Basically, the following rule must be borne in mind:

When adjusting the eccentric cam G (Fig. 18), the looper is raised or lowered at both

points E and L. By turning looper holder B, the path of the looper is raised on one

side and lowered on the other.

Adjusting the height of the looper

If the long finger of the looper touches the needle at point L or the stitch plate at point

E or D, the looper must be set slightly higher. To do this, slacken the two locking

screws F (Fig. 18) on the eccentric cam G. If the looper touches the needle, turn the

eccentric cam G upwards in a clockwise direction. If the looper is too far away from

the needle, adjust the eccentric cam anticlockwise.

If, on the other hand, the looper touches the stitch plate at point E or D, and at the

other side the needle touches the short finger of the looper at point L, then an

adjustment of the eccentric cam G is not sufficient. This fault can only be rectified by

turning the looper holder B slightly. To do this, slacken screws H and then retighten

them afterwards. This will prevent any contact by the small looper finger at point L

and will raise the looper at points E and D, so that it no longer touches there.

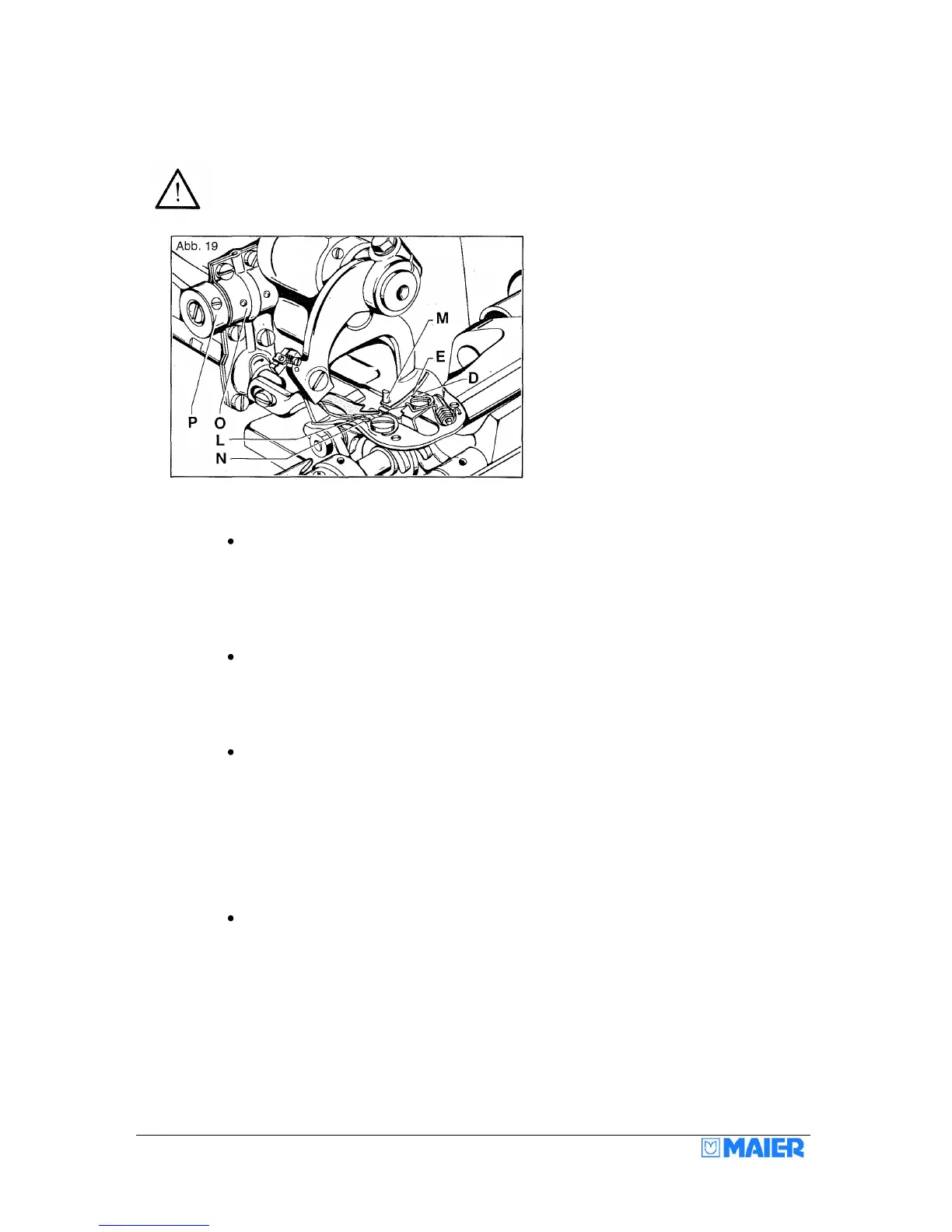

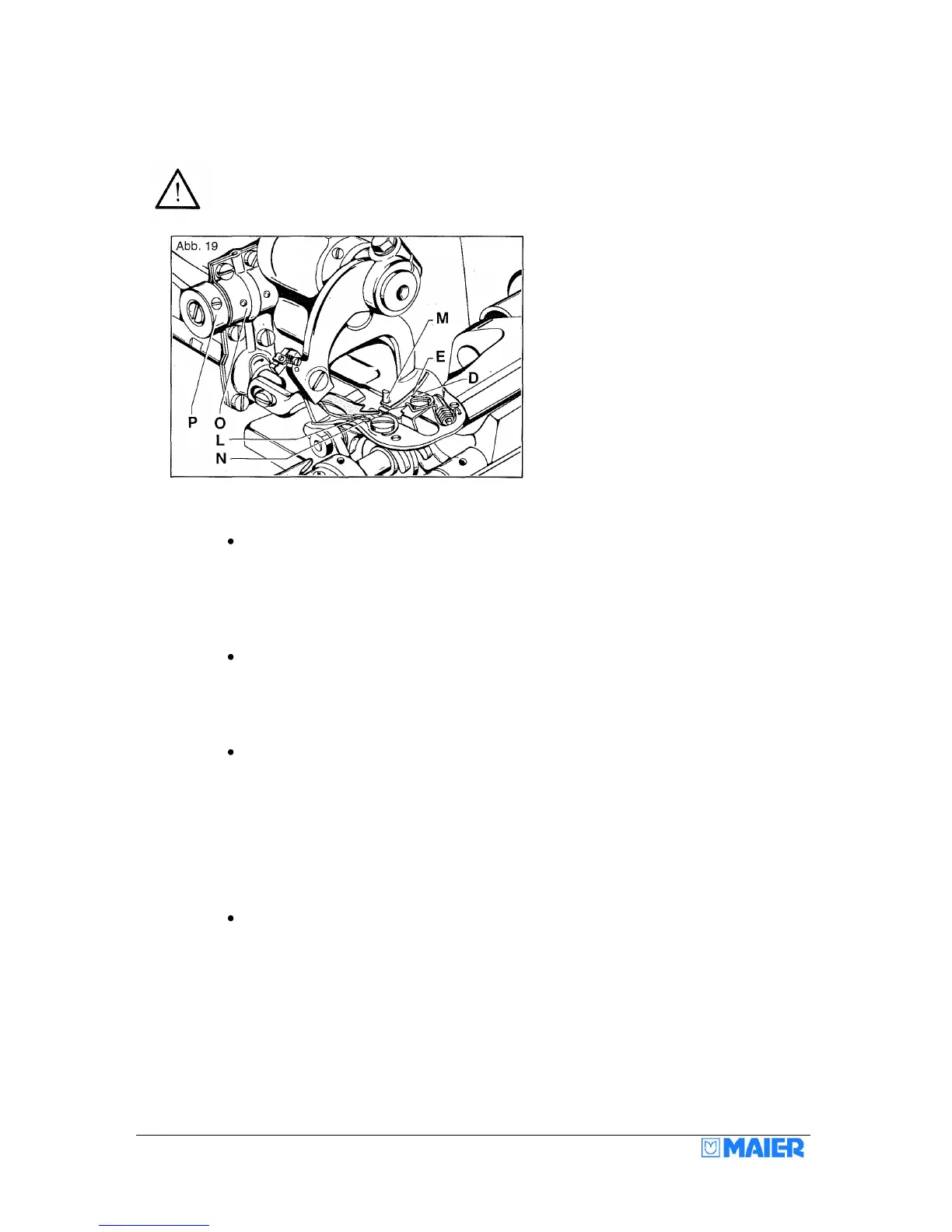

Adjusting the lateral position of the looper

If the small finger of the looper hits pin M or hits the stitch plate at point N, check first

whether the feed dog lever link O is firmly tightened on to the set collar P, so that the

feed dog lever link has no play. Adjust the set collar if necessary. If the looper still hits

at points M or N, it can be adjusted to the left or right if required, by slackening

screws F and moving the entire eccentric cam G to the right or to the left.

Loading...

Loading...