1. GENERAL

1.1 Scope of the Manual

This instruction manual contains important information

regarding the installation, operation and maintenance of

the Valvcon ADC-Series electric actuator. Please read these

instructions carefully and save them for future reference.

1.2 Actuator Markings

WARNING

AS THE USE OF THE ACTUATOR IS APPLICATION SPECIFIC, A

NUMBER OF FACTORS SHOULD BE TAKEN INTO ACCOUNT WHEN

SELECTING AN ACTUATOR FOR A GIVEN APPLICATION. THEREFORE,

SOME OF THE SITUATIONS IN WHICH THE ACTUATORS ARE USED

ARE OUTSIDE THE SCOPE OF THIS MANUAL.

IF YOU HAVE ANY QUESTIONS CONCERNING THE USE, APPLICATION

OR COMPATIBILITY OF THE ACTUATOR WITH THE INTENDED

SERVICE, CONTACT METSO FOR MORE INFORMATION.

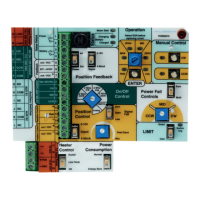

The actuator has an identification label attached to the base

casting (see Figure 1).

(1) (2) (7) (8) (9)

(3) (6) (5) (4)

MODEL# LADCWX1000U2-UP

SERIAL #

DUTY CYCLE 100%

SEAL ALL CONDUITS WITHIN 18"

CLASS I, DIV. I, GR. C & D;

CLASS II, DIV I, GR. E, F & G; CLASS III.

ENCLOSURE TYPE 4/4X IP66

V12345678

TORQUE 1000 LB-IN

0575

AMBIENT TEMP. -20 TO +66°C

I4800SEE MANUAL IMO-

230VAC

0.6 A

15 SEC

115VAC

0.9 A

15 SEC

24VAC

3.5 A

15 SEC

24VDC

2.4 A

14 SEC

12VDC

4.0 A

21 SEC

METSO AUTOMATION 44 BOWDITCH DRIVE SHREWSBURY, MA 01545 USA 1-508-595-5083

WARNING: DO NOT OPEN WHILE ENERGIZED OR WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT

VOLTAGE

CURRENT

STROKE TIME 90°

MC# 167265

Sira 13ATEX1166X

II2G Ex d IIB T6 Gb

IECEx CSA 14.0057X

®

Figure 1 Identification Plate

Identification label markings:

1. Model number

2. Serial number

3. Maximum output torque

4. Voltage

5. Current draw (full-load running)

6. Cycle time

7. Duty cycle

8. Applicable manual

9. Certifications marking

1.3 Safety Precautions

WARNING

DO NOT EXCEED THE ACTUATOR PERFORMANCE LIMITATIONS!

EXCEEDING THE TORQUE LIMITATIONS MARKED ON THE ACTUATOR

IDENTIFICATION LABEL MAY CAUSE DAMAGE TO THE ACTUATOR

AND/OR FINAL DRIVE ELEMENT.

WARNING

DO NOT EXCEED THE ACTUATOR ELECTRICAL LIMITATIONS!

EXCEEDING THE ELECTRICAL LIMITATIONS MARKED ON THE

ACTUATOR IDENTIFICATION LABEL MAY CAUSE DAMAGE TO THE

ACTUATOR AND/OR PERSONAL INJURY.

WARNING

BEWARE OF MOVEMENT OF THE FINAL DRIVE ELEMENT AND ANY

LINKAGE BETWEEN IT AND THE ACTUATOR!

KEEP HANDS, OTHER PARTS OF THE BODY, TOOLS AND OTHER

OBJECTS OUT OF THE WAY OF MOVING PARTS. FAILURE TO DO THIS

MAY RESULT IN DAMAGE OR PERSONAL INJURY!

2. TRANSPORTATION AND STORAGE

Check the actuator and any accompanying devices for any

damage that may have occurred during transport.

Store the actuator carefully. Storage indoors in a dry place

is recommended.

Move the actuator to its intended location just before

installation.

The actuator is usually shipped in the full clockwise,

(typically closed) position.

If the actuator(s) will be stored for a period longer than 90

days, follow the recommendations in IMO-S2 to maintain

the actuator’s integrity.

3. GENERAL INSTALLATION

INFORMATION

3.1 Description of ADC-Series Universal

Control Actuators (with Optional

Battery Back-Up)

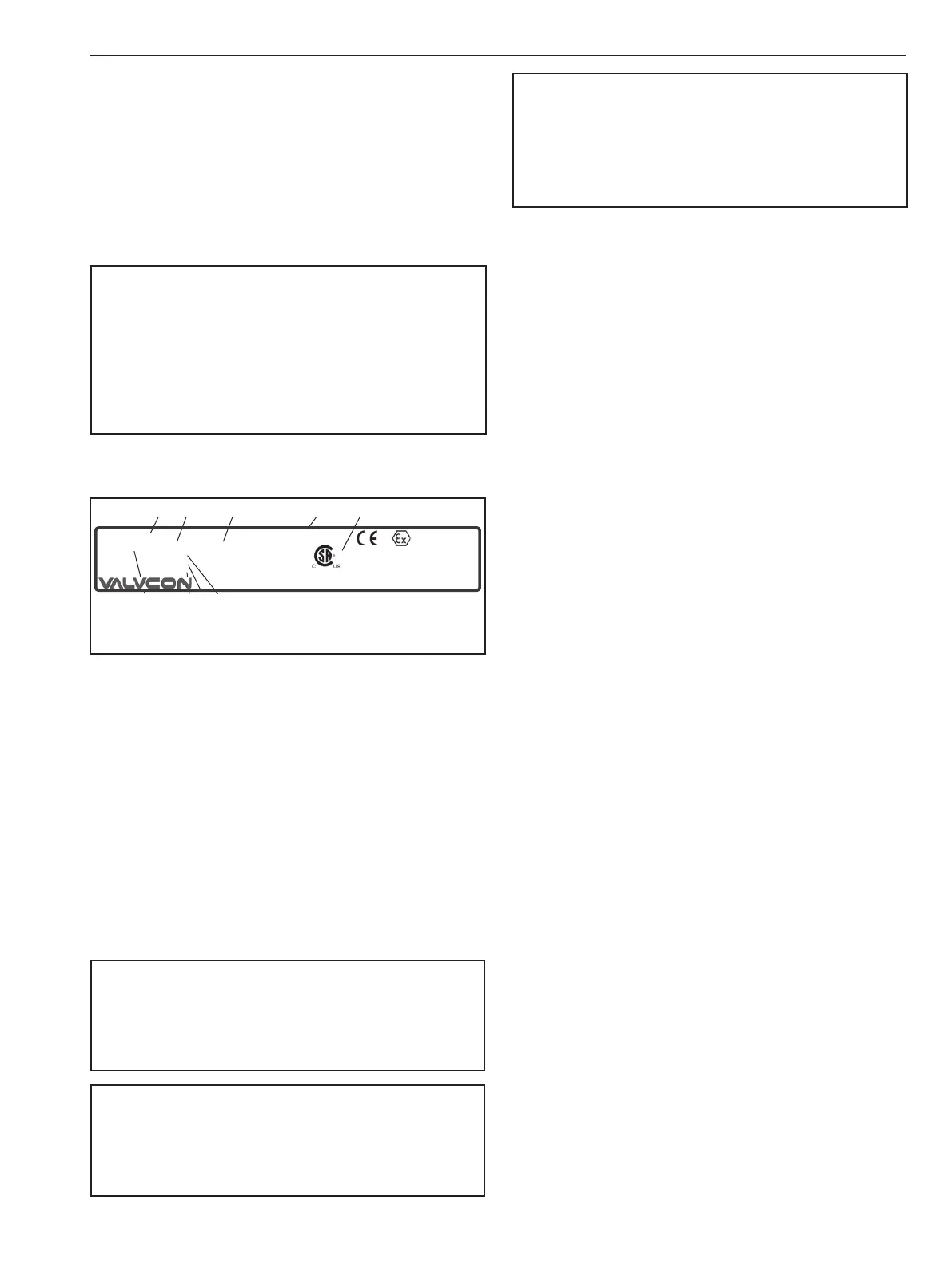

The ADC-Series consists of two different sized enclosures

that cover different torque ranges. Model codes that start

with “ADC” indicate the standard enclosure and a torque

rating in the range from 150 to 600 in•lbs. “LADC” designates

the larger enclosure and a torque rating in the range from

1000 to 3000 in•lbs.

The ADC-Series Actuators provide an optional internal

battery pack to power the actuator in the event of a loss

of external power. Actuators with battery back-up are

identified in the model code by either a “UL2”, “UL3”,

“UL4”, “UL5”, “UL6” or “UL7”. The “UL2”, “UL4” and “UL6”

options are applicable in a standard ADC enclosure and

the “UL3”, “UL5”and “UL7” options are applicable in a LADC

enclosure. The “UL4” and “UL5” options are factory-set for

180° operation with the MID position factory set at 90°;

and the “UL6” and “UL7” options are factory-set for 270°

operation.

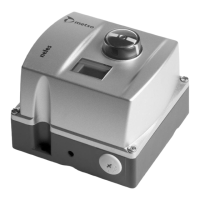

The ADC-Series Actuators’ base electronic package consists

of two separate boards; P/N VCB00010 Universal Control

Board and the Switching Power Supply allowing for the

choice of 115VAC, 230VAC, 12VDC, 24VDC or 24VAC

actuator power.

IMO 6/18

IMO-I4900 EN 3

Loading...

Loading...