STRUCTURALS 5540F/YB5515 SERVICE MANUAL

11-12

22. Install the pin and cotter pin securing the telescope

cylinder bracket to the rear of boom section 2. (Refer to

figure 9-11)

23. Raise up on the boom section 3 assembly and install the

front lower wear pads in the boom section 2.

24. Install the wear pad retainer plates to the front of boom

section 2 and secure with the bolts and lock washers.

25. Install the top rear wear pads on boom section 2.

26. Tighten the front top and bottom side wear pad set

screws on boom section 2 to center the assembly in

boom section 2.

NOTE: Refer to Figure 11-7 for steps 27 thru.

27. As necessary, install the following items on the boom

section 1:

a. Wire rope guide.

b. Boom angle indicator.

c. Anti-two block and LMI components.

d. Jib attachment brackets.

e. Upper rear cable wear pad.

f. Grease fittings and boom pivot pin bushings.

g. Install the front top and bottom side wear pads,

plugs and set screws. Do not tighten set screws at

this time

28. Slide the assembly into the boom section 1.

29. Install the nut, washer, and cotter pin securing the upper

telescope cylinder rod to the rear of boom section 1.

(Refer to figure 9-11)

30. Raise up on the boom section 2 assembly and install the

front lower wear pads in the boom section 1.

31. Install the wear pad retainer plates to the front of boom

section 1and secure with the bolts and lock washers.

32. At the rear of the assembly, install the hoses and fittings

to the telescope cylinder.

33. Tighten the front top and bottom side wear pad set

screws on boom section 1to center the assembly in the

boom section 1.

WIRE ROPE, SHEAVES AND HOIST

BLOCKS

Wire Rope Description

A wire rope is a machine, by definition: "An assemblage of

parts that transmit forces, motion and energy from one to

another in some predetermined manner and to some desired

end."

A typical wire rope may contain dozens, even hundreds, of

individual wires which are formed and fabricated to operate

at close bearing tolerances one to another. When a wire rope

bends, each of its many wires slide and adjust in the bend to

accommodate the differences in length between the inside

and the outside of the bend. The sharper the bend, the

greater the movement.

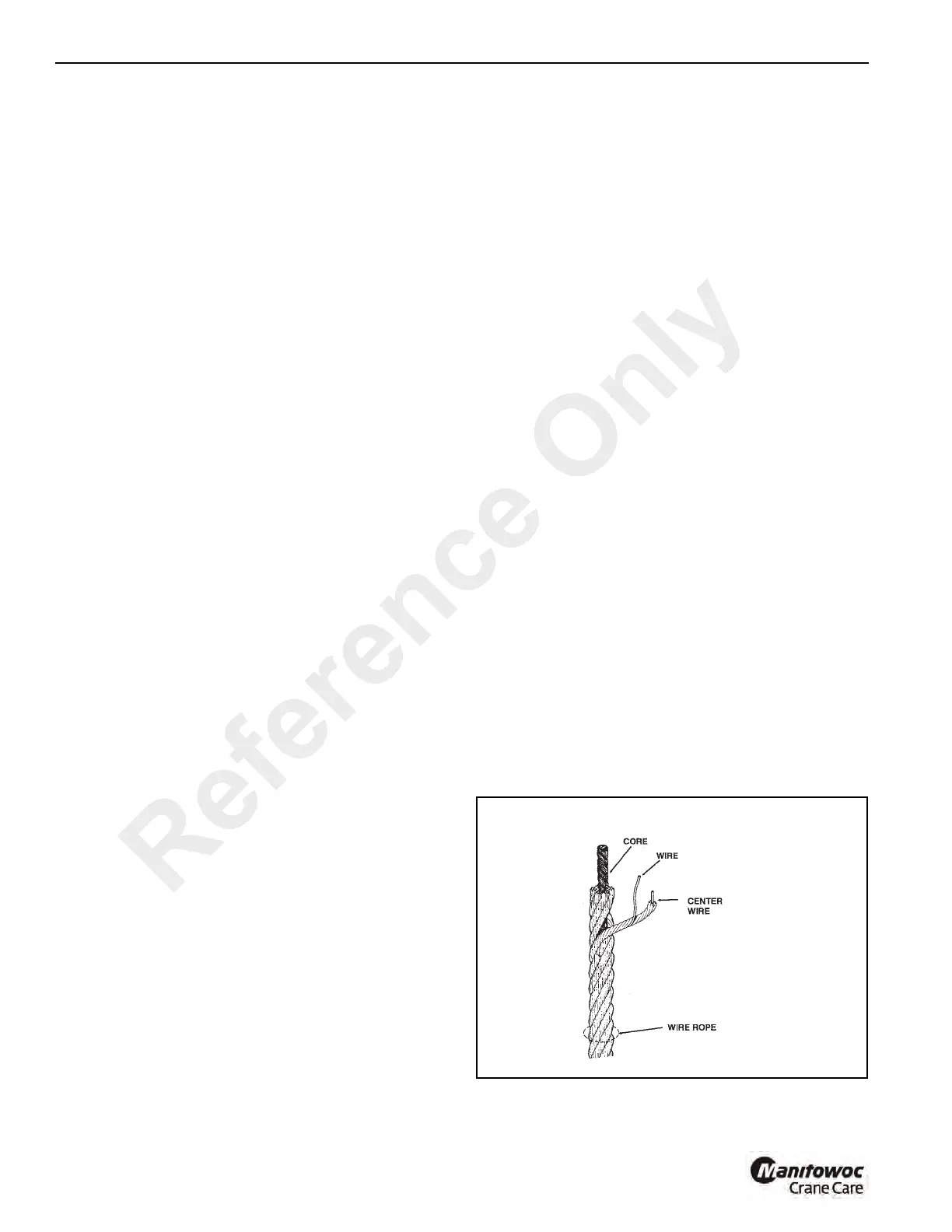

Every wire rope has three basic components (Figure 11-12):

(1) The wires which form the strands and collectively provide

rope strength; (2) the strands, which are laid helical around

the core, and (3) the core, which forms a foundation for the

strands. The core used in the crane wire rope is an

Independent Wire Rope Core (IWRC), which is actually a

smaller rope, or a strand similar to the outer strands of the

rope. The IWRC core adds about 7.5% to the nominal

strength of the wire rope.

The greatest differences in wire ropes are found in the

strands, which may vary widely in the pattern and number of

wires which are laid together.

The wires of the rope may be made of various metals,

including steel, iron, stainless steel, monel, and bronze. The

materials of which wires are made is the primary

determination of rope strength. High-carbon steel is used in

the crane wire rope.

Carbon steel wire ropes come in various grades. The term

“Grade” is used to designate the nominal strength of the wire

rope. The most common grades are Traction Steel (TS),

Plow Steel (PS), Improved Plow Steel (IPS), Extra Improved

Plow Steel (EIPS) and Extra Extra Improved Plow Steel

(EEIPS). The wire rope used on this crane is an EIPS Grade.

One cannot determine the grade of wire rope by its feel or

appearance. To be sure you are using the proper rope,

always obtain the wire rope from your dealer.

Reference Only

Loading...

Loading...