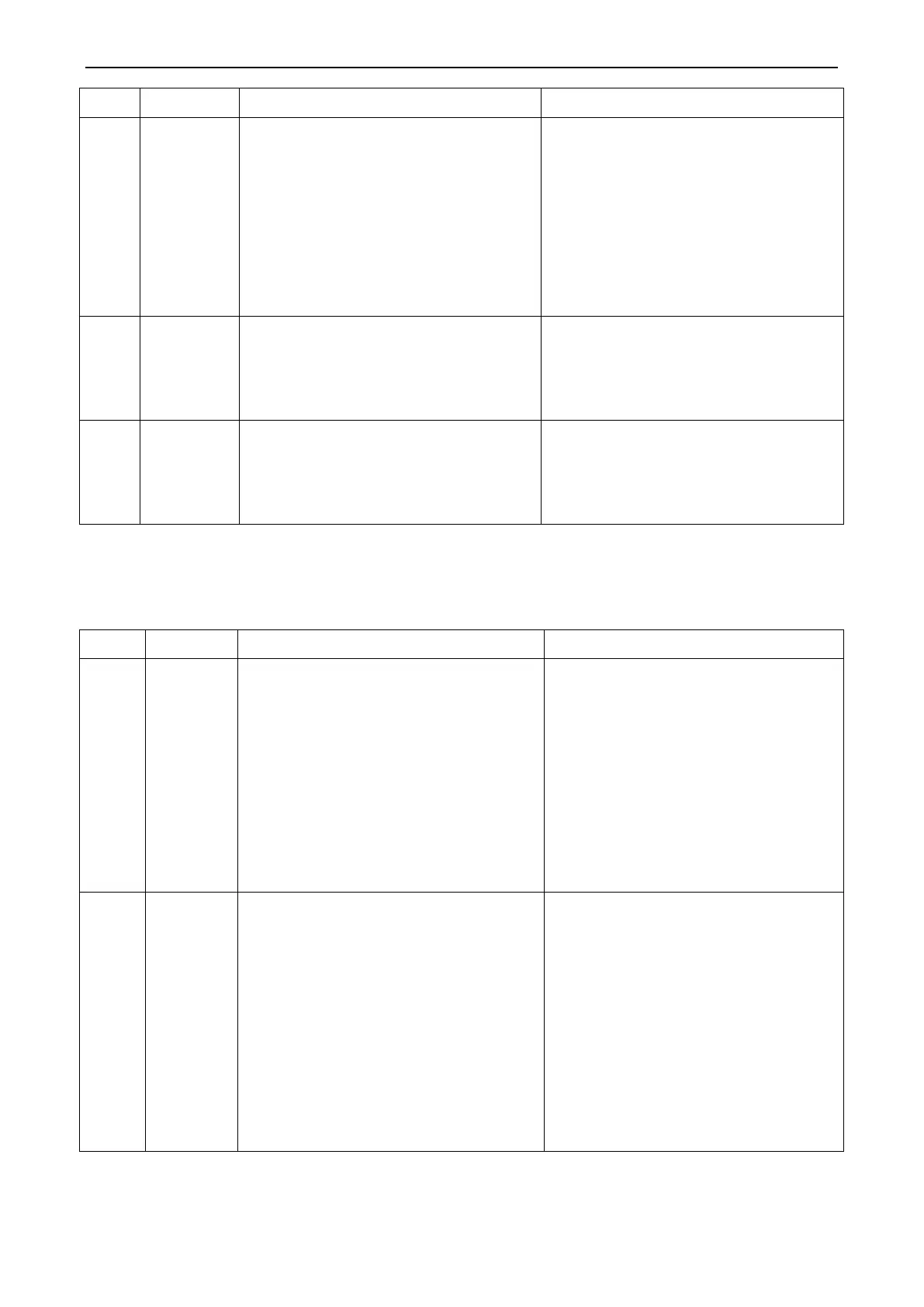

Operation Instruction

Index: Failure Cause Troubleshooting

1

Air pressure

is

insufficient.

(1) Air is leaking out of pipe.

(2) Exhaust valve plate of air pump wears

out or the spring is damaged.

(3) Air pump piston ring or cylinder liner

severely wears out.

(4) Air pressure alarm is fault.

(5)

Relief valve could not be tightly

closed.

(1) Check and troubleshoot the air leaking

points.

(2) Replace it

(3) Replace piston ring and cylinder liner.

(4) Replace or repair air pressure alarm.

(5) Check or replace relief valve.

2

The air

cut-off

brake valve

does not

reset

(1) The dust enters the air cut-

valve

(2) The oil or water enters the air cut-off

brake valve

(1) Clean the air cut-off brake valve

(2) Drain the oil or water in air reservoir.

Clean air cut-off brake valve.

3

The air

cut-off

brake valve

does not

exhaust

(1) Tappet is stuck.

(2)

Return spring is broke or its elastic

force is weakened.

(1)

Repair it to make tappet movement

flexible without stuck.

(2) Replace return spring

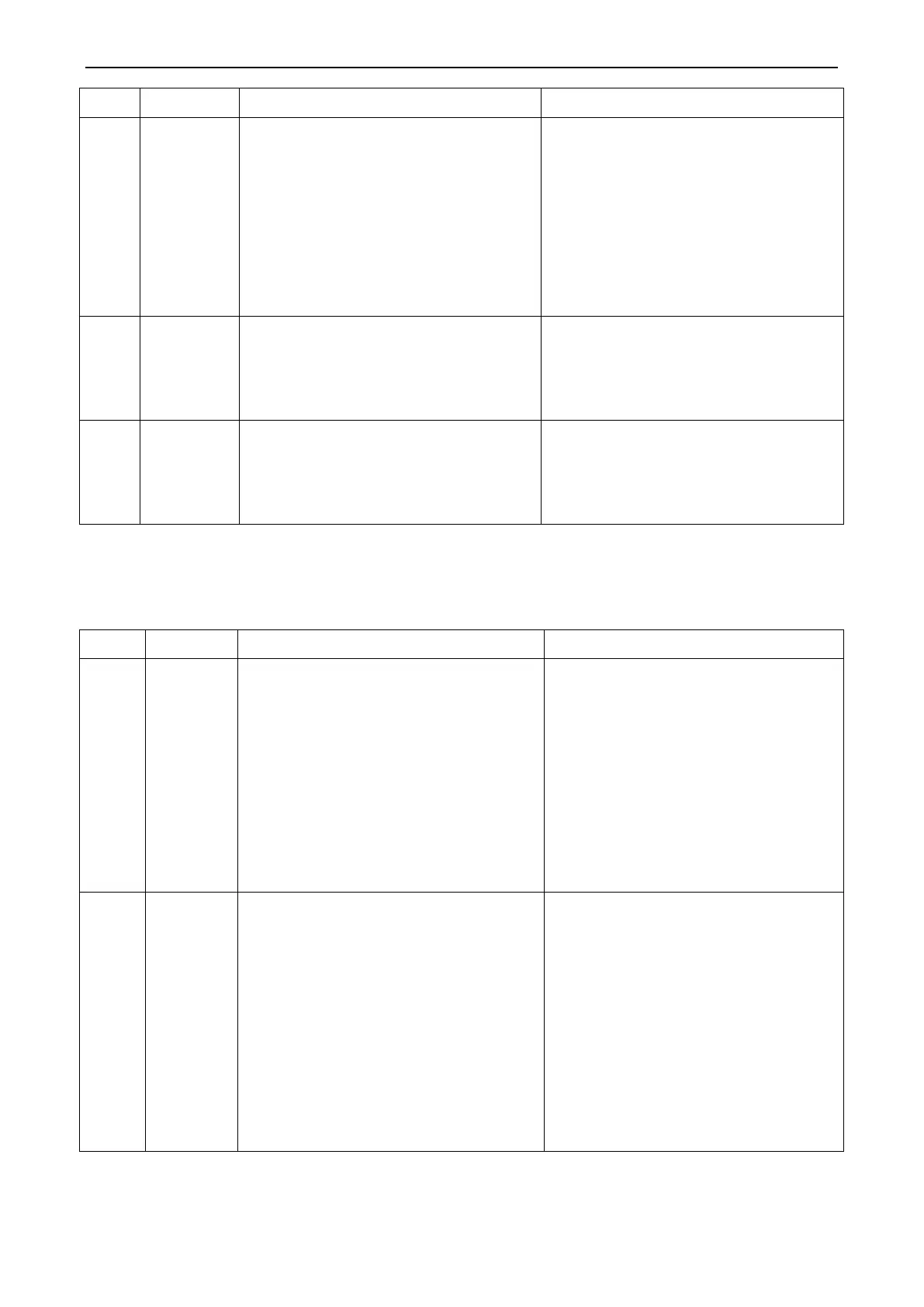

3.16.2 Electrical system failure and troubleshooting

3.16.2.1 Starter motor failure and troubleshooting

Table 3-10 Generator failure and troubleshooting

Index: Failure Cause Troubleshooting

1.

Generator

rotate.

(1) Battery power is insufficient.

(2) Dirty battery plate or loose cables.

(3)

Cable joint is loose or ground wire is

rusted.

(4)

The control circuit such as starting

switch etc is disconnected.

(5) The carbon and commun

well-connected.

(6)

Starter motor circuit is open, short

circuit.

(1) Charge the battery as specified.

(2) Clean dirt and tighten connections.

(3)

Tighten the connection and remove

the corrosion.

(4) Check the circuit for reliability.

(5)

Adjust the spring pressure of carbon

brush and clean the communtator.

(6) Repair starter motor

2

Starter

motor

powerless

or can not

engine.

(1) Battery power is insufficient.

(2) Cable is not will connected.

(3)

Communtator surface is burned or

contaminated with oil.

(4)

The carbon brush excessively wears

out or the spring pressure of carbon

brush is insufficient, causing it poor

connection with communtator.

(5) Main contact point of solenoid valve is

burnout and not well connected.

(6)

Bearing is severely worn out, the

armature is against its housing.

(1) Charge the battery as specified.

(2) Tighten the wire connection

(3)

Smooth the communtator surface to

clean oil contamination.

(4) Replace or adjust it

(5) Polish it with “0” nonmetal abrasive

paper

(6) Replace bearing.

13

Loading...

Loading...