25

Installation

Receiving

All units leaving the McQuay plant have been inspected to ensure the shipment of quality products. All

reasonable means are utilized to properly package the air handing units. Carefully inspect all shipments

immediately upon delivery. When damage is visible, note this fact on the carrier’s freight bill and request that

the carrier sends a representative to inspect the damage. This may be done by telephone or in person, but

should always be confirmed in writing. The shipment should be unpacked in the presence of the agent so

that the extent of the damage or loss can be determined. The carrier’s agent will make an inspection report

and a copy will be given to the consignee for forwarding to the carrier with a formal claim.

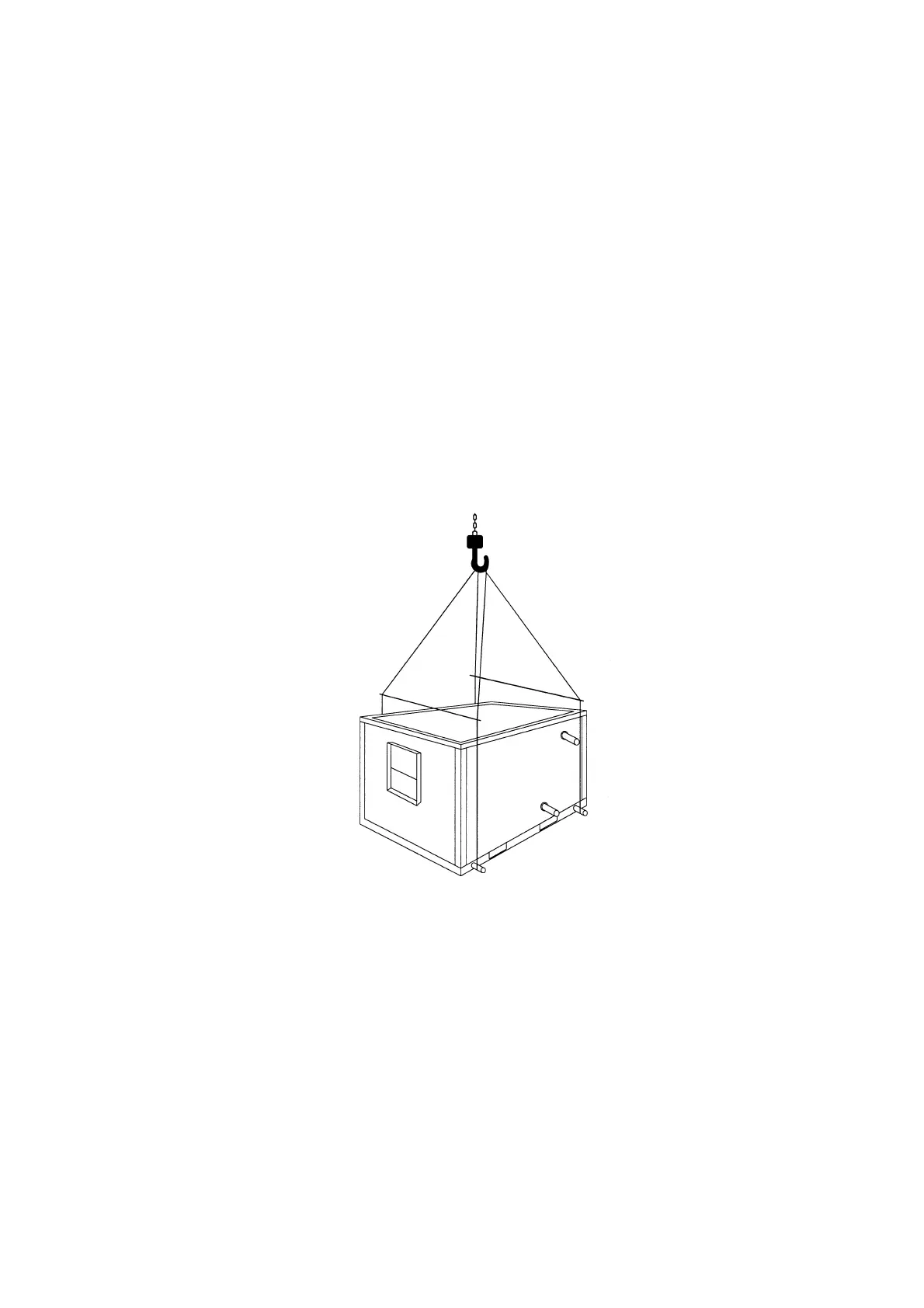

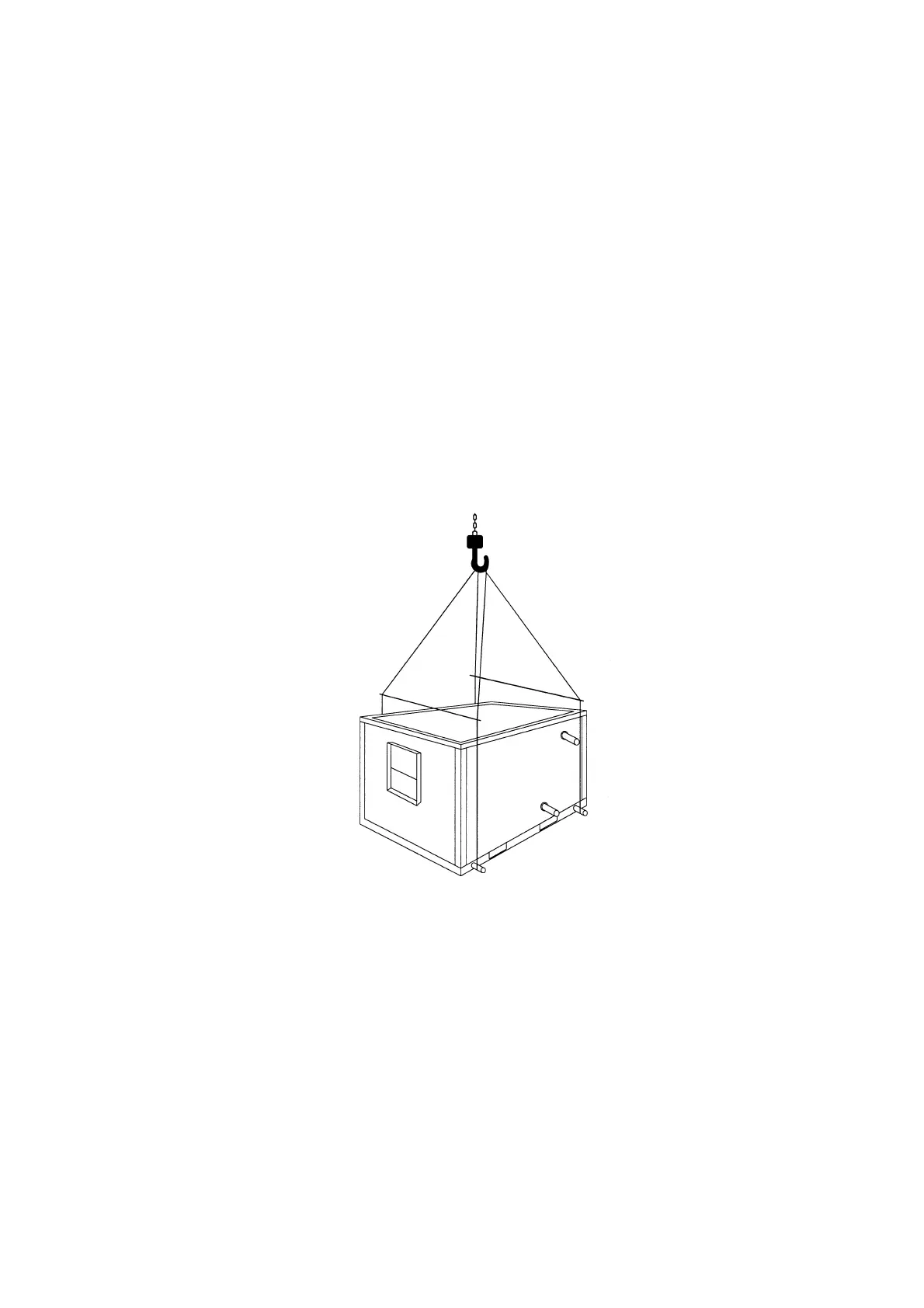

Rigging

Air handling units are shipped on skids with sections bolted together as determined by truck or rail size

limitations. Figure 1 illustrates the proper rigging to be used in moving the Air handling units. Ropes or

cables are to be placed around the unit across the bottom channels. Spreader bars must be used to avoid

damage to the top of the unit. Caution must be exercised to the coil connections, operator arm for units with

variable inlet vanes, and damper operators are not damaged.

Figure 1

Storage

If the units are to be stored out of doors, prior to installation within the building, special care should be taken

to protect the units from dust, rain, snow, and rodents. The units should be protected from constant

exposure to rain and snow.

Loading...

Loading...