UNDERCARRIAGE RT530E-2 SERVICE MANUAL

8-28 Published 4-22-15, Control # 556-00

Outrigger Beam

Description

The outrigger beam assembly (Figure 8-20) consists of an

outrigger beam, a jack cylinder, an extension cylinder, an

Outrigger Monitoring System (OMS) (Optional—Standard in

North America), string potentiometer, and the required hoses

and mounting hardware.

Theory of Operation

When the outrigger extension is activated, it extends or

retracts the outrigger beam within the outrigger box. The

outrigger beam can be extended to the mid-extend position

by allowing the lock pin to ride on the top of the beam while

it’s extending. The lock pin will automatically drop into the

hole when the beam reaches the mid-extend position.

The stabilizer cylinder is mounted to the end of the beam and

applies force to the outrigger beam vertically. This sequence

of events provides for lifting and stabilizing the crane for

operation.

The jack cylinder is mounted to the end of the beam and

applies force to the outrigger beam vertically. This sequence

of events provides for lifting and stabilizing the crane for

operation.

Maintenance

Removal

1. On the jack cylinder end of the beam, remove the set

screw from the side adjustable wear pad and back off

the wear pad from the outrigger box.

2. Remove the cover from the opposite end of the outrigger

box. Remove the setscrew from the side adjustable wear

pad and back off the wear pad from the beam.

3. Remove the setscrews from the bottom adjustable wear

pads and back off the wear pads leaving approximately

6 mm (0.23 in) protruding

4. Extend the outrigger slightly to facilitate attaching a

lifting device to the outrigger beam.

5. Place blocking material under the outrigger beam.

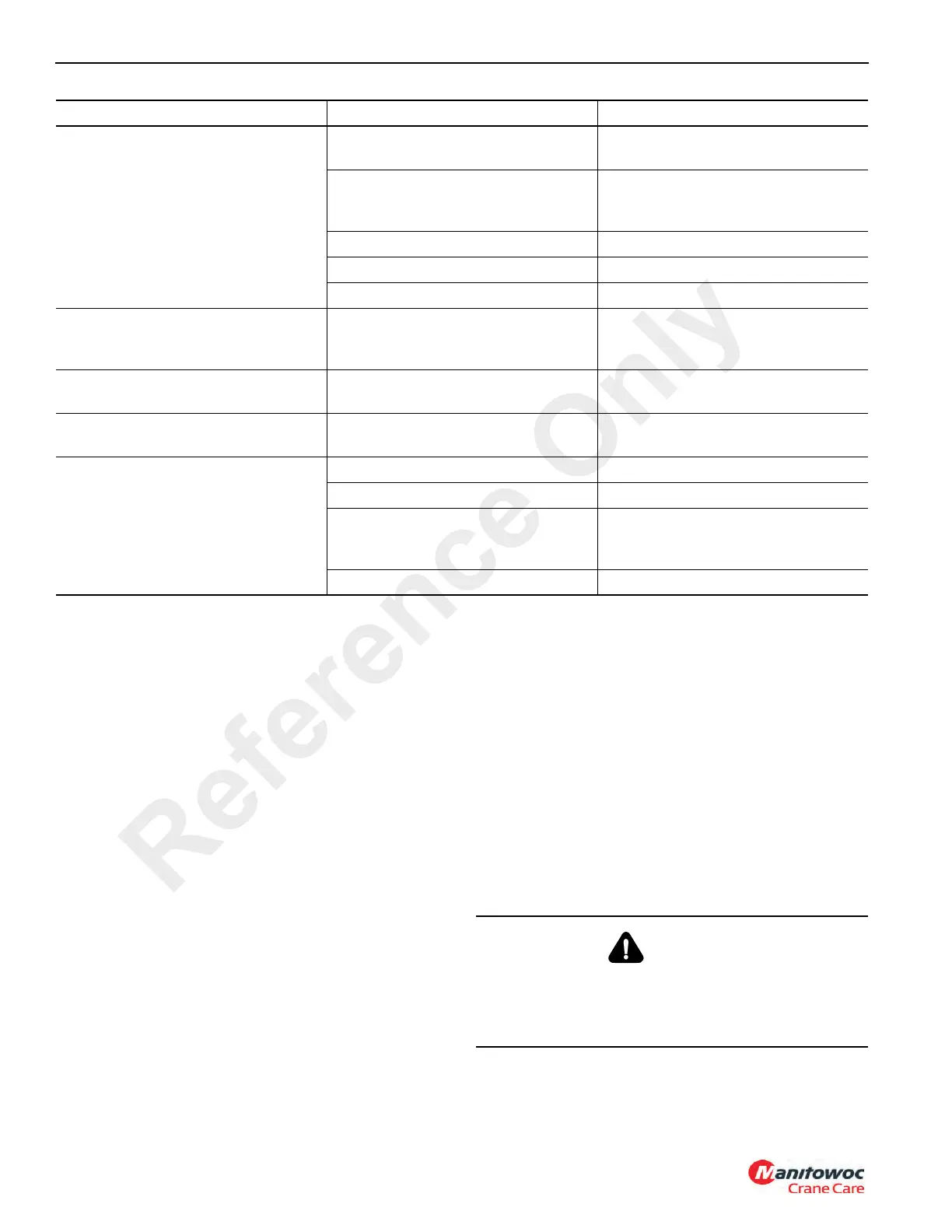

9. Outrigger system activates, but

selected outrigger will not stow or

extend and lower as desired.

a. Clogged, broken, or loose

hydraulic lines or fittings.

a. Clean, tighten, or replace

lines or fittings.

b. Loose or broken wire on

control switch or solenoid

valve.

b. Repair or replace wiring.

c. Damaged solenoid valve. c. Repair or replace valve.

d. Damaged control switch. d. Replace switch.

e. Damaged hydraulic cylinder. e. Repair or replace cylinder.

10. Outriggers will not set. a. Improper sequence of

activation.

a. Activate individual control

switch; then activate system

control switch.

11. Two outriggers activate from

single control switch.

a. Damaged solenoid valves. a. Repair or replace.

12. The two outriggers will not stow. a. Hydraulic lock. a. Recycle individual

outrigger(s).

13. Individual outrigger will not set or

stow.

a. Damaged piston seals. a. Replace seals.

b. Damaged check valve. b. Repair or replace valve.

c. Loosen or broken wire on

control switch or solenoid

valve.

c. Repair or replace wiring.

d. Damaged solenoid valve. d. Repair or replace valve.

Symptom Probable Cause Solution

DANGER

Be sure any blocking material used is capable of

supporting the weight of the outrigger beam. Do not allow

it to tilt or slide. Failure to do so could result in death or

injury to personnel.

Reference Only

Loading...

Loading...