Page 40 85

-

J - Operator’s Manual - 95803

January 2024Section 8 - Maintenance

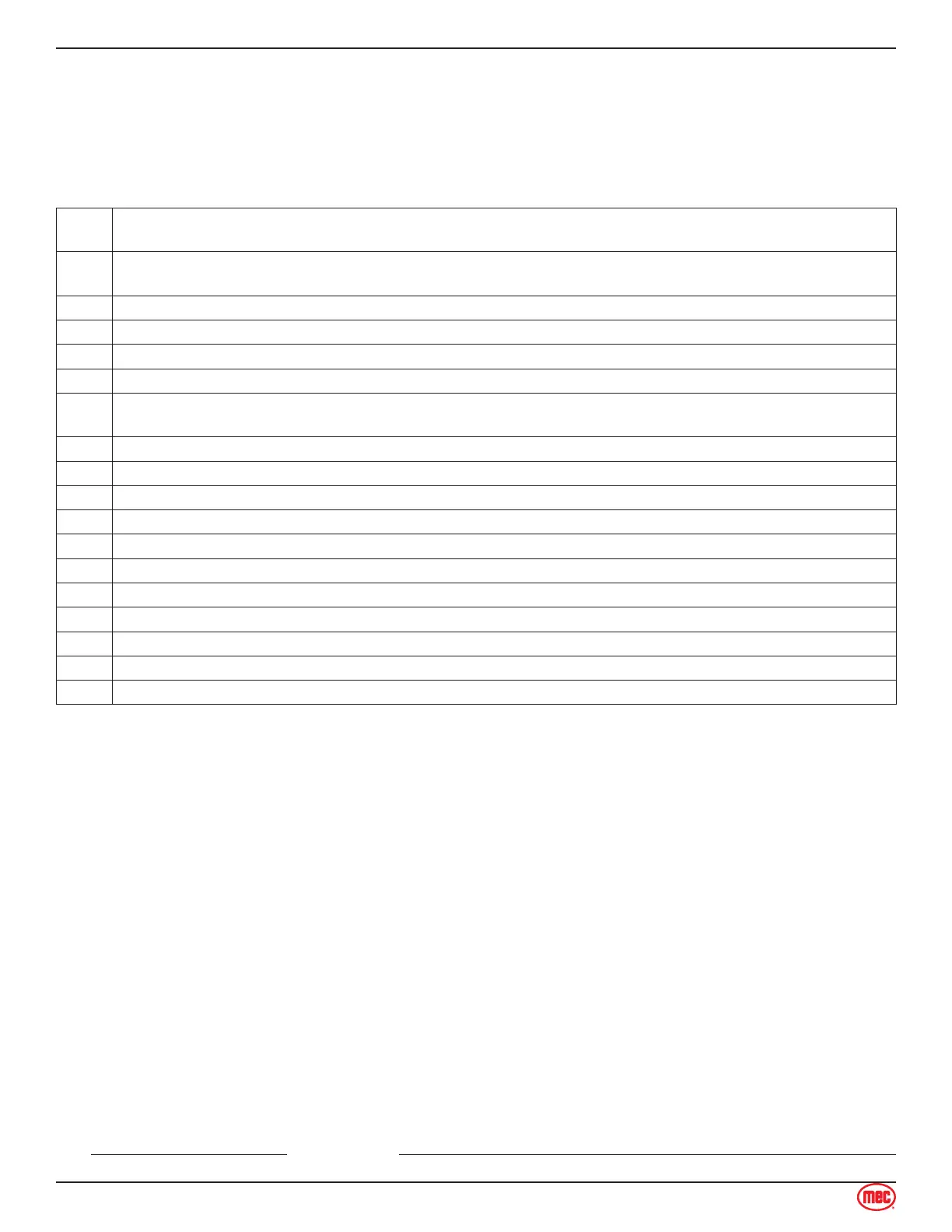

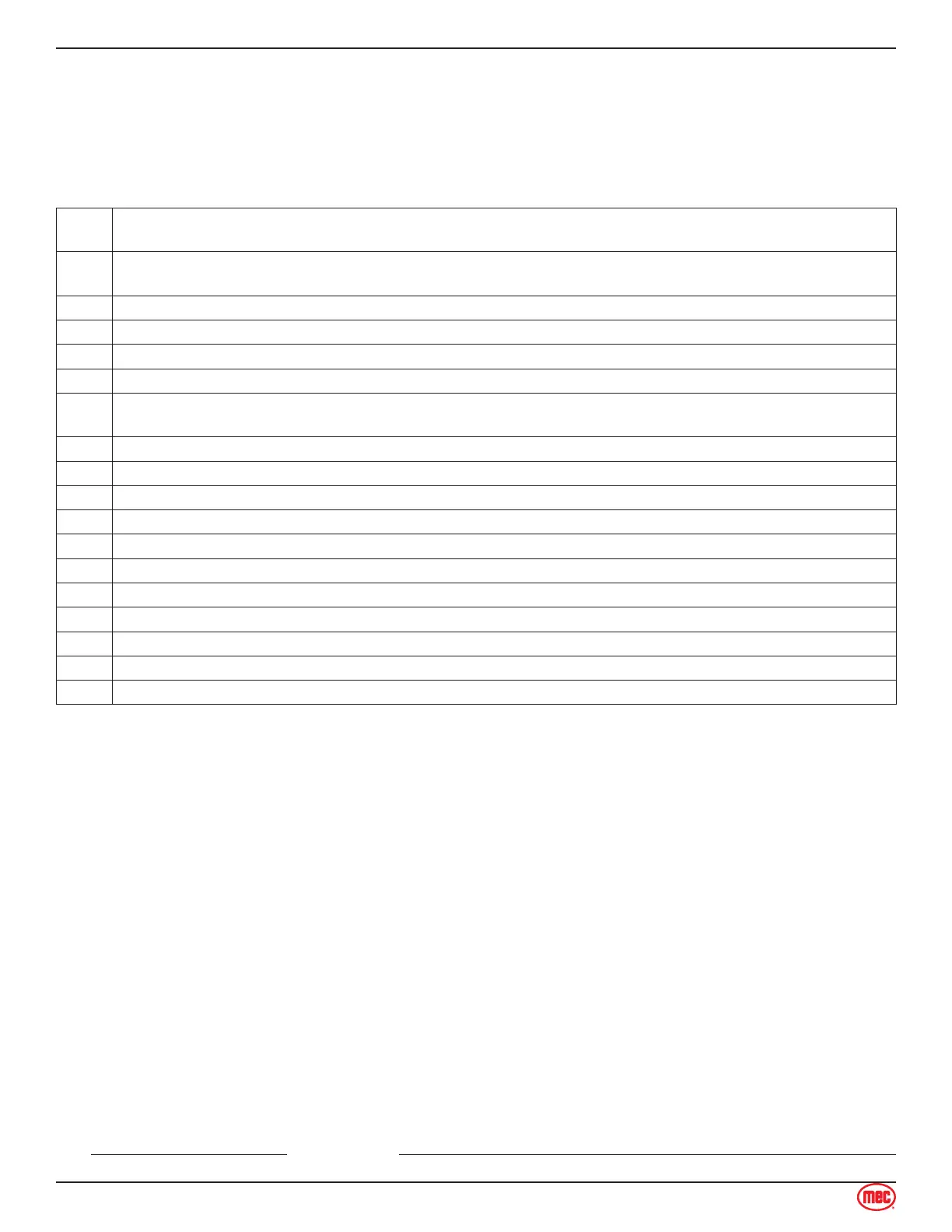

Pre-Start Inspection Checklist

The operator must conduct a Pre-Start Inspection of the machine before each work shift.

DO NOT use a damaged or malfunctioning machine.

Check that the operator’s manual and manual of responsibilities are in the storage container located on the

platform.

Perform a visual inspection of all machine components. Look for missing parts; torn or loose hoses;

hydraulic uid leaks; loose, torn or disconnected wires; damaged tires; etc.

Check all structural components of the machine for cracked welds, corrosion and collision damage.

Check the security and condition of the lanyard attachment points.

Check all controls for any damage and proper function.

Check all hoses and the cables for worn or chafed areas.

Check the platform rails and sliding mid-rail entries for damage or modication. Check the swing gate for

proper operation and latching.

Check that all warning and instructional decals are legible and secure.

Check the tires for damage.

Check the tire pressure (not required for foam lled tires).

All structural components, pins and fasteners are present and properly tightened.

Check for uid leaks.

Check hydraulic uid level (check with platform fully lowered).

Check engine oil level.

Check engine coolant level at overow bottle.

Check fuel tank level.

Secure all covers, panels and hoods.

Ensure that all gates are properly closed and secured before operating the machine.

Date Inspected By

Loading...

Loading...