NomoLine ISA Service Manual Chapter 2: Maintenance Procedures

www.masimo.com 20 Masimo

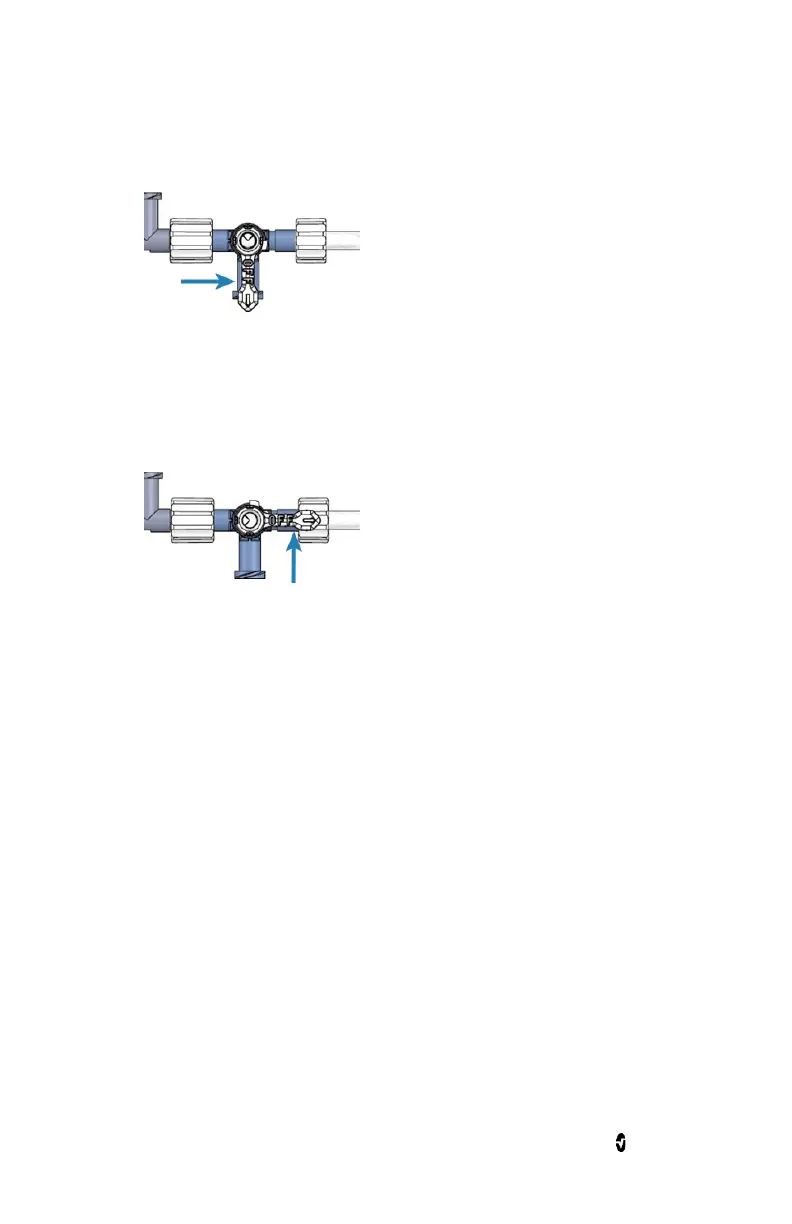

Figure 1-6

4. Check that the Input Connector is lit with a steady green light.

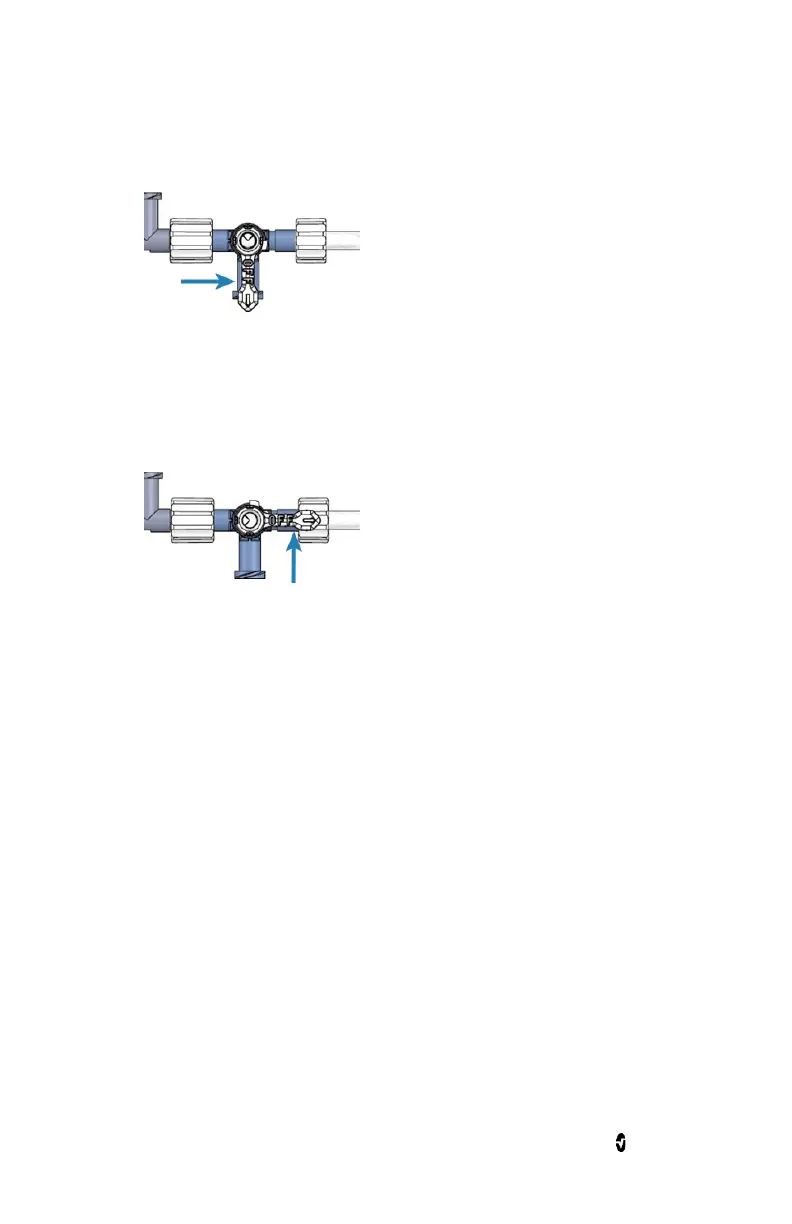

5. Occlude the sampling line by rotating the 4-way stopcock lever in the position

shown in figure 1-7 and wait for 10 seconds.

Figure 1-7

6. Verify that the host device shows an occlusion alarm and the Input Connector

shows flashing red light.

Test Result

The test is successful if an occlusion alarm is displayed on the host device and the Input

Connector shows a flashing red light. If the Input Connector is still lit with green light with

the 4-way stopcock blocked, the test needs to be repeated. Before performing the test again,

check that all connections on the NomoLine ISA Maintenance Kit are firmly tightened and

verify that the profiled sealing on the Nomo connector is undamaged. Do not operate the

NomoLine ISA system if the test fails repeatedly as this indicates a leakage in the NomoLine

ISA system.

Leakage Check

Setup

• Assemble the following components from the NomoLine ISA Maintenance Kit as

shown in figure 1-8. Refer to Maintenance Kit Components on page 14 for

component identification.

• Nomo connector with tubing (connects to the NomoLine ISA system Input

Connector)

• Flow-check device with silicone tubing (connects to NomoLine ISA system

Exhaust Port)

• Syringe

Loading...

Loading...