GROVE Published 1-20-2017, Control# 483-02 6-3

CD5515-2/YB5515-2 SERVICE MANUAL ENGINE AND ENGINE SYSTEMS

protection will never be required, use a non-chromate

corrosion inhibitor and clean soft water. Change the

water/corrosion inhibitor every 12 months, or 500 hours,

or to manufacturer’s recommendation.

Do not use hard water in the cooling system. Hard

water, or water with high levels of calcium and

magnesium ions, encourages silica gel formations,

especially after a number of heating and cooling cycles.

These gel formations can result in loss of cooling or

heating in radiators and cab heater cores by coating and

plugging the tubes. The formations usually deposit in the

cooler sections of the cooling system, such as the

radiator bottom tank.

Use soft water, distilled water or deionized water to

reduce the potential and severity of silicate dropouts.

NOTE: If you use water without a corrosion inhibitor, rust

will form and plug the small holes in the head

gasket. These holes are orifices and their size is

critical. Do not enlarge the size of the orifices. To do

so will disturb the coolant flow and will not solve

any overheating problem. If you use water without

a corrosion inhibitor for even a short period, the cup

plugs will rust through, allowing coolant leakage.

An incorrect or malfunctioning radiator cap can

result in the loss of coolant and engine running hot.

Any sudden loss of coolant from a heavily loaded

engine can result in severe damage to the pistons

and cylinder bore.

NOTE: Some corrosion inhibitor mixtures contain soluble

oil which can have an adverse effect on some

types of water hoses.

Radiator Cap and Overflow Bottle

The cooling system is designed to use a radiator cap to

prevent the boiling of coolant. The radiator cap is set to open

at 0.97 bar (14 psi). When it does open it allows coolant to be

expelled into the overflow bottle and as soon as the engine

cools the overflow fluid is sucked back into the radiator. An

incorrect radiator cap can result in a great loss of coolant and

the engine running hot.

Keep the overflow bottle at least half full of coolant at all

times.

Thermostat

A malfunctioning thermostat can result in the engine running

hot or cold. If it becomes necessary to replace the thermostat

see the engine manual furnished with the crane.

ENGINE ELECTRICAL SYSTEM

The engine electrical system, the charging and starting

circuits, as well as the sending units, are described in this

section.

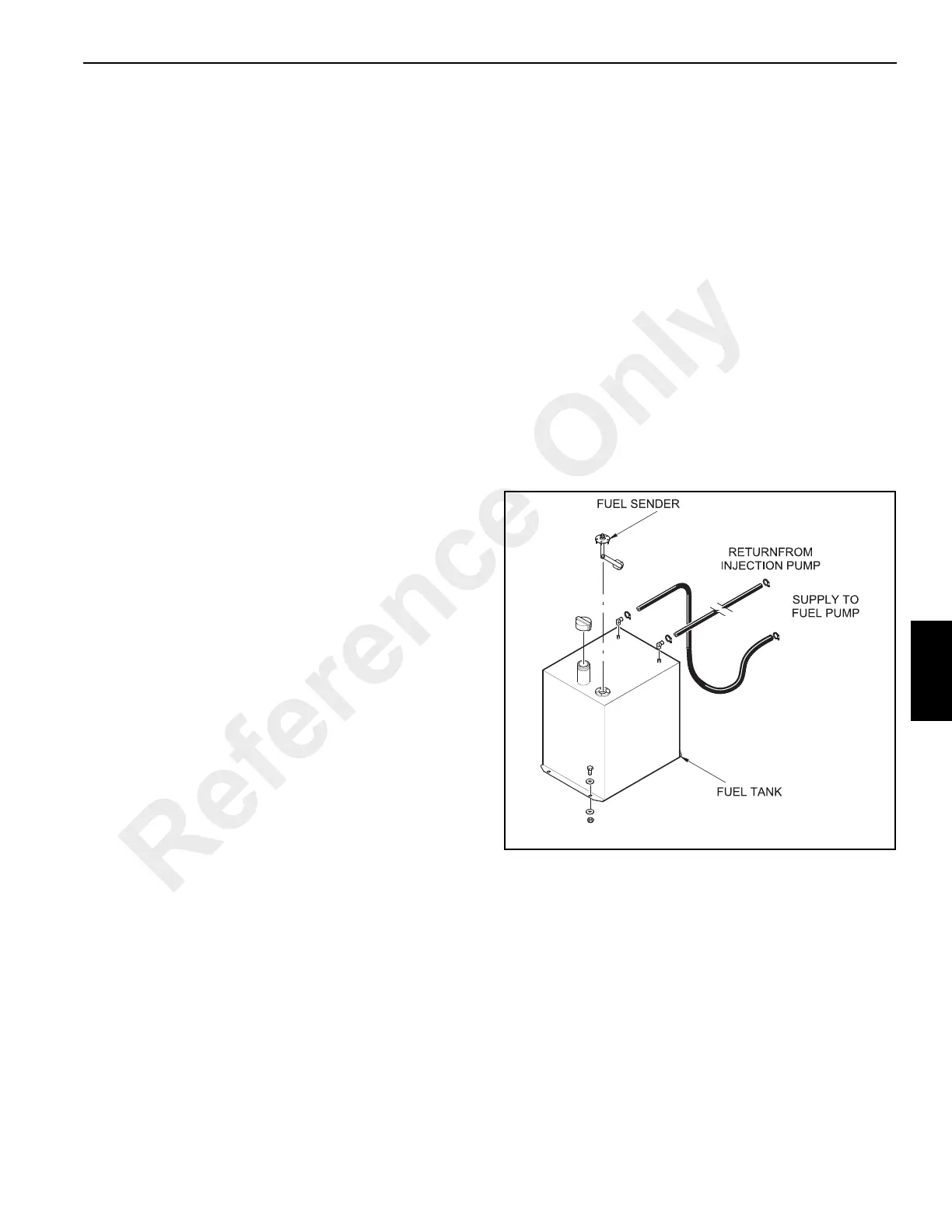

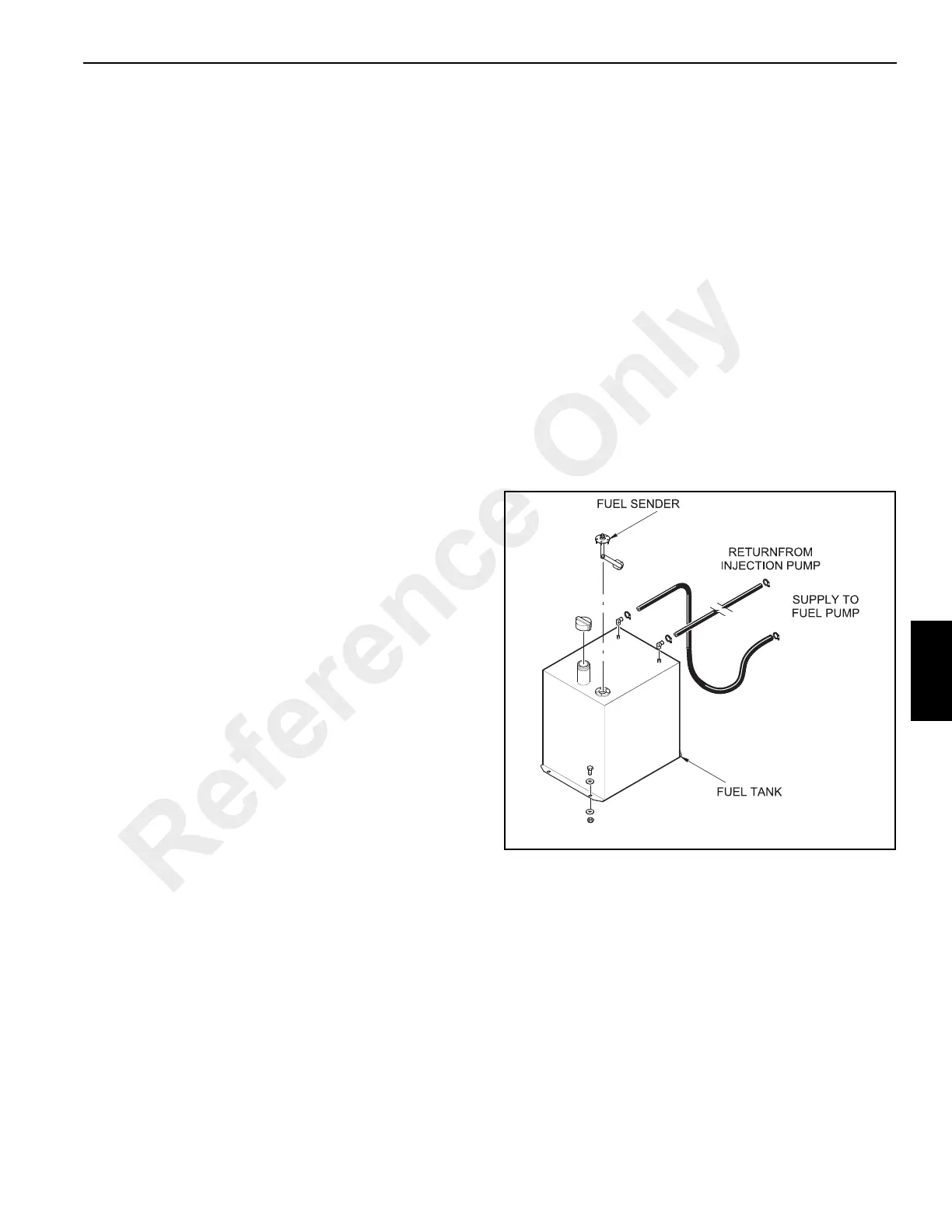

ENGINE FUEL SYSTEM

Diesel Engine Fuel System Description

The diesel engine fuel system is a closed-loop fuel system

which includes a fuel tank, an engine fuel filter, an engine

fuel pump and the fuel lines.

A fuel supply line carries fuel from the bottom of the fuel tank

to the engine fuel pump Figure 6-2. A line carries the fuel

from the engine fuel pump to the engine fuel filter. Fuel that

has been filtered flows to the fuel injector pump.

Fuel is distributed to the fuel injectors from the fuel injector

pump. Excess fuel from the fuel injector pump is returned to

tank.

Fuel Tank

The fuel tank is located on the right side of the crane. It is a

welded box construction with a suction tube installed in the

fuel support port. The tube inhibits sediment and water from

being picked up off the bottom and sent to the engine.

Fuel Level Sender and Gauge

The fuel level sender and gauge are described in the Section

11, Electrical System.

Fuel Pump

The fuel pump is installed internally in the engine and is used

to pump fuel from the fuel tank and send it under pressure to

the fuel filters and injection pump.

The fuel pump includes a priming button. This button is used

to bleed the fuel system if one of the following should occur:

• The fuel filter is not filled prior to installation.

• The injection pump is replaced.

A1768

FIGURE 6-2

Diesel Fuel System

Reference Only

Loading...

Loading...