HYDRAULIC SYSTEM CD5515-2/YB5515-2 SERVICE MANUAL

4-8 Published 1-20-2017, Control# 483-02

HYDRAULIC SYSTEM

System Description

The hydraulic system is a closed-center hydraulic system

with pressure compensated load sensing characteristics

driven by a variable displacement axial piston pump.

Hydraulic Pump

Description

The hydraulic pump is a variable displacement axial piston

pressure compensated pump. The pump generates a fluid

flow and imparts to that fluid the necessary pressure forces

to obtain the hydraulic system pressure.

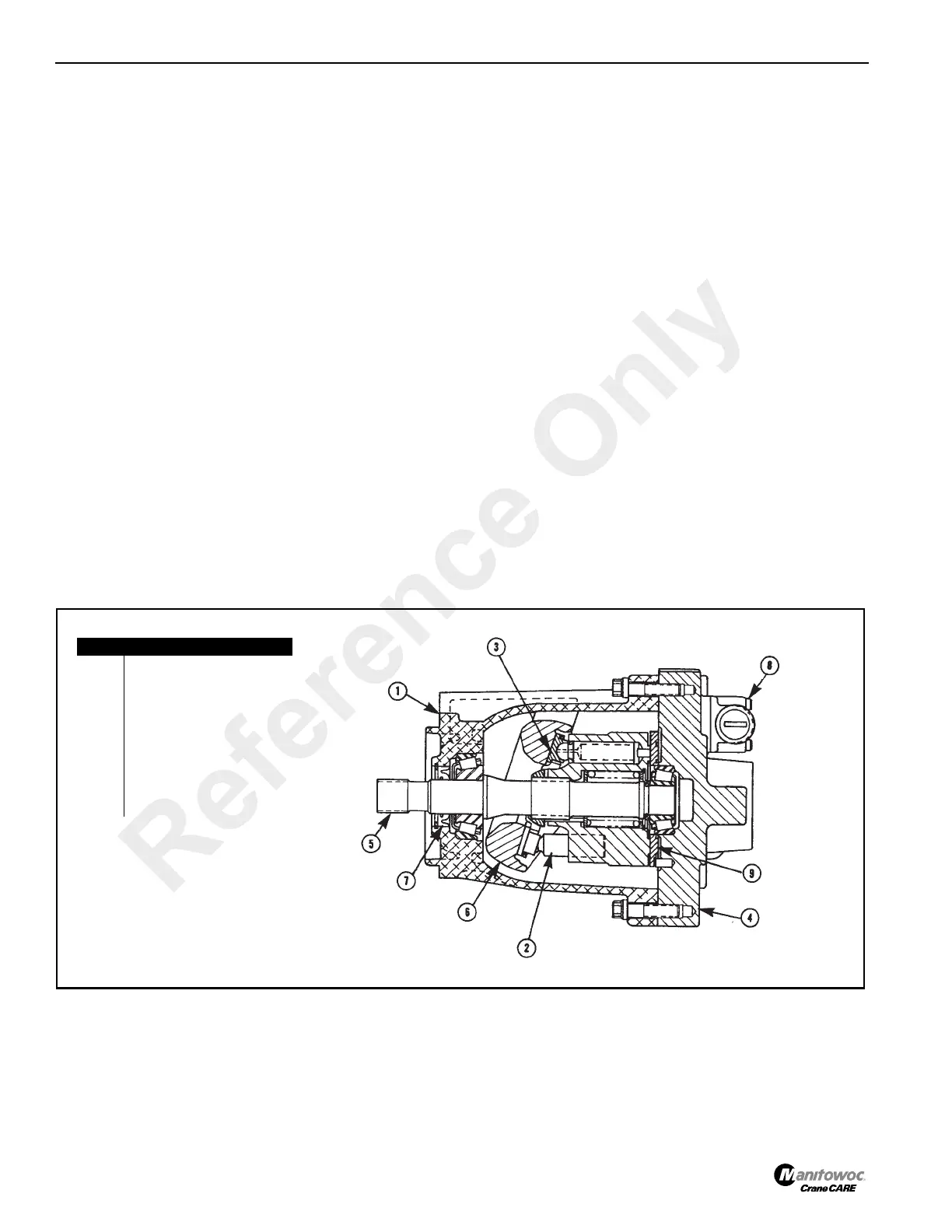

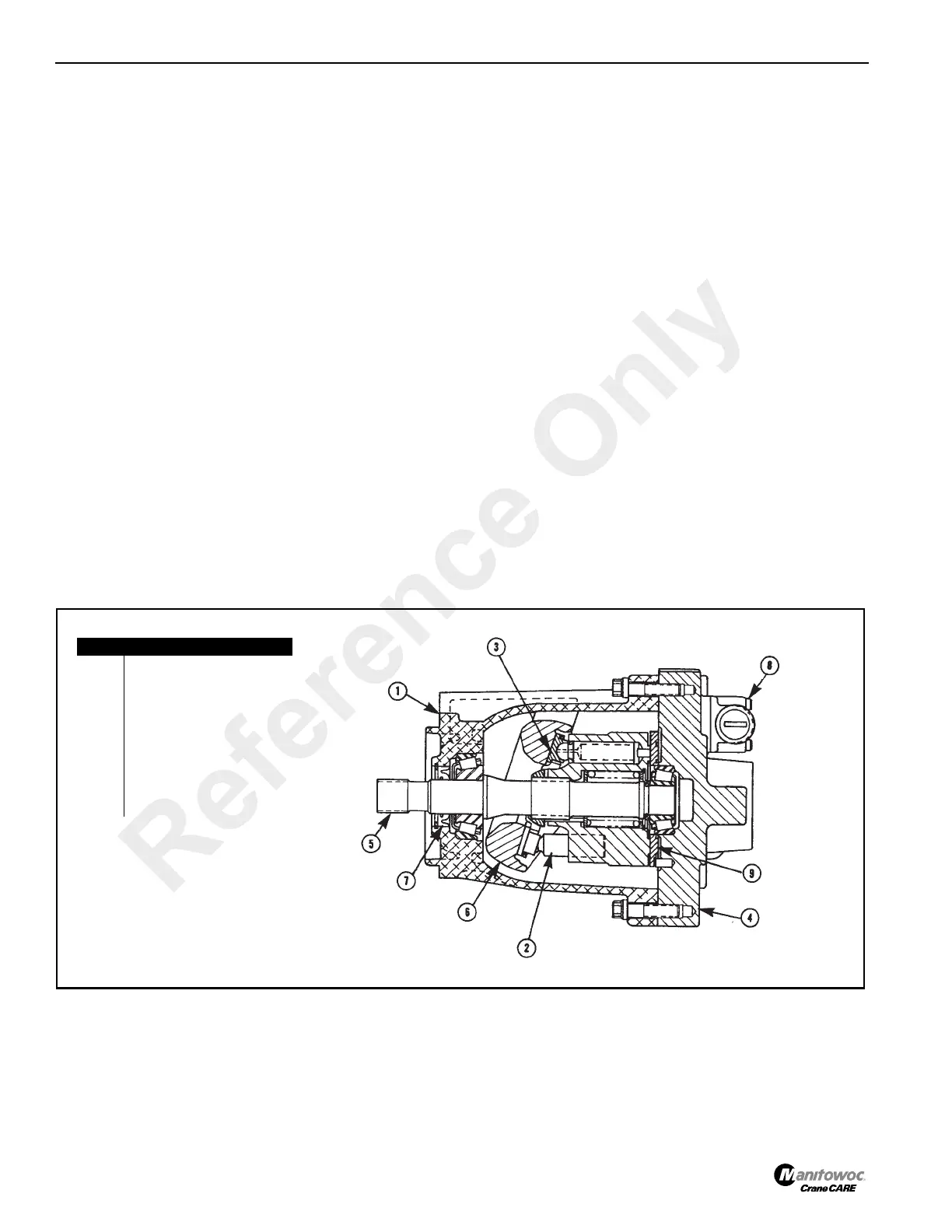

The pump basically consists of the housing (1, Figure 4-1),

piston (2), shoes (3), port plate (4), drive shaft (5), swash

plate (6), shaft seal (7), compensator (8) and valve plate (9).

Rotation of the drive shaft (5) and control piston (not shown)

causes a linear piston movement as the piston shoe (3)

slides along the tilted swash plate (6). As the piston retracts

in the cylinder bore, hydraulic oil from the hydraulic oil tank

fills the developing vacuum cavity by way of the suction

kidney in the valve plate (9). At maximum retraction of the

piston, shaft rotation causes the piston to go beyond the

suction kidney and begin communication with the pressure

kidney. Continuing rotation then extends the piston into the

cylinder bore, forcing oil into the pressure port and out to the

hydraulic system.

Test - Pump Output

The hydraulic pump output can not be checked using a

flowmeter. The efficiency of the pump must be checked by

using function cycling speeds.

Pressure Regulation

System pressure is working on the pressure compensator

against a setting spring. When system pressure overcomes

the spring force, the spool shifts allowing system pressure

into the control piston. This causes the pump to stroke to a

regulating point sufficient to maintain the increased

compensator setting (system pressure) and the lubrication

fluid flow required.

When the system pressure setting is reached, only the

amount of fluid necessary to satisfy the load conditions is

delivered. If the load condition is such that no flow is

required, only cooling and lubricating fluid is delivered.

Power usage and heating of the fluid are kept to a minimum.

When the system pressure falls below the compensator

spring setting, spring force returns the spool back to the

normal position, which drains the control piston (2,

Figure 4-1) to the pump case drain. This causes the pump to

de-stroke, reducing the fluid flow to the level required.

Description of Operation

Hydraulic System

The hydraulic system is a closed-center hydraulic system.

Which means that hydraulic oil is blocked from returning to

tank when the valves spools are in the neutral position. The

control valve sections used in the hydraulic system of the

main control valve are pressure compensated valve sections

incorporating a flow divider principle in their operation. This

provides the ability to control multifunction operation when

flow demand exceeds pump capacity though slowed down

proportionally. This means that all circuits will continue to

FIGURE 4-1

Item Description

1 Housing

2Piston

3 Shoe

4 Port Plate

5 Drive Shaft

6Swash Plate

7 Shaft Seal

8 Compensator Control

9Valve Plate

a0727

Reference Only

Loading...

Loading...