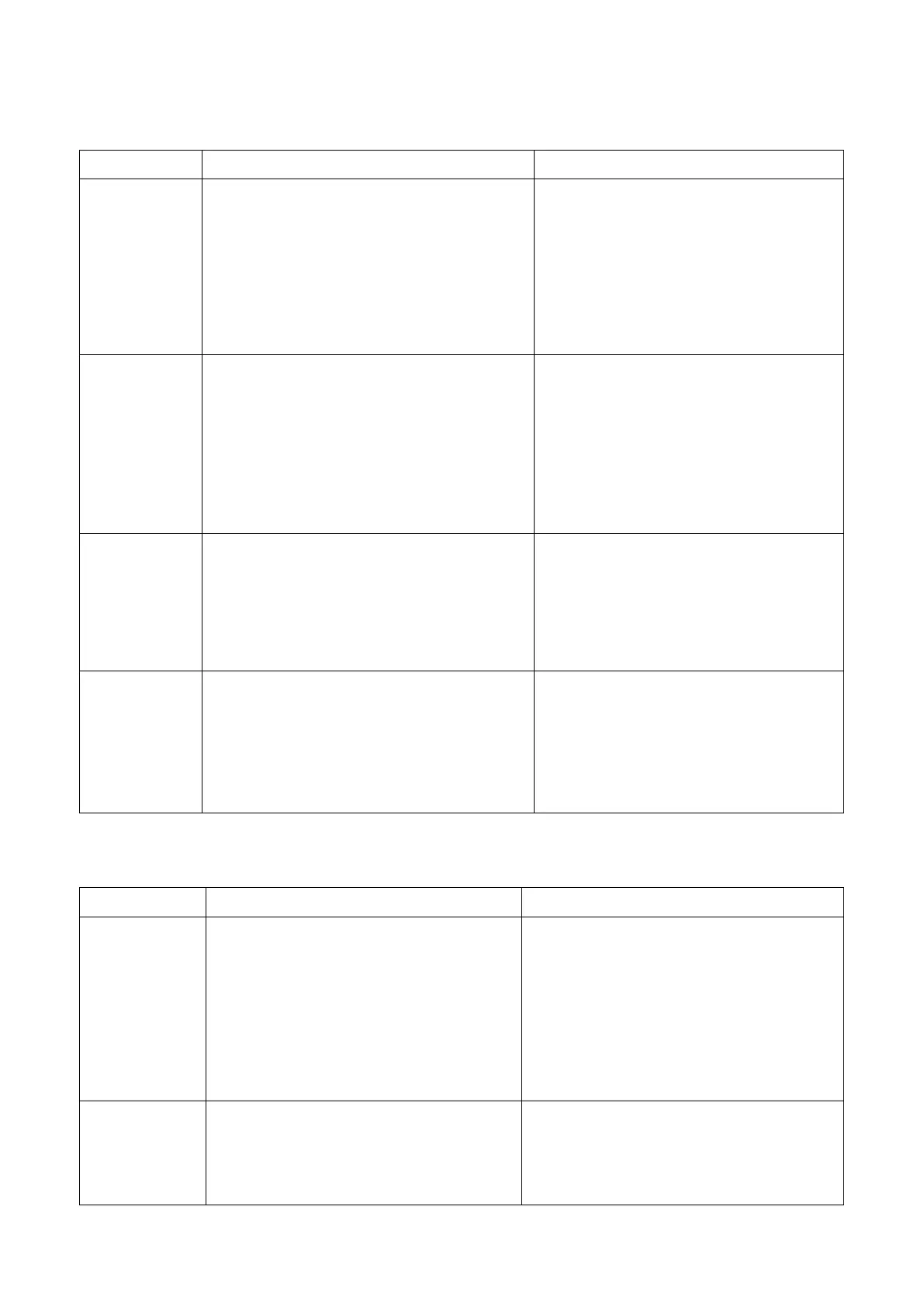

3.16.1.2 Gearbox failure and troubleshooting

Table 3-4 Gearbox failure and troubleshooting

Failure Cause Troubleshooting

1. Gear

engagement is

difficult, or

failure

(1) Clutch is not thoroughly released.

(2) Interlock link is too long

(3)

Shift block of gear lever seriously wears

out.

(4)

Engaging sleeve end face and gear end

face are worn out or damaged.

(1)

Troubleshoot it according related

means

(2)

Interlock link should be properly

shortened.

(3) Replace gear lever

(4) Repair of replace it

2.Auto gear

disengaging

(1) Interlock link is too short.

(2) Shift fork shaft groove seriously wear out.

(3)

Spring pressure of interlock pin is

insufficient.

(4)

The bearing on the gear shaft is worn out

to have the shaft inclined.

(5) Gear block spline wears out.

(1)

Interlock link should be properly

extended.

(2) Replace shift fork shaft

(3) Adjust or replace interlock pin spring.

(4) Replace bearing.

(5) Replace gear block

3. Disorder gear

engagement

(1) Gear lever knob seriously wears out.

(2)

Gear shifting guide plate groove seriously

wears out.

(3)

Shift fork and shift groove of meshing

sleeve wears out.

(4) Serious worn gear or spline.

(1) Replace or repair gear lever

(2) Replace gear shifting guide plate.

(3) Replace shift fork and meshing sleeve.

(4) Change the worn parts

4. There is

noise or knock

in gearbox.

(1)

Gear excessively wears out, tooth face is

peeling off or breakage.

(2) Bearing seriously wears out or is damaged.

(3)

Lubricant is insufficient or the lubricant

quality does not satisfy the regulation.

(4) Shaft spline and gear spline hole are worn.

(1) Replace gear

(2) Replace bearing.

(3) Change lubricant or fill it up.

(4) Change the worn parts

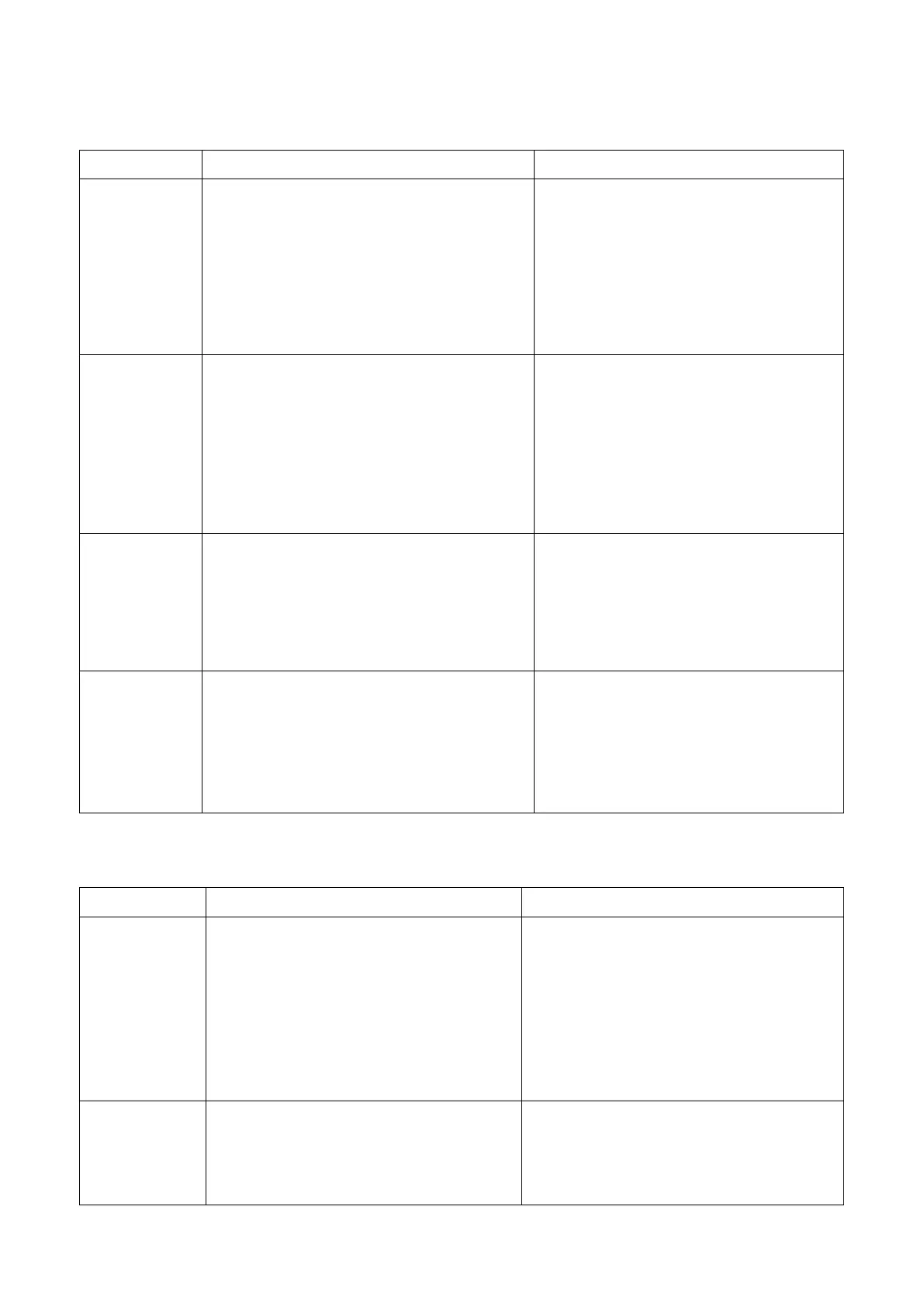

3.16.1.3 Rear axle or brake failure and troubleshooting

Table 3-5 Rear axle or brake failure and troubleshooting

Failure Cause Troubleshooting

noise.

(1) Bevel pinion bearing play is excessive.

(2) Gear engagement is abnormal.

(3) Bevel gear pair bearing or gear is

damaged.

(4) Differential bearing is worn out or stuck.

(5) Planet gear or shim is worn out.

(6) Differential bearing is worn out or

damaged.

(1) Readjust to specification

(2) Readjust to specification

(3) Replace bearing or gear

(4) Replace differential shaft

(5) Replace planet gear or shim.

(6) Replace differential shaft

2. Bevel pinion

bearing and

differential

hot.

(1) Preload is excessive.

(2) Lubricating is poor

(3) Bevel gearset pair play is too narrow.

(1) Readjust the bearing preload.

(2) Check the lubricant level, and add it if

necessary.

(3) Readjust the gear backlash.

Loading...

Loading...