GROVE Published 10-21-2010, Control# 198-04 6-25

5540F/YB5515 SERVICE MANUAL ENGINE AND ENGINE SYSTEMS

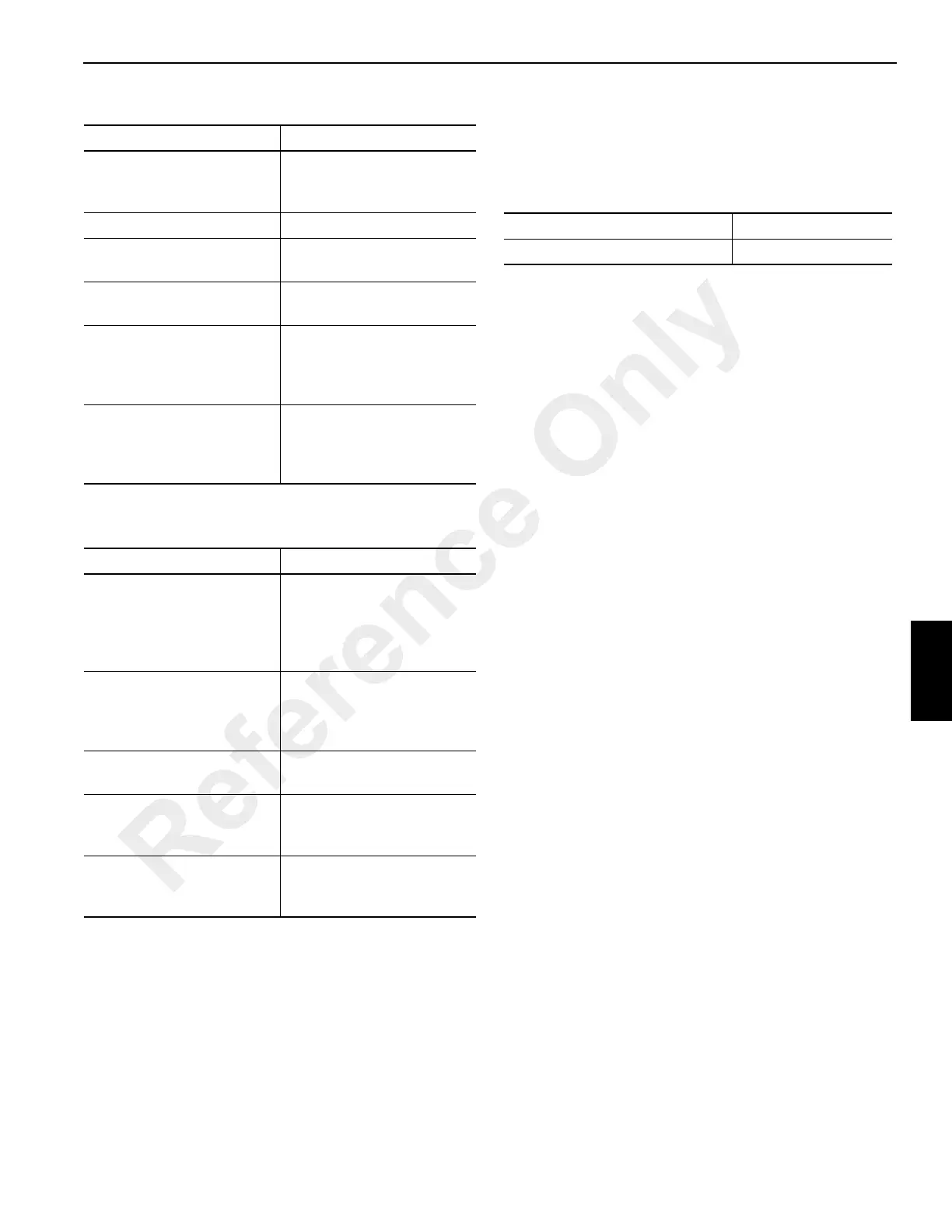

CONDITION: Engine runs too rich on LPG

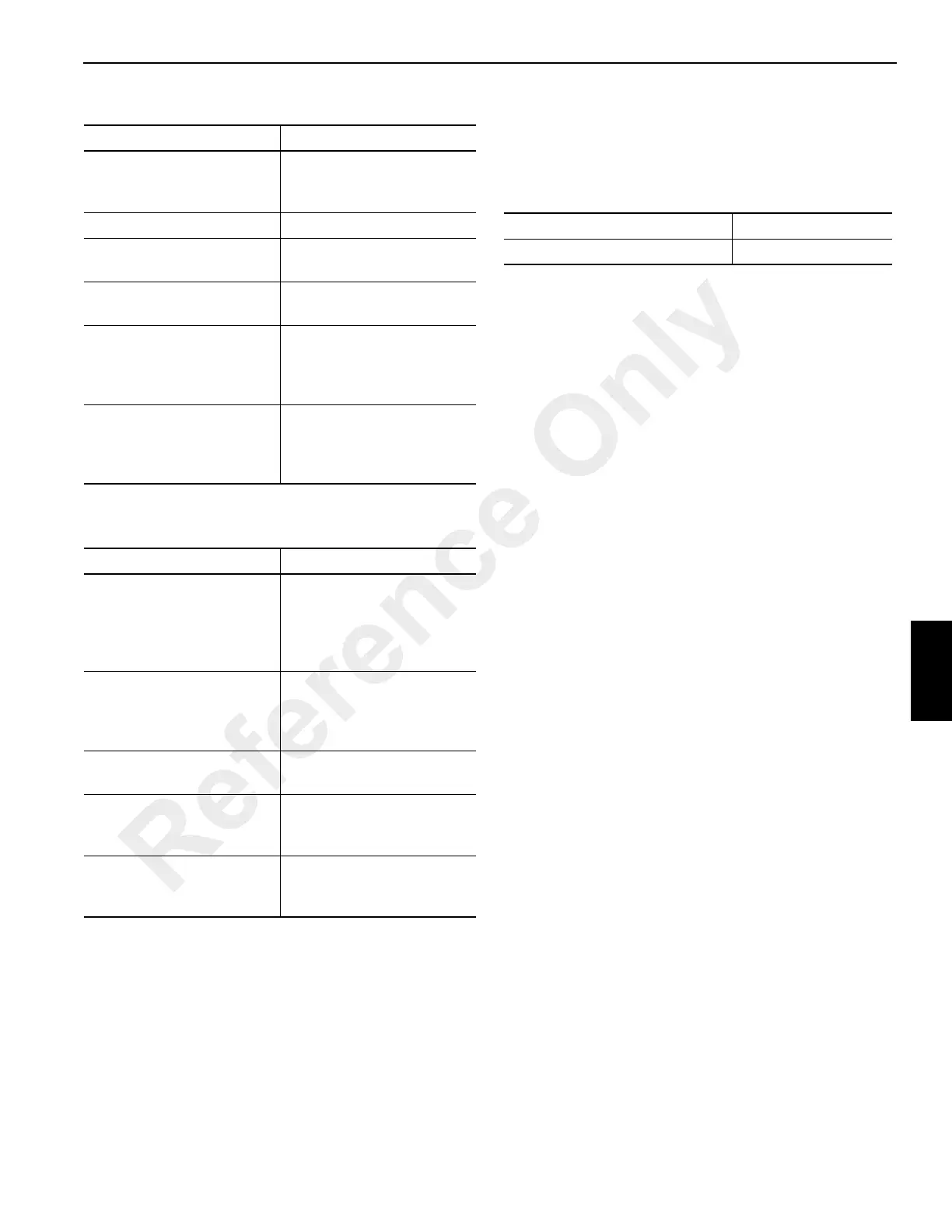

CONDITION: Engine will not start on LPG

Checks and Adjustments

Spark Plug Gap

Check, clean and adjust the spark plugs every 3 months, or

after every 500 hours of operation, whichever occurs first, or

more often if required.

Thoroughly, clean the spark plugs, including the threads.

Check the electrode gap with a feeler gauge. There will be a

small amount of friction as you move the feeler gauge

between the electrodes, if adjusted correctly. Bend only the

side of the electrode to set the gap.

Engine Timing

The engine timing should be checked and set as follows:

1. Connect the timing light to the No. 1 spark plug wire

(front cylinder).

2. Start the engine and let it run at idle.

3. Check the timing on the crankshaft pulley, in relation to

the pointer on the timing cover.

4. Timing should be:

Past Production Units.......... 11° BTDC ± 1°

Current Production Units.......10° BTDC ± 1°

5. If timing needs to be adjusted. Loosen the distributor

hold down clamp screw and turn the distributor

clockwise or counterclockwise to adjust the timing.

6. After adjusting the timing, tighten the distributor clamp

screw, turn the engine off and remove the timing light.

Verify each item below: Remedy for each item:

Verify that there are no

leaks into the vacuum port

on the LPG mixer.

Replace or repair the hose.

Check for clogged air filter. Repair or replace.

Check for exhaust leaks

before the O2 sensor.

Repair air leaks in the

exhaust system.

Verify that the O2 sensor is

working properly.

See Error Code 13.

Verify idle air screw is

adjusted at idle. Fuel trim

valve will have a 50% duty

cycle.

Turn the adjustment screw

counterclockwise to lean

out the air/fuel mixture.

Check for faulty LPG

vaporizer.

Replace if LPG vapor

pressure is not greater that

Atmospheric pressure -

“W.C.

Verify each item below: Remedy for each item:

Check fuel shut-off valve.

Cycle ignition switch ON/

OFF, fuel shut-off valve

should click off after 2

seconds.

Check for obstructions in

fuel line.

Check wiring and fuse/

relay.

Clogged LPG filter.

Close liquid fuel tank valve.

Repair or replace LPG

filter. Open liquid fuel tank

valve and check for leaks.

Check for stuck open

vacuum valve.

Clean valve. Check wiring.

Check for clogged small air

filter on top of the

vaporizer.

Clean or replace air filter

and orifice jet.

Check for carburetor

malfunction.

Check diaphragm for hoe

and damage. Repair or

replace.

Past Production Units 0.035 in (0,90 mm)

Current Production Units 0.030 in (0,0762 mm)

Reference Only

Loading...

Loading...