1-800-325-9103

9100RT - 33 - www.meyermfg.com

8.0 MAINTENANCE

8.1 LUBRICATION

NOTE: Use a grease type that is composed of a high quality lithium complex or better, unless otherwise stated.

We recommend using a #1 grade in colder temperatures or a #2 grade in warmer temperatures.

DAILY or every 8-10 loads:

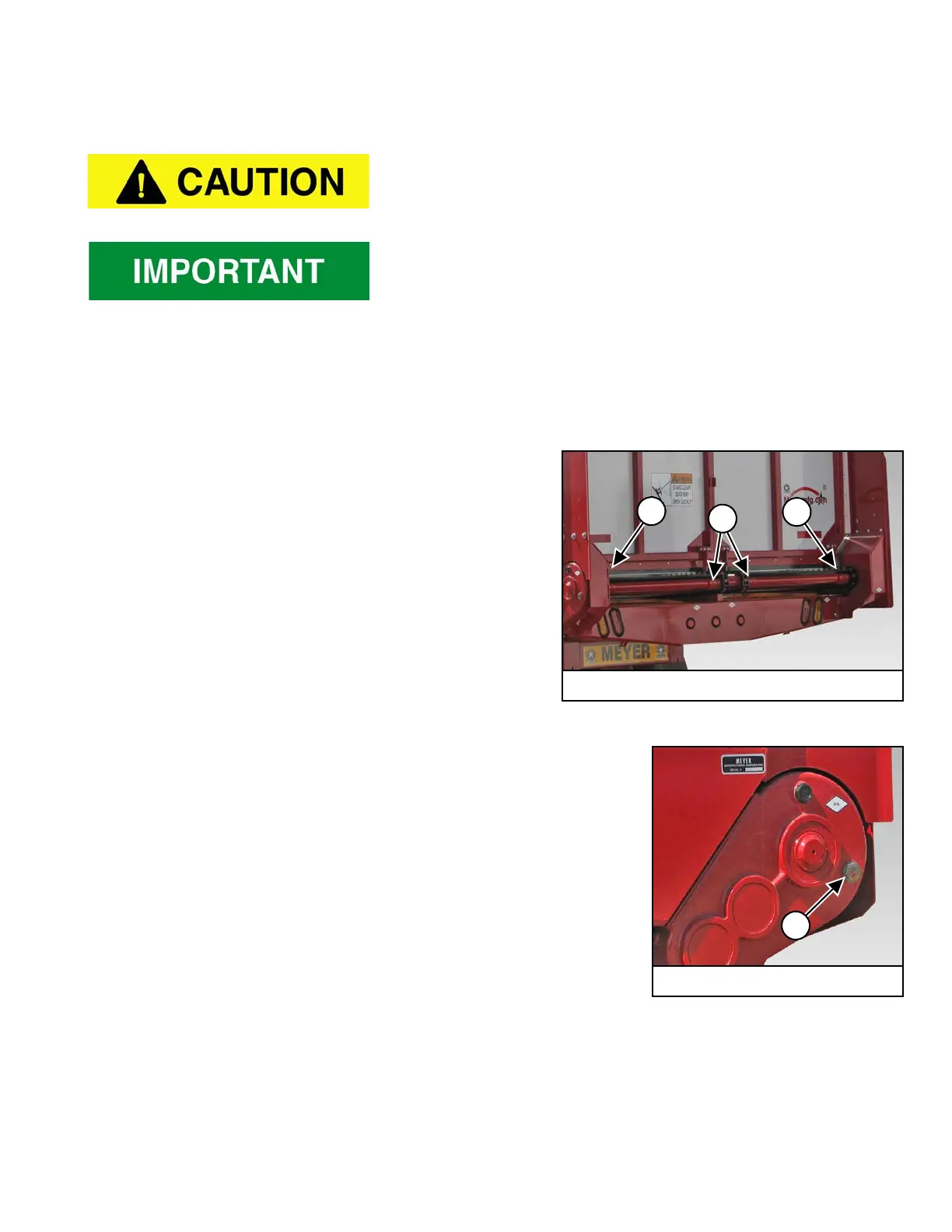

• Grease the four (4) main apron bearings (Item 1).

• Apply oil to the apron chains and inspect all forage box

components for wear or damage. Repair and replace

components as necessary.

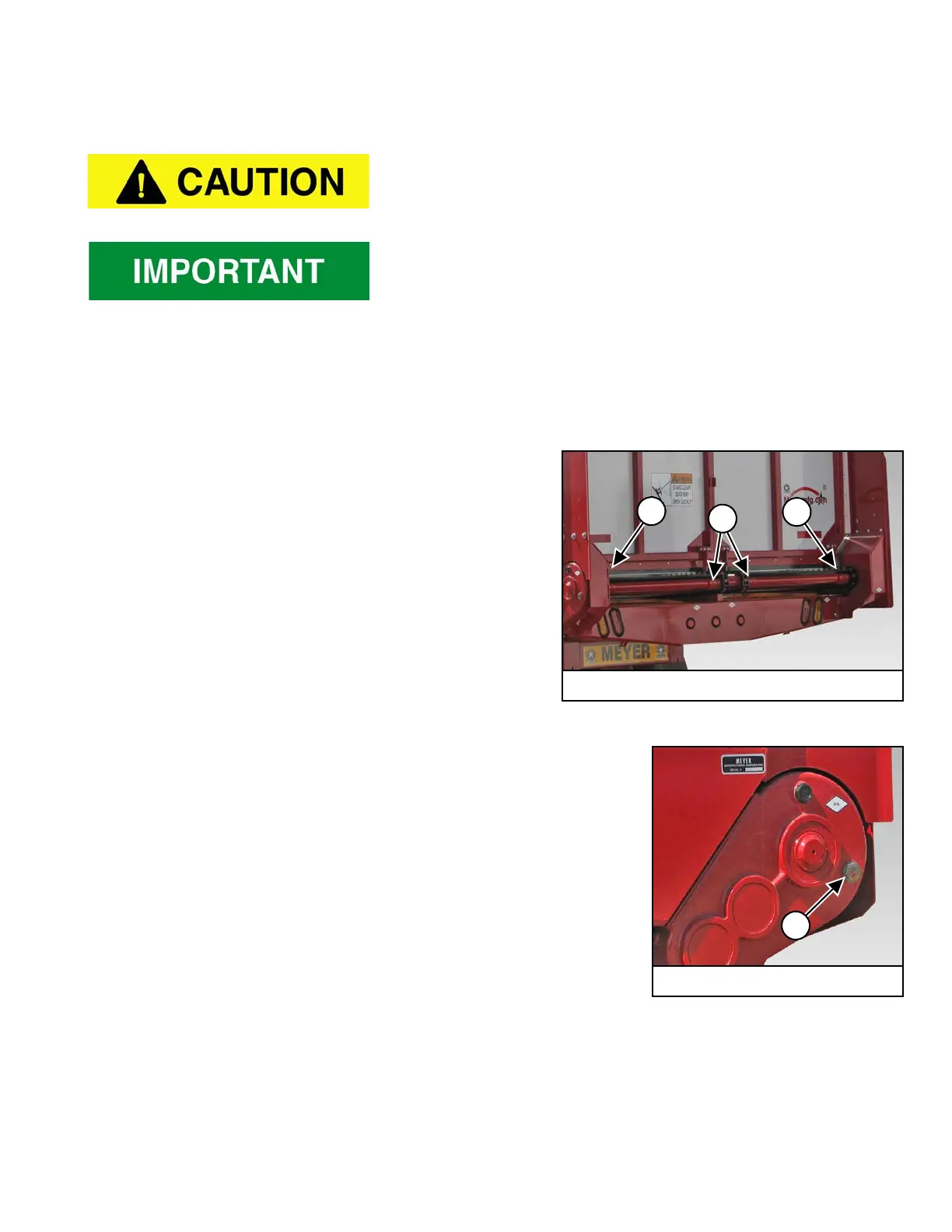

• Using the visual indicator on the gearbox, check gear lube in the gear box.

The oil level should be at the top of the sight glass when parked on level

ground.

Remove the plug (Item 2). Gear lube level should be at the bottom of the plug

hole and flowing out. Add EP 80-90 gear lube as needed (Lighter oil may be

used in temperatures lower than 20° F.).

Shutoff and lockout power before performing machine service,

adjusting, maintaining, or clearing an obstruction from this machine.

Refer to section 5.3 SHUTOFF & LOCKOUT POWER.

Fluid such as hydraulic fluid, grease, etc. must be disposed of in an

environmentally safe manner. Some regulations require that certain

spills and leaks on the ground must be cleaned in a specific manner.

See local, state and federal regulations for the correct disposal.

Main Apron Bearing Lubrication Locations

Loading...

Loading...