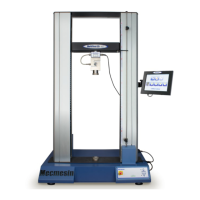

Mecmesin MultiTest-x manual

41

Appendix 4 – Technical Details

The state-of-art electronics built into MultiTest-x testing machines utilises a 32 bit

microprocessor delivering fast, accurate data acquisition together with automatic

control of product testing procedures.

Historically motorised tension/compression testers for quality control evaluation of

manufactured products have been based upon force gauges and test stands with

potentiometer controls (‘open loop’ control). The MultiTest-x range features both

automatic PID control and sophisticated measurements/analyses without the need for

a dedicated computer.

The digital control electronics consists of inputs for force and position measurement

plus limit switches for over-travel protection. A 24 bit (1 part in 16777216) A/D

converter provides high force resolution and accuracy (±0.25% FSD), while a high

accuracy rotary encoder measures position changes as small as 0.01mm. The control

output connects to an integral solid state motor amplifier that controls machine

movement. The PID algorithm, includes user-definable (factory preset) control

parameters, ensuring precise control of speed in both directions.

Control can be Monotonic, Dual Segment or Cyclic (see [1], [3], [3]) with the speeds

programmed into memory ahead of time and recalled whenever that test is to be run.

Monotonic control is a single speed test from beginning to end and can be either in

the pull (tensile) or push (compression) direction. On traditional product testing

machines, the control is via a potentiometer (open loop) and there is no automatic

facility for correcting the speed fall off. On the MultiTest-x, as the force increases, the

speed will not drop off, the PID control algorithm corrects automatically keeps the

speed constant, even up to the capacity of the testing machine. The test will stop

upon: specimen break, local overload, reaching a limit stop, test completion, pressing

[Stop/BK SP] button, or pressing the [Emergency Stop] button.

Dual Segment control provides a means of more complex control including a true hold

force feature, and

Cyclic control provides the means to cycle between either two load values or two

position values from to 1 – 999 times.

Appendix 5 – Tutorials

Commands available for developing test procedures. (see [1], [3], [3], [1]) and test

calculations (see [1], [3], [2], [1]) are listed in Section 1. In this section some simple

Loading...

Loading...