35

Magnets

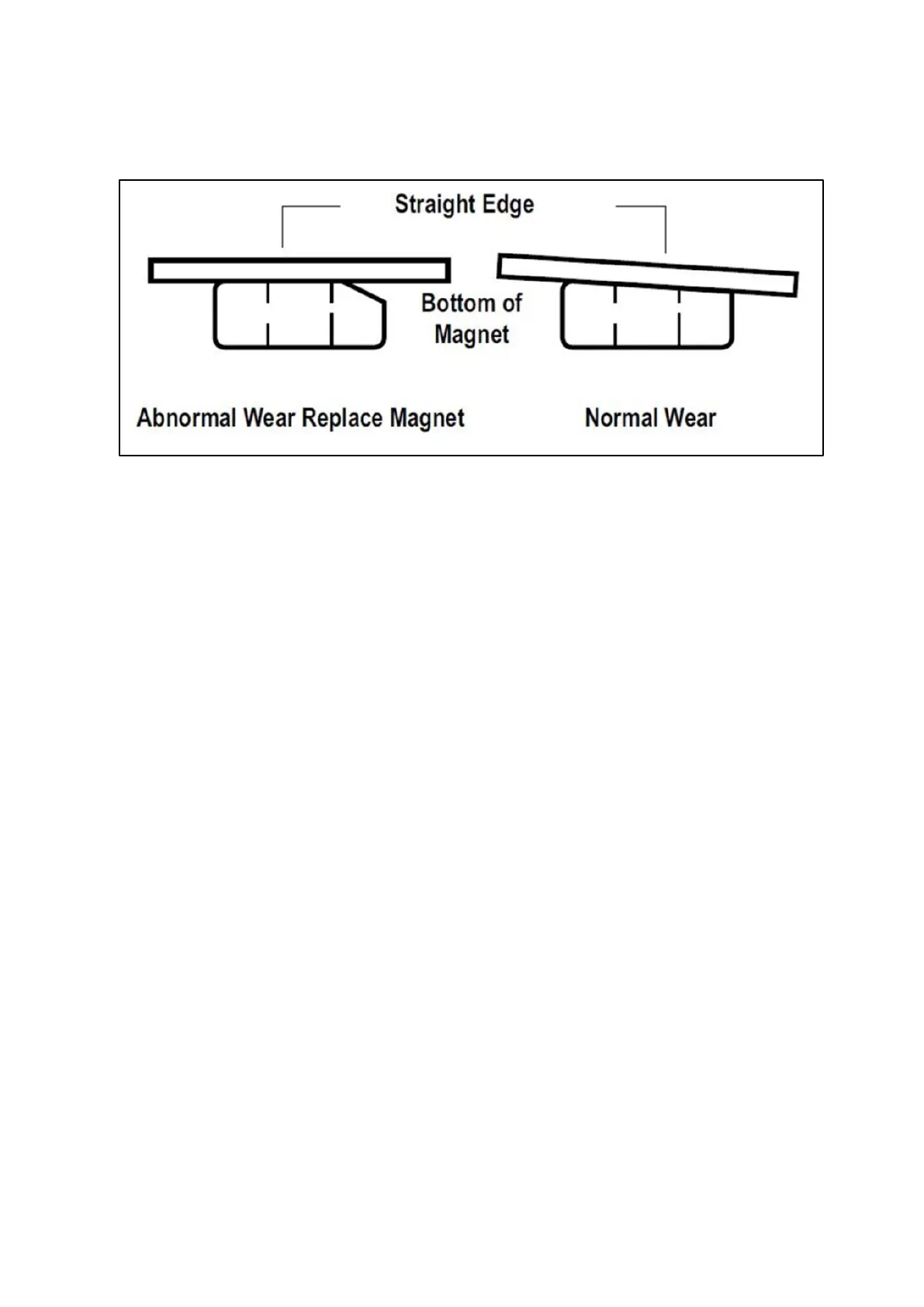

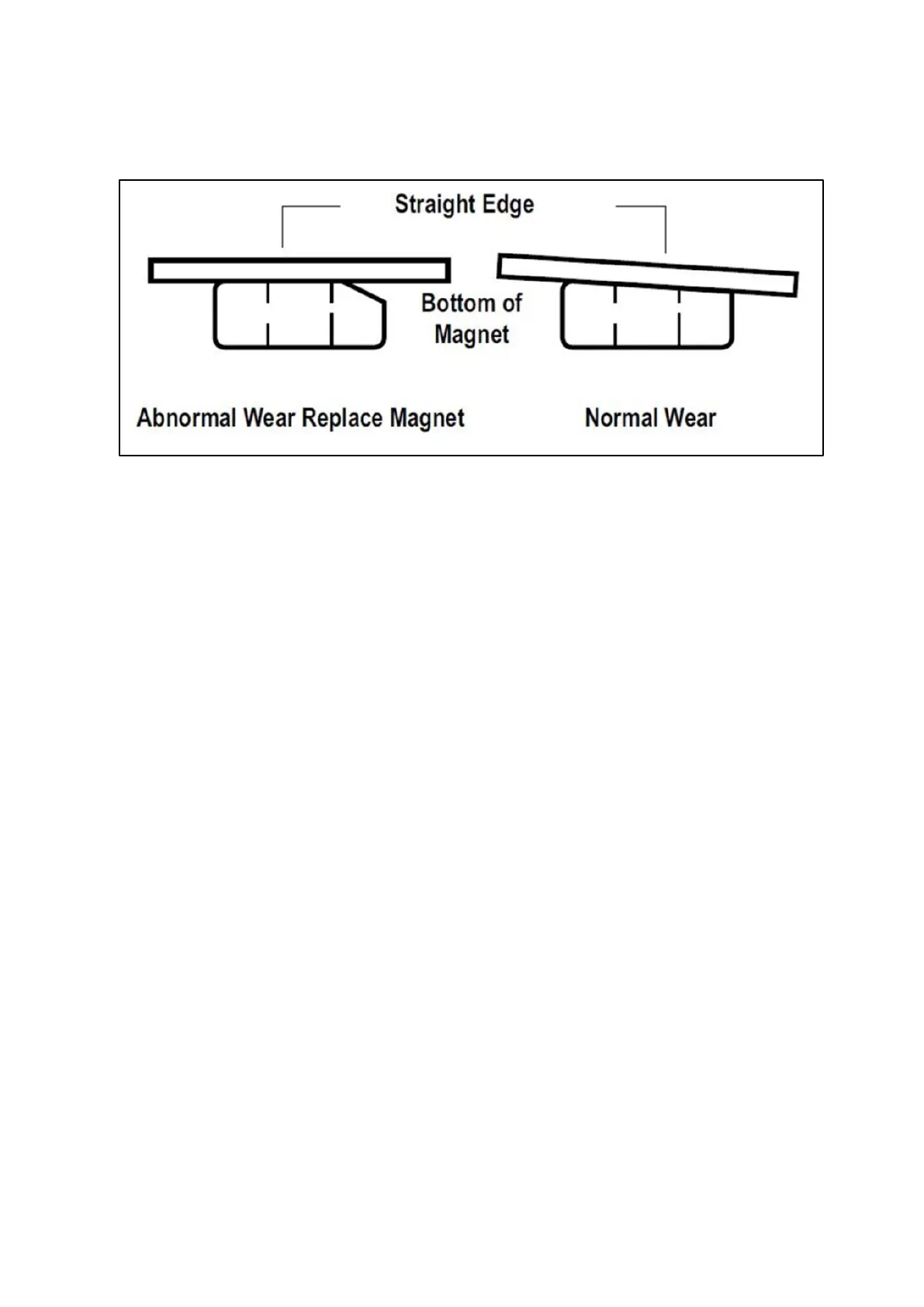

Your electric brakes are equipped with high quality electromagnets that are designed to provide the proper input force

and fricon characteriscs. Your magnets should be inspected and replaced if worn unevenly or abnormally.

Even if wear is normal as indicated by your straightedge, the magnets should be replaced if any part of the magnet coil

has become visible through the fricon material facing of the magnet. It is also recommended that the drum armature

surface be refaced when replacing magnets.

Magnets should also be replaced in pairs - both sides of the axle. Always use genuine MDC OEM parts.

Shoes and Linings

A simple visual inspecon of your brake linings will tell if they are useable.

Replacement is necessary if the lining is worn (to within 1.5mm or less), contaminated with grease or oil or abnormally

scored or gouged. It is important to replace both shoes on each brake and both brakes of the same axle. This is necessary

to retain the “balance” of your brakes. Be sure to replace your shoes only with genuine MDC parts available from our

outlets.

Corrosion Prevenon

It’s important to take steps to prevent corrosion of parts on your trailer to extend the service life. Many fings are high

tensile and therefor zinc plated. Fings such as this can benefit from addional protecon. Some helpful products to

prevent corrosion are “Lanotec”, “WD40”, “Inox” and similar products. These can be spray applied and do a very good job

of protecng metal surfaces, parcularly in corrosive and aggressive environments near the ocean and inland waterways.

Oen, we take our campers and caravans to saltwater environments. Driving through saltwater is never recommended as

the residual chloride ions accelerate corrosion greatly. If you are camping near or driving through these kinds of

environments, we highly recommend that your trailer be thoroughly cleaned aer use. Flushing the chassis and washing

and rinsing your trailer is important.

Loading...

Loading...