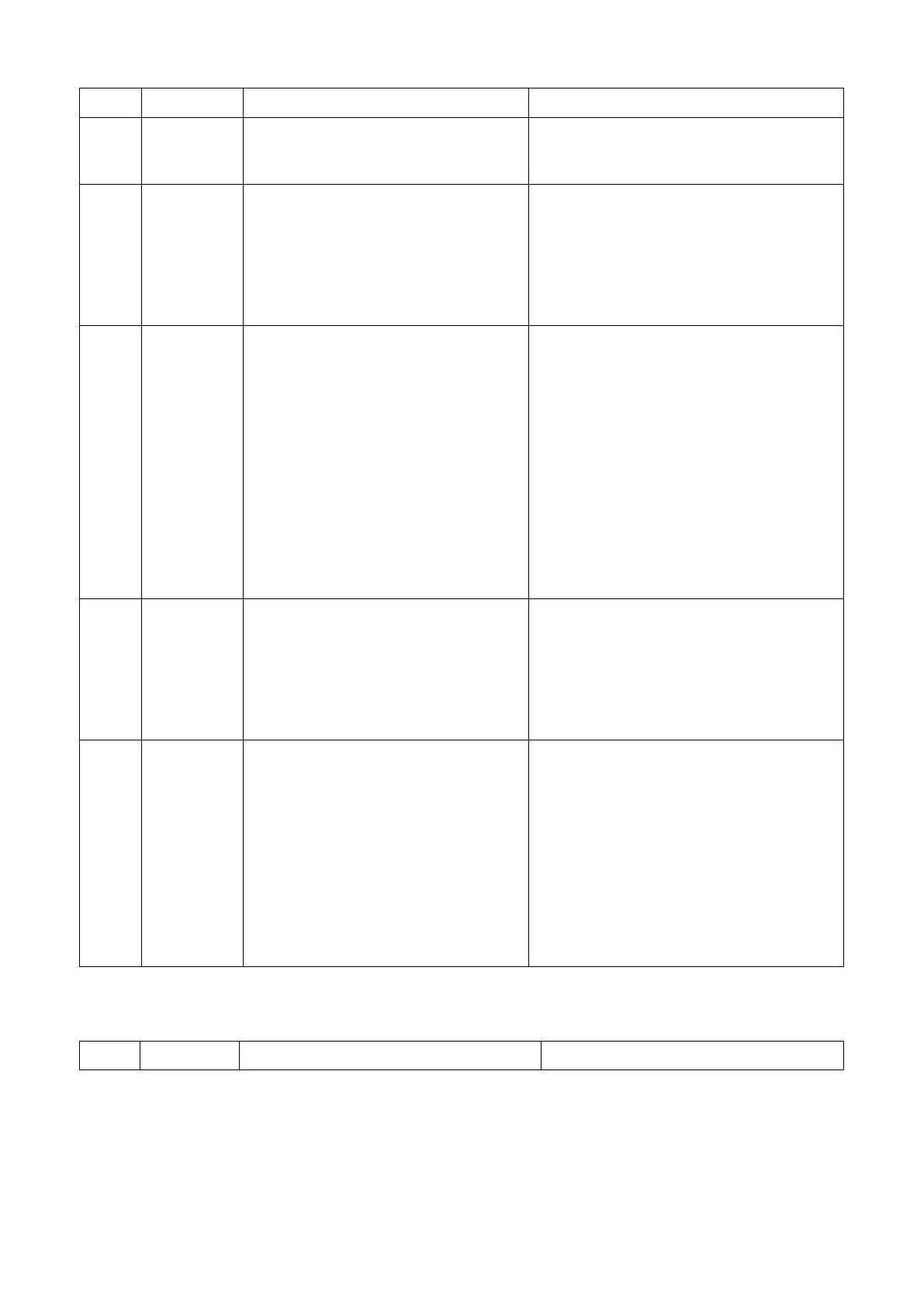

Index: Failure Cause Troubleshooting

causing insufficient pressure.

(5)

There is oil leakage from the

cylinder sealing ring.

(5) Replace cylinder sealing ring

3

The

agricultural

implement is

joggling

during

lifting at

slow speed.

(1) The oil filter is clogged.

(2)

There is air in the oil absorption

pipeline.

(3) Gear pump is invalid.

(4) The hydraulic oil level is too low.

(1) Replace or clean filter element

(2)

Troubleshoot the leakage at the

connector and O-ring.

(3) Replace gear pump

(4) Fill lubricant to specification.

4

After lifting

the

agricultural

implement,

it frequently

“Nods”.

Descent

speed only

under

self-weight

condition is

fast after the

engine

flameout.

(1) Distributor one-way valve sealing is

poor.

(2) The lowering valve sealing is poor.

(3) Cylinder relief valve is leaking oil

or improperly adjusted.

(4)

There is oil leakage from the

cylinder piston O- ring.

(5)

The sealing ring between the

distributor or cylinder head and oil

inlet of lifter housing is not well

installed or damaged.

(1) Clean the one-way valve and face it up

if necessary.

(2) Clean or face up the descent valve

(3) Adjust or readjust cylinder relief valve.

(4) Replace O-ring.

(5) Check and replace sealing ring

5

With the

handle at the

lifting

position, the

distributor

gives sharp

sound.

(1)

The adjustment is not correct,

causing the inner lifting arm against

lifting housing to have the relief

valve opened.

(1)

Firstly measure the lifting height of

agricultural implement, then readjust the

force/position adjusting lever to let

lifting extreme position is lower than

original position.

6

There is no

hydraulic

output at the

cylinder

head or the

hydraulic

output is

powerless.

(1) The inlet pipe to cylinder is not cut

off.

(2)

The sealing between front taper

body of the descent speed control

valve and taper hole is poor.

(3) The lifter is at neutral position

(1) Clockwise tighten the descending speed

control hand wheel.

(2) Repair and face up the sealing between

the front taper body of descending speed

control valve and taper hole. Or replace

the descend speed control valve.

(3) Push lifter control handle to “Lowering”

position in order to lower outer lift arm

to the lowest position and cut off inlet

oil line of oil tank. Then push control

handle to “Lifting” position.

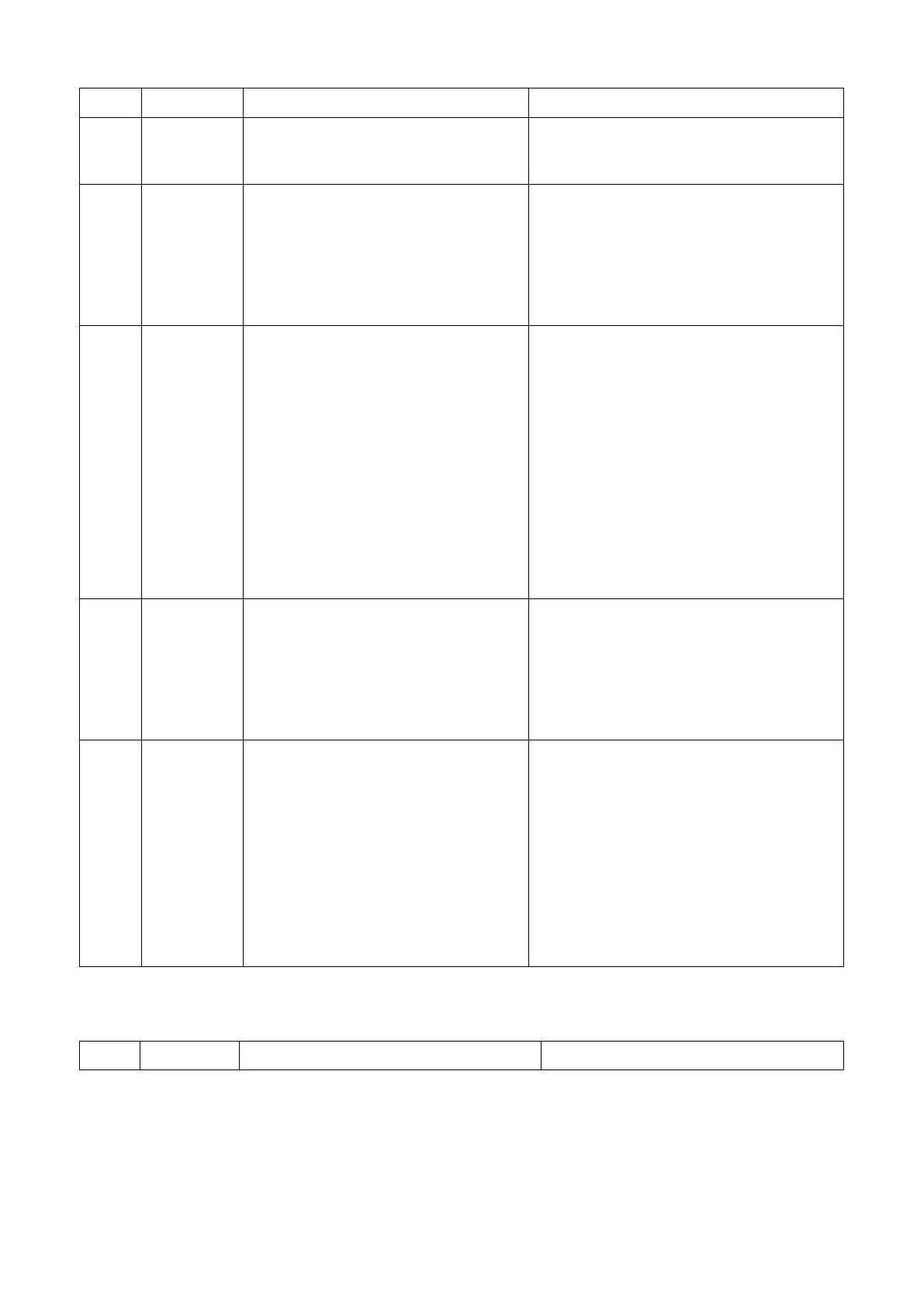

3.16.1.7 Air brake system failure and troubleshooting

Table 3-9 Air brake system failure and troubleshooting

Index: Failure Cause Troubleshooting

Loading...

Loading...