GROVE Published 1-20-2017, Control# 483-02 10-25

CD5515-2/YB5515-2 SERVICE MANUAL STEERING SYSTEM

4. Fasten the bushing end of the cylinder rod in a vice. Do

not clamp a vise on the cylinder rod.

5. Remove and discard piston seal 9 and wear rings 10

from piston 7.

6. Remove dowel 8 from piston head 7 using a metric

screw threaded into the extraction hole in the dowel.

7. Using a special spanner wrench (See Special Tools on

page 10-24) remove the piston 7 from rod 16.

8. Remove and discard O-ring 11.

9. Remove cap end 13 from cylinder rod 16.

10. Remove and discard O-ring 12, seal gland 14 and wiper

seal 15 from cap end 13.

11. Remove and discard the oil seals 5 from both the rod

end and base ends of the cylinder.

Inspection

1. Clean all parts in a suitable solvent. Dry with

compressed air. Make sure threads of piston rod, piston,

end cap and cylinder are thoroughly cleaned using a

wire brush to remove grease, hydraulic oil and Loctite.

2. Inspect cylinder rod for rust, distortion, pitting or damage

to the chrome. If there is damage to the cylinder rod,

replace it. Do not try to straighten a bent cylinder rod.

3. Inspect inside of the cylinder barrel for grooves,

distortion or other damage. Use a light to illuminate the

cylinder bore for careful inspection. Replace any

cylinder barrel if there is distortion or damage.

4. Inspect the piston for damage to the lands.

5. Inspect rod and barrel bushings for wear or damage.

6. Replace all seals and rings.

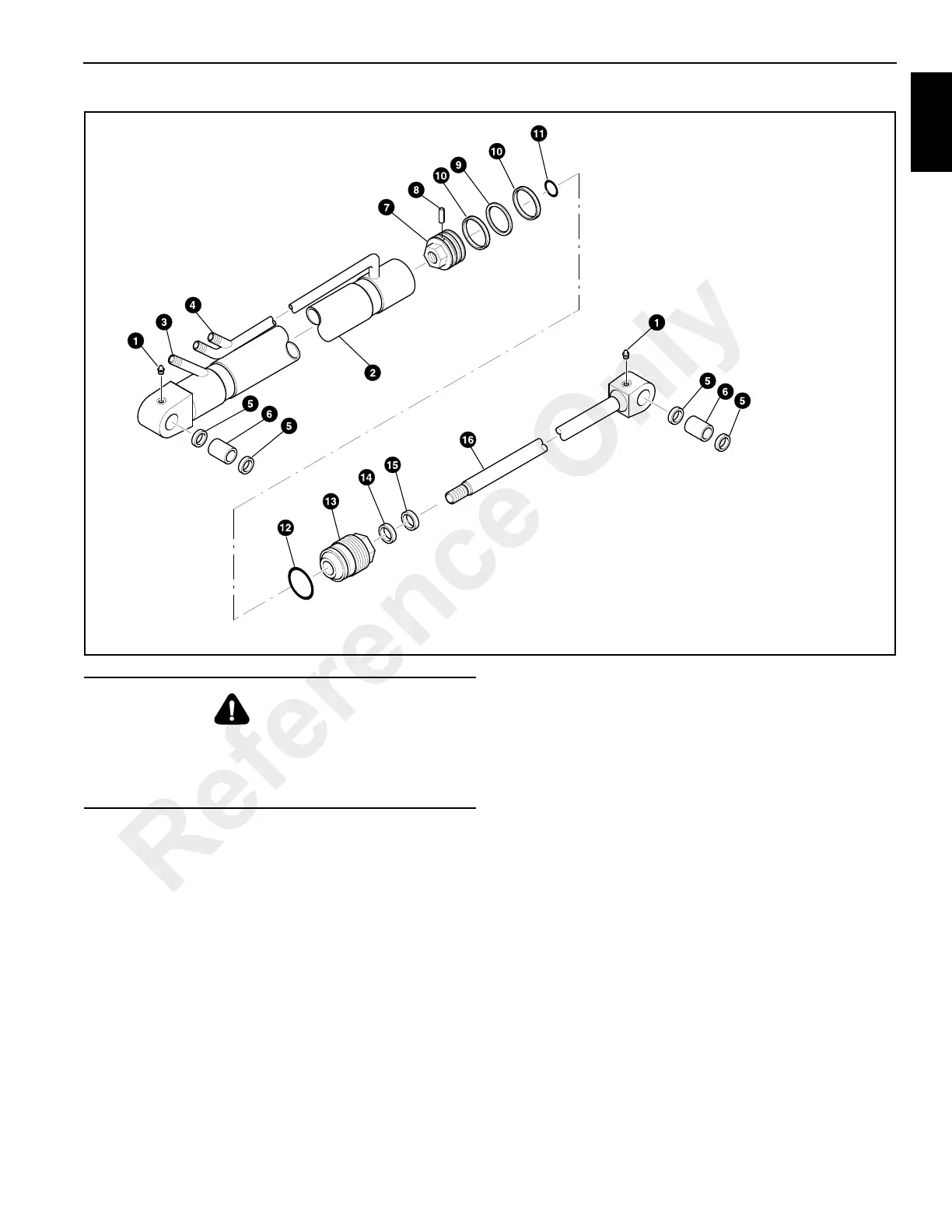

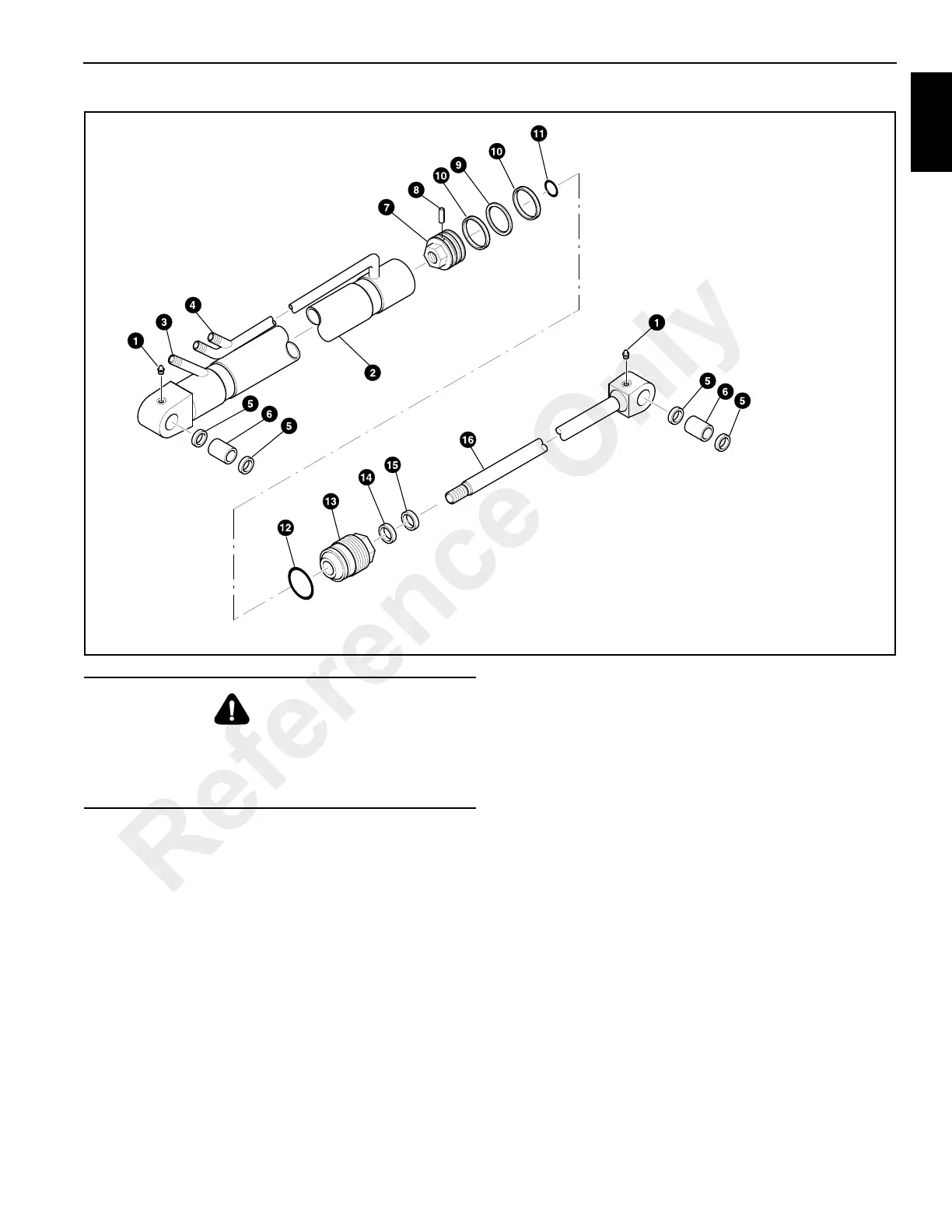

FIGURE 10-65

a0342

1. Grease Fitting (2)

2. Cylinder Barrel

3. Left Side Pipe

4. Right Side Pipe

5. Oil Seal (4)

6. Bushing (2)

8. Dowel

8. Piston

9. Piston Seal

10. Wear Ring

11. O-Ring

12. O-Ring

13. End Cap

14. Gland Seal

15. Wiper Seal

16. Cylinder Rod

CAUTION

If air or hydraulic pressure is used to force out the piston

assembly, ensure that the end cap is securely installed.

Severe injury can be caused by a sudden release of the

piston rod.

Reference Only

Loading...

Loading...