Use the following procedure to use the machine

for drilling:

1. Clamp the workpiece or secure it against

moving.

➢ Use the anti-slip mats provided for this

purpose.

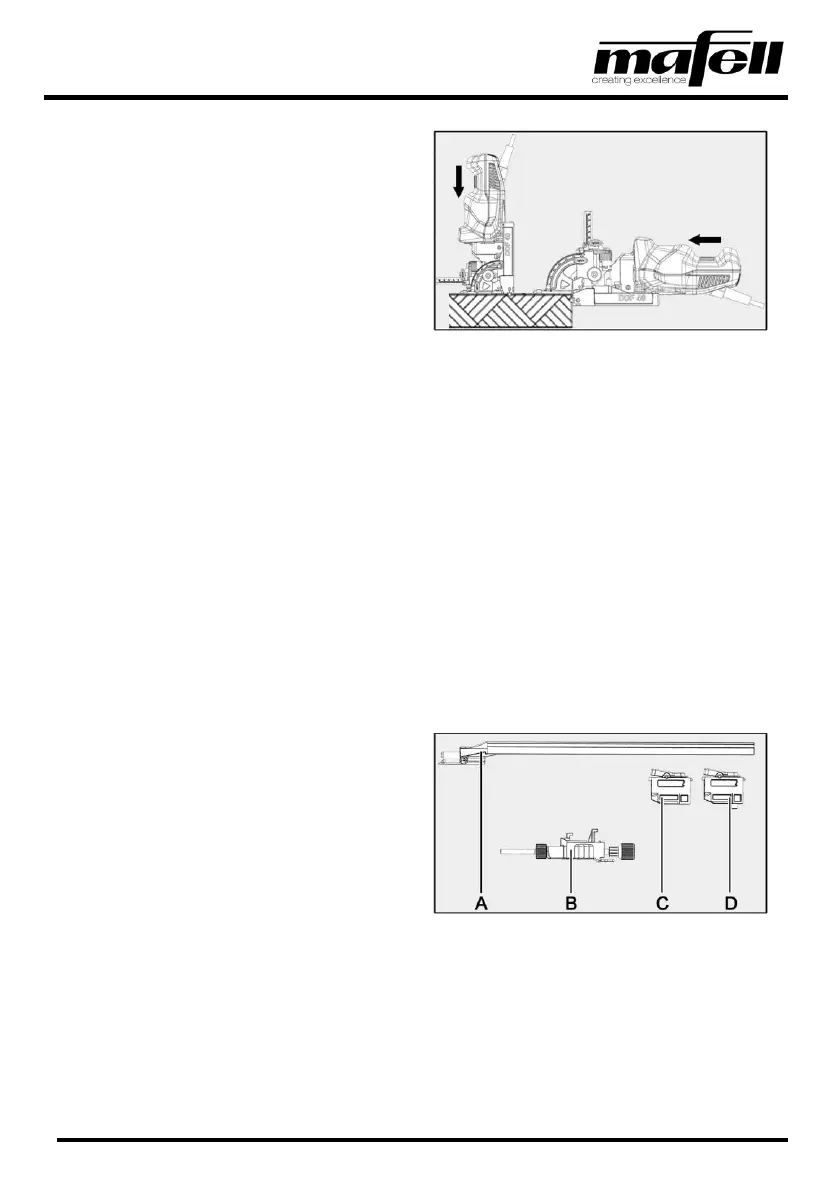

2. Position the machine horizontally or vertically on

the workpiece, as required.

3. Using the spring-loaded stop pins or the

accessories described below, bring the machine

in contact with the outer edges of the workpiece.

➢ Ensure that the contact surfaces of

machine and workpiece are precisely

aligned with each other.

4. Switch on the machine.

5. Push the motor unit forward until it hits the stop.

During this process, hold the machine by the

recessed grips or the rear housing section.

➢ The motor unit moves automatically back

to the home position.

6. Switch off the machine.

✓ Drilling was performed.

5.4 Drilling with accessories

5.4.1 Drilling with lateral guide fence set

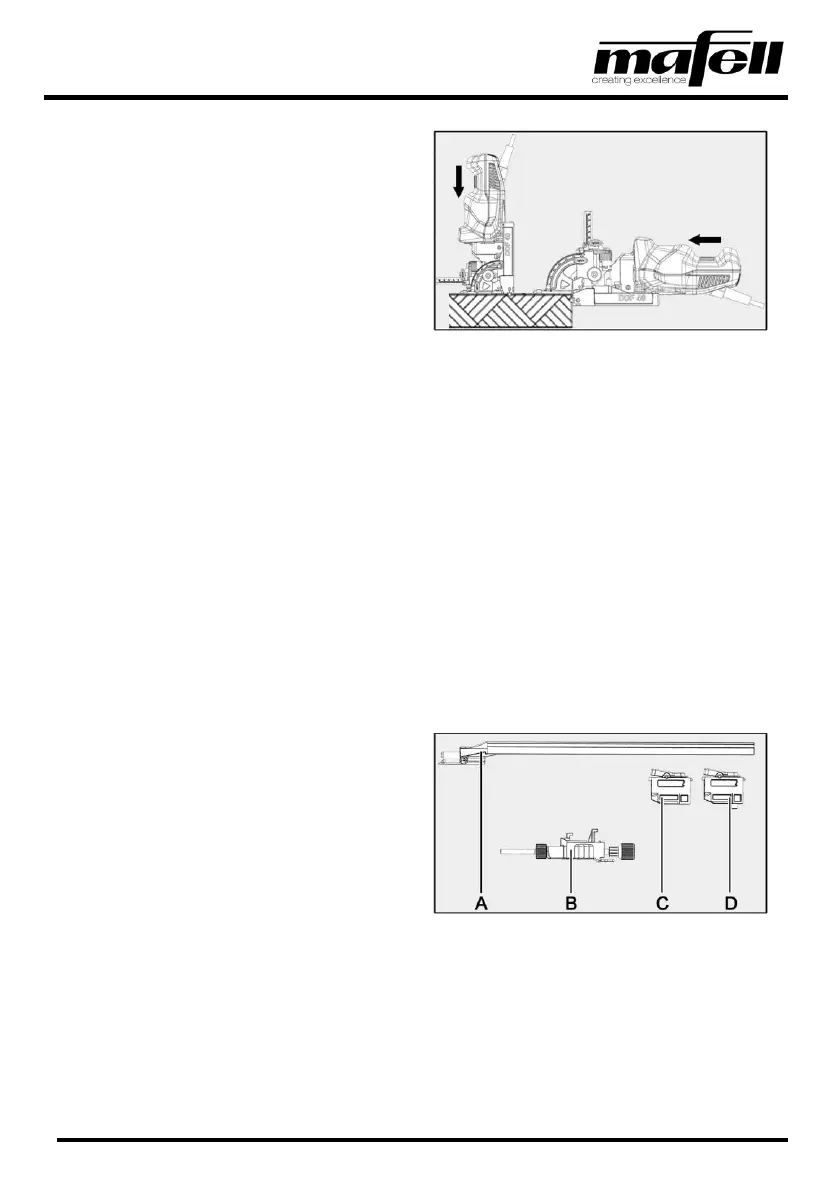

The lateral guide fence is suitable for large distances from the edge in carcass processing.

The lateral guide fence consists of 4 parts

- Lateral guide fence (A)

- Roller edge guide (B): For offset carcass

processing with continuous fine adjustment

- Rider (C): To accommodate the roller edge guide

or for ancillary guide fences

- Rider with resilient stop pin (D): To adjust different

edge distances

The lateral guide fence can be inserted on alternate

sides of the base plate.

Loading...

Loading...