm2 / AWG 11 0.40

6 mm2 / AWG 9 0.25

10 mm2 / AWG 7 0.17

16 mm2 / AWG 5 0.10

25 mm2 / 4 AWG 0.066

35 mm2 / 2 AWG 0.047

50 mm2 / 1 AWG 0.033

70 mm2 / 2/0 AWG 0.023

95 mm2 / 3/0 AWG 0.018

To measure the winding and insulation resistance

disconnect all motor leads from the controller. A

good quality multimeter is necessary to measure the

phase-to-phase resistance with an accuracy to the

rst decimal place. (“0.1 Ohms”). It is also advisable

to consider the resistance of the multimeter leads

when measuring very low values:

Hold the tips of the multimeter together and note

the value.Always substract this value from your

motor resistance measurements!

Winding resistance

(1) Set the multimeter to “resistance measurement”

and select the lowest measuring range.

(2) All PSk3 motors are 3-phase motors. Measure

the resistance of phase-to-phase: 1-2, 2-3, 3-1.

Make sure there is good contact between the

probes and the cable.

(3) The deviation between the phases should be

within 10 %. If the deviation is too high, the

reason is likely a damaged submersible cable or

a faulty cable splice.

(4) The absolute value is made up of the resistance

of the motor winding and the submersible

cable. The resistance of the submersible cable

depends on its length and size. For copper

cable, the values of the table "Table 13: Motor

cable resistance" and "Table 14: Motor cable

resistances for surface pump motors" on page

67, can be used as a rough approximation.

Loading...

Loading...