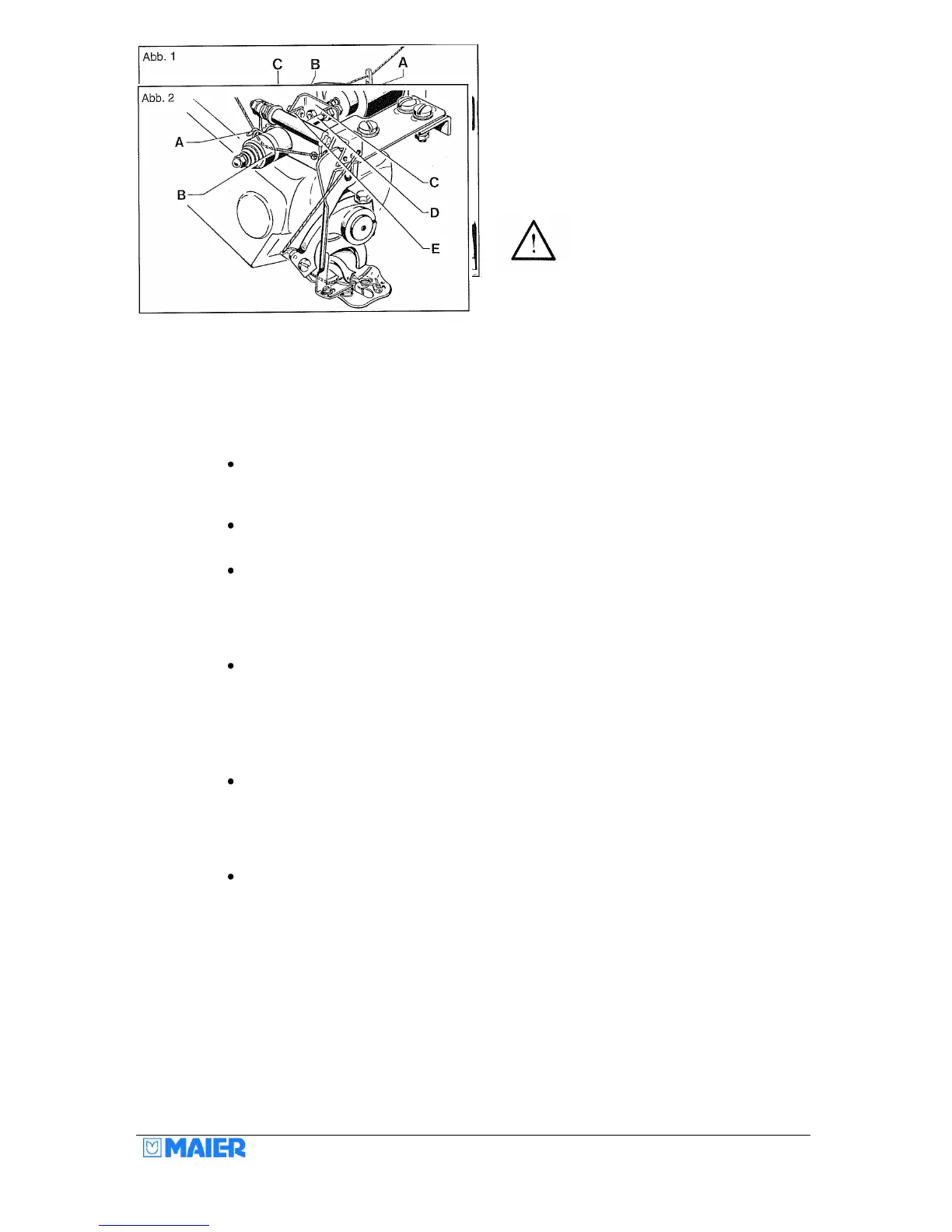

Machine without thread cutter (Fig. 1)

The thread is run over the thread stand through the thread guide A, the rear thread

eyelet, between the thread tensioning discs C (not round the pin), through the front

thread eyelets D (right-hand hole) and through the hole on the needle claw E.

The needle is threaded upwards from below. Move the needle lever to the extreme

left position for threading.

The thread eyelet D offers three possibilities for threading. In conjunction with the

thread take-up cam, the tension of the sewn thread loop can be influenced in this

way. Normally the thread is run through the right-hand hole. However, running the

thread through the left-hand hole gives a slacker thread loop. The effect can be

increased further by turning the thread take-up cam (set collar).

Adjust the thread tension C as slack as possible. Excessive thread tension can cause

marks (thread pulls) on the outside of the material. Please use the correct thread

quality e.g. 120/single, 120/double, 200/double.

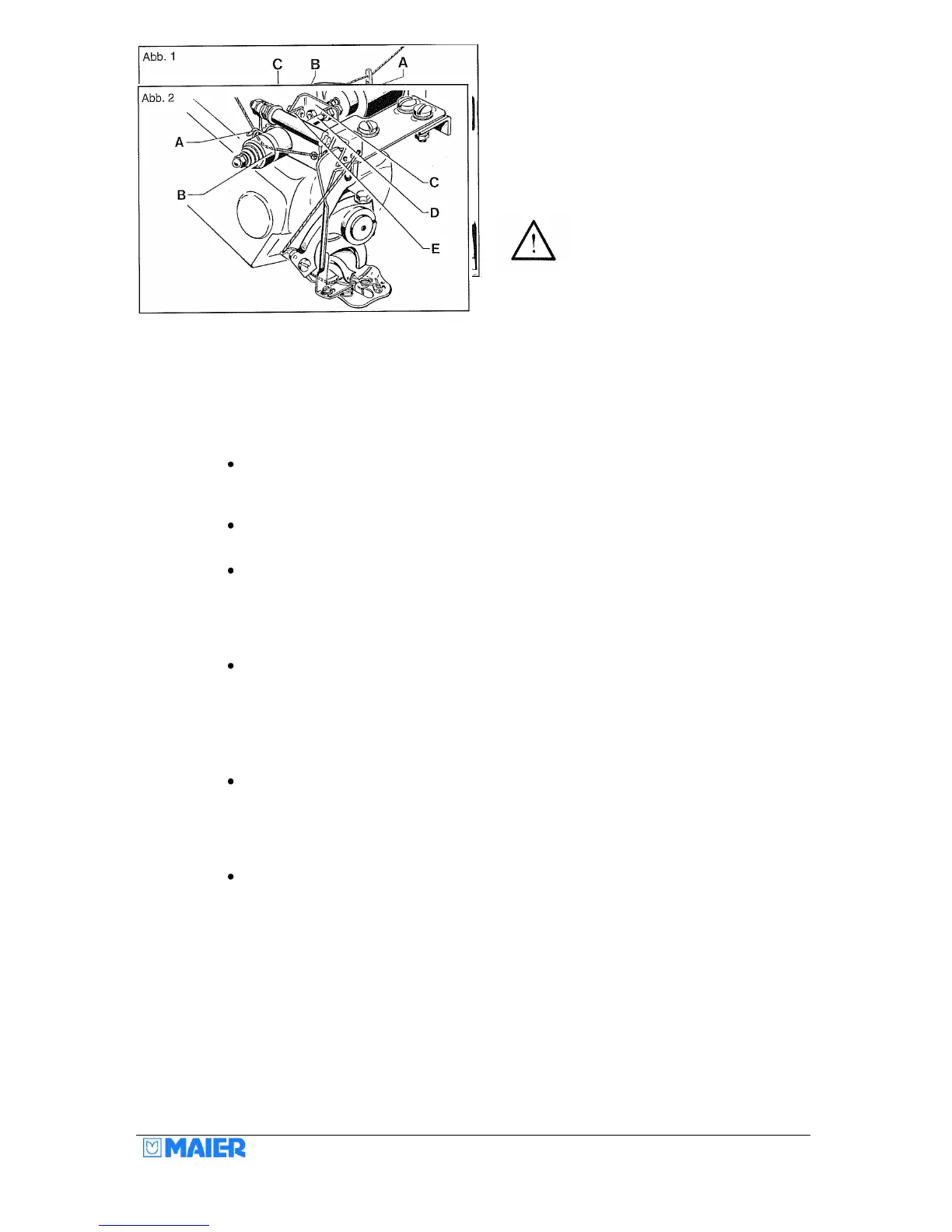

Machine with thread cutter (Fig. 2)

When using our thread cutter (Fig. 2), the machine is threaded in the same way as

shown in Fig. 1. In addition, however, the thread is also run through eyelet A and the

groove of the thread clamp B, through the hole in the base plate to the front thread

eyelet. Push back the flexible cap B to do this. As a result, the thread is clamped

during the cutting operation.

There must be approx. 0.2 mm play between the nuts and the angle flange, so that

the connection pin D together with the brake cap B can be turned or moved easily.

Also, connecting rod E must not bind.

Loading...

Loading...