6 Service and maintenance

MAFELL machines are of a low-maintenance design.

The installed ball bearings are lubricated for life. After a longer period of operation, MAFELL recommends that

the machine be handed over to an authorized MAFELL service workshop for inspection.

6.1 Storage

Clean the machine thoroughly if you will not use it for quite some time. Spray bare metal parts with a rust

inhibitor.

7 Troubleshooting

Risk of injury from a sudden start of the machine.

There is a risk that the machine starts suddenly due to carelessness when

working with the machine or during troubleshooting. The rotating tool can cause

serious injuries.

➢ Determining the causes of existing malfunctions and their elimination

always require increased attention and caution!

➢ Pull out the mains plug before you start troubleshooting!

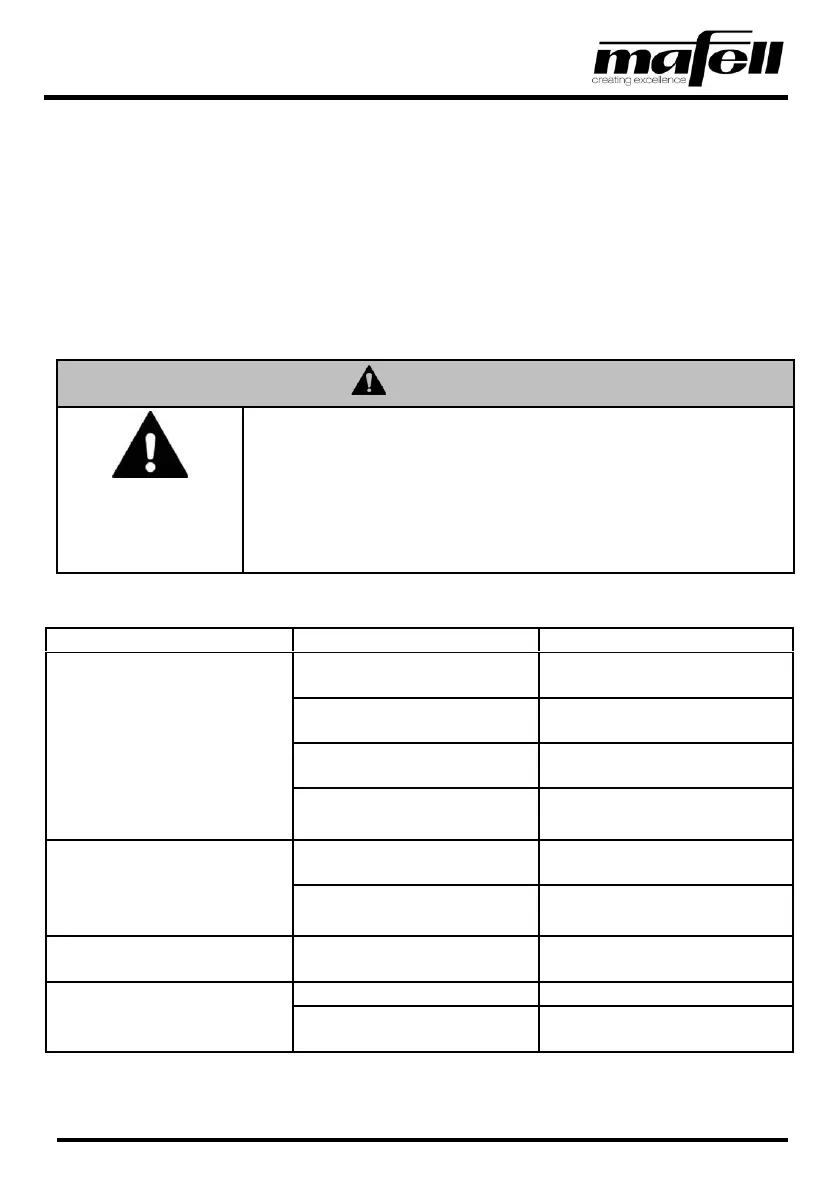

Some of the most common malfunctions and their causes are listed below. For other malfunctions, please

contact your dealer or MAFELL Customer Service directly.

Machine can not be switched on

Mains voltage missing or too low

Have the power supply checked by

an electrician

Have the fuse replaced by an

electrician

Take the machine to the MAFELL

customer service workshop

Rotary button is at "Tool change"

Set the rotating rotary button to

drilling depth "1" or "2"

Machine stops during the drilling

process

Have the mains back-up fuses

checked by an electrician

Take the machine to the MAFELL

customer service workshop

Burn marks at the boreholes

Drill bit blunt or unsuitable for the

operation

Sharpen or replace the drill bit

Long cutting operation without

extraction

Connect the machine to an

external extraction

Loading...

Loading...