6-21

Published 11/26/2014, Control # 447-05

RT770E SWING SYSTEM

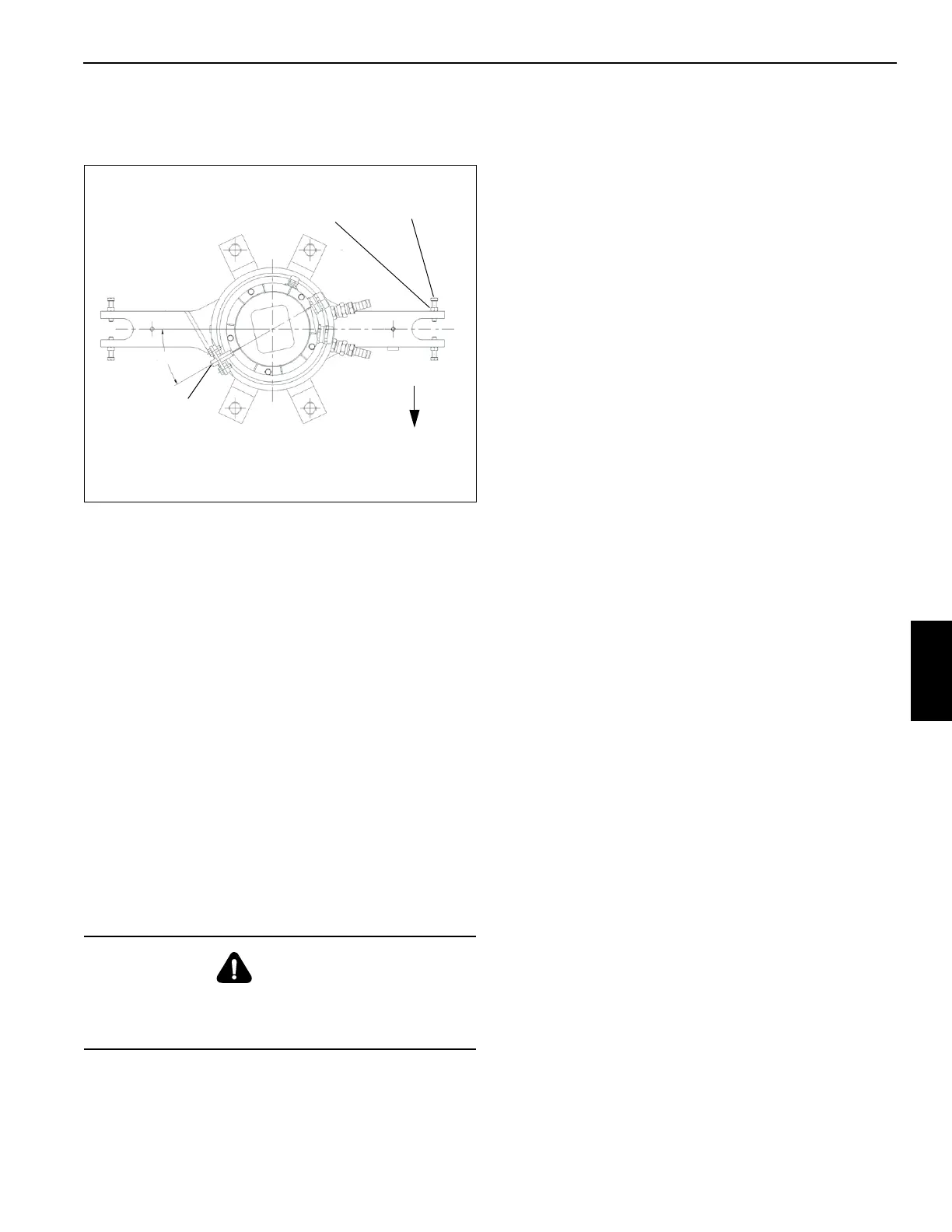

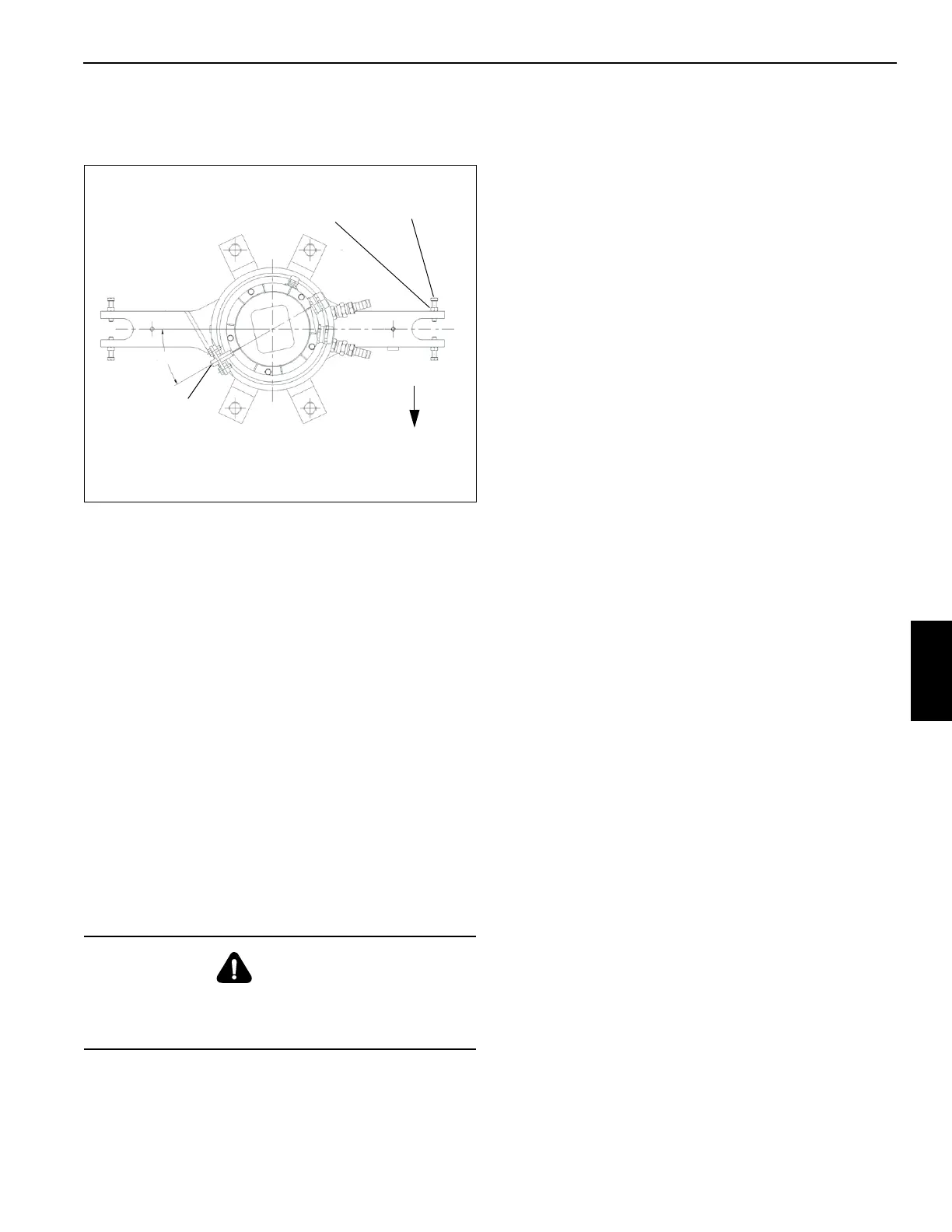

3. Ensure the anti-rotation pin in the bottom of the electrical

swivel base is aligned with the mounting hole in the

bracket on the water swivel case (Figure 6-6).

4. Apply medium strength Loc-tite to the set screws

securing the electrical swivel to the center post and

tighten them 45 to 55 lb-in (5 to 6 Nm). Tighten the jam

nuts.

5. Connect the wiring harness connectors to the

receptacles on the cab bulkhead mounting plate as

tagged during removal.

6. Unbundle the wires of the collector core wiring harness.

Install the pins, with wire attached, to the connector as

tagged during removal.

7. Plug the connector into the carrier wiring receptacle,

connect the wires as tag during removal. Install the

yellow ground wire to the connector mounting bracket on

the carrier frame using the bolt and star washers taken

of at removal and refer to Grove Engineering

Specification 6829100386 for proper electrical

termination of grounds.

8. Install the clamp securing the harness to the retainer

plate on the bottom of the hydraulic swivel assembly.

9. Connect the batteries.

10. Activate all systems, cycle all functions, and observe for

proper operation. Adjust the slew angle in accordance

with Slew Angle Verification, page 6-21.

Preventive Maintenance

It is recommended that a normal inspection of the electrical

swivel collector ring and brush assembly be established. An

example of this could be at approximately 100 to 150 engine

operating hours. When this time limit is reached, perform the

following.

1. Check the collector ring and brush assembly for any

corrosion, pitting, arcing, and wear.

2. Check the collector ring setscrews and ensure they are

tight.

3. Check the brush and arm assembly springs. Ensure

they are holding the brushes firmly against the collector

rings.

Slew Angle Zero Adjustment Procedure

1. Rotate the superstructure over the front and engage the

lock pin.

NOTE: Refer to the Hirschmann Rated Capacity Limiter

Operator’s Handbook for detailed instructions.

Complete the RCL console setup according to the

crane’s current operating configuration.

2. Select the Info icon.

3. Select the Info icon.

4. Enter authorization code 64356, then select return.

5. Select return until the slew adjustment screen is

displayed.

6. Select the Auto 0 (zero) icon. Note the indicator line

moves to zero on the bar graph on the slew adjustment

screen.

7. Press the ESC keypad button on the RCL console.

Slew Angle Verification

1. Rotate the superstructure over the front and engage the

house lock pin.

2. Set the RCL console to read slewing angle as follows:

NOTE: Refer to the Hirschmann Rated Capacity Limiter

Operator’s Handbook for detailed instructions.

• Complete the RCL console setup according to the

crane’s current operating configuration.

• Select the Info icon.

• Select the Info icon.

3. Verify the angle indicated on the console does not

exceed ± 1.0 degree.

CAUTION

It is most important that the slew potentiometer be

adjusted anytime work is done to the electrical swivel.

Personnel injury or damage to the machine may result.

FIGURE 6-6

Anti- Rotation

Pin

30°

Forward

Hex Nut

Capscrew

Loading...

Loading...