ELECTRICAL

Jammed starter pinion

In the event of the starter pinion becoming jammed in mesh with the flywheel,

it

can

usually be freed by turning the starter armatu re with a spanner applied

to the shaft extension at the commutator end.

Windshield wiper

Should it be necessary to reposition a wiper arm on the spindle, the

arm

can be

withdrawn when the small spring clip is held clear of the retaining groove.

Replace the

arm

in the required position and pu h it

hard

down

onto

the spindle

until it is secured in position by the retaining clip.

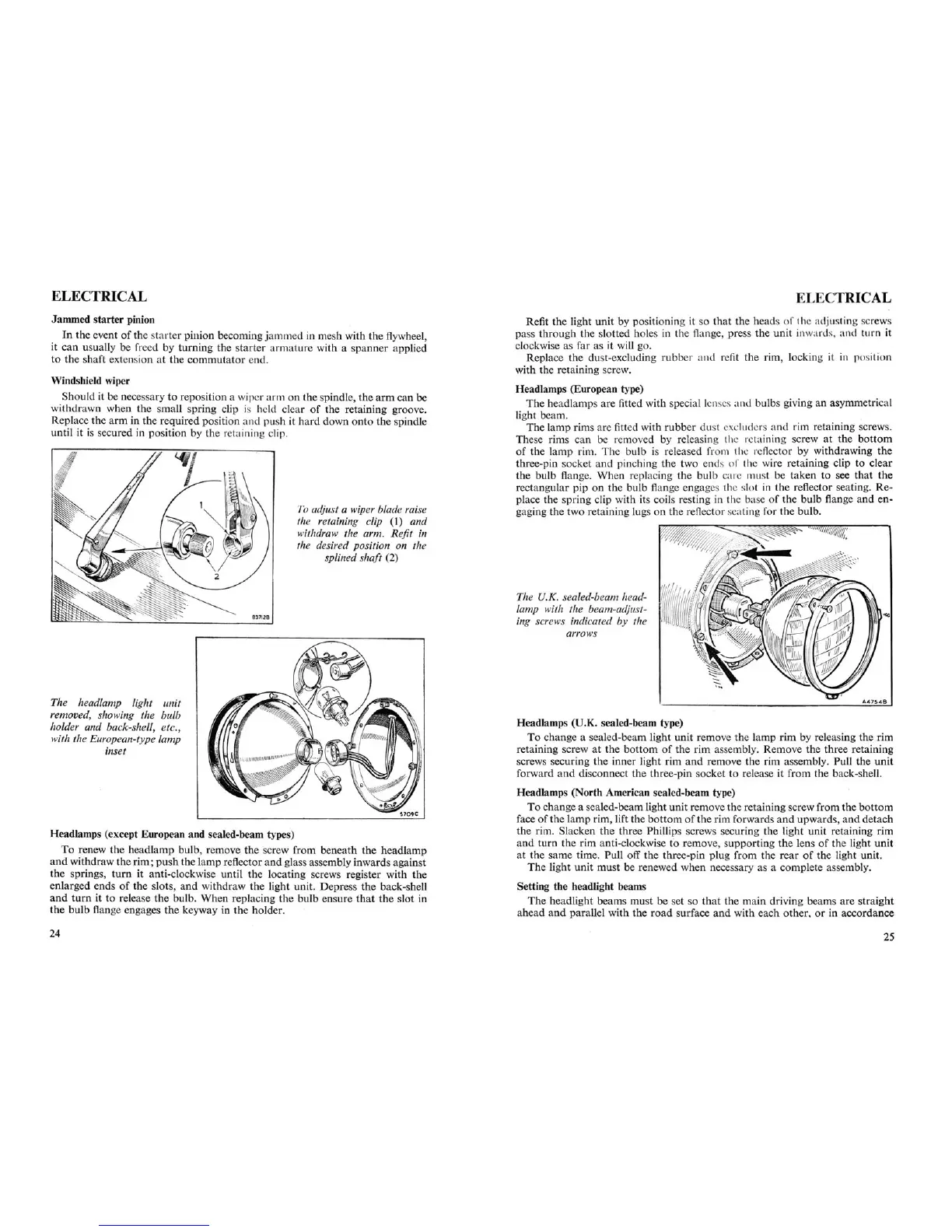

To adjust a wiper blade raise

the retaining clip

(1) and

withdraw the arm. Refit in

the desired position on the

splined shaft (2)

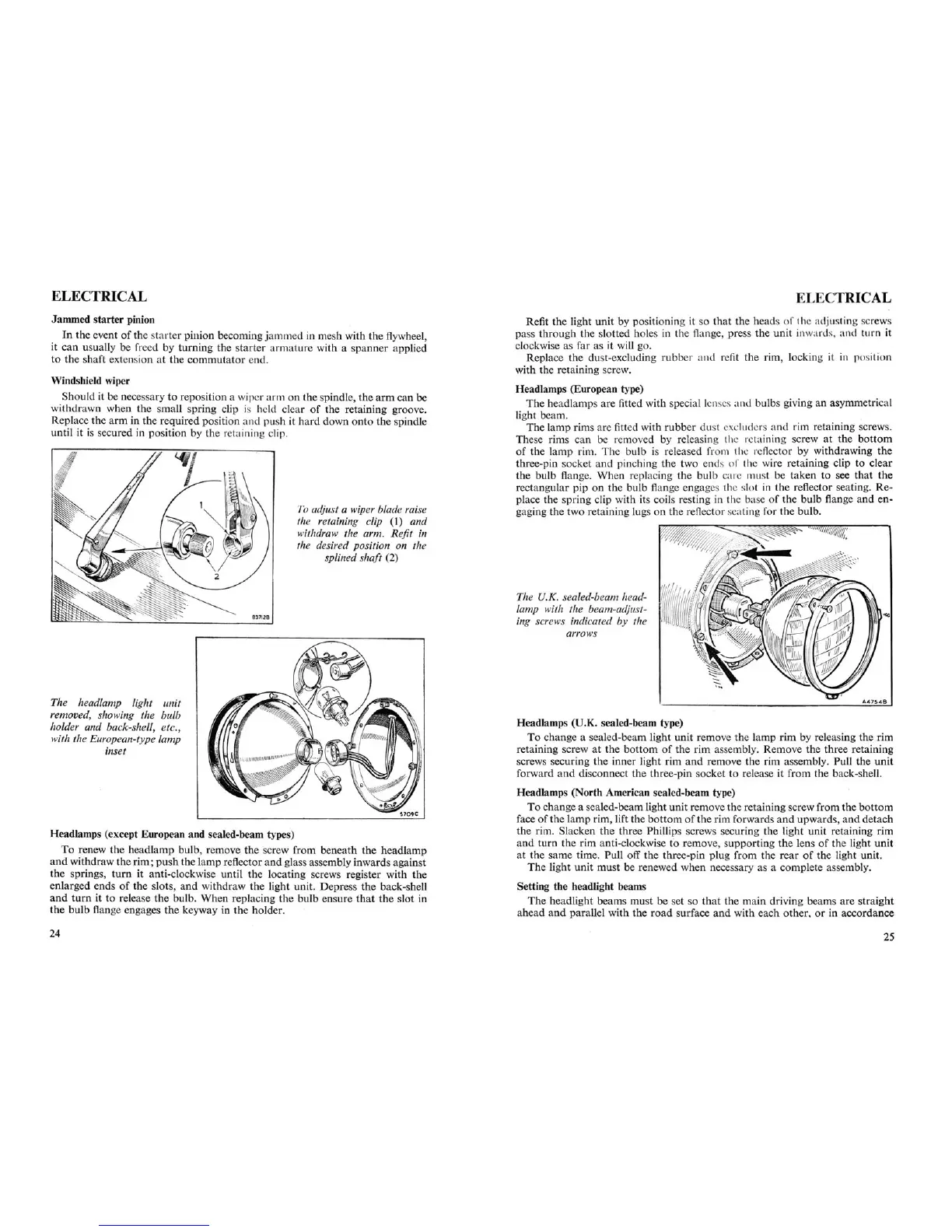

The headlamp light unit

removed, showing the bulb

holder and back-shell, etc.,

with the European-type lamp

inset

Headlamps (except European and sealed-beam types)

To renew the headlamp bulb, remove the screw from beneath the headlamp

and

withdraw the rim;

push

the lamp reflector

and

glass assembly inwards against

the springs,

turn

it anti-clockwise until the locating screws register with the

enlarged ends of the slots,

and

withdraw the light unit. Depress the back-shell

and

turn

It to release the bulb. When

replacing

the bulb ensure

that

the slot in

the bulb flange engages the keyway in the holder.

24

CTRICAL

Refit the light unit by positioning it so

that

the heads of the adjusting screws

pass through the slotted holes in the flange, press the unit inwards, and tur n it

clockwise as far as it will go.

Replace the dust-excluding rubber and refit the rim, locking it in positi n

with the retaining screw.

Headlamps (European type)

The headlamps are fitted with special lenses and bulbs giving an asymmetrical

light beam.

The lamp rims are fitted with rubber dust excluders and rim retaining screws.

These rims can be removed by releasing the retaining screw at the

bottom

of the lamp rim. The bulb is released from the reflector by withdrawing the

three-pin socket and pinching the two ends of the wire retaining clip to clear

the bulb flange. When replacing the bulb care must be taken to see that the

rectangular pip on the bulb flange engages the slot in the reflector seating. Re-

place the spring clip with its coils resting in the base of the bulb flange

and

en-

gaging the two retaining lugs on the reflector seating for the bulb .

The U.K. sealed-beam head-

lamp with the beam-adjust-

ing screws indicated by the

arrows

Headlamps (U.K. sealed-beam type)

To change a sealed-beam light unit remove the lamp rim by releasing the rim

retaining screw at the bo

ttom

of the rim assembly. Remove the three retaining

screws securing the inner light rim

and

remove the rim assembly. Pull the unit

forward

and

disconnect the three-pin socket to release it from the back-shell.

Headlamps (North American sealed-beam type)

To change a sealed-beam light unit remove the retaining screw from the

bottom

face of the lamp rim, lift the

bottom

of the rim forwards

and

upwards,

and

detach

the rim. Slacken the three Phillips screws securing the light unit retaining rim

and

turn

the rim anti-clockwise to remove, supporting the lens of the light unit

at the same time. Pull off the three-pin plug from the rear

of

the light unit.

The light unit must be renewed when necessary as a complete assembly.

Setting the headlight beams

The headlight beams must be set so

that

the main driving beams are straight

ahead

and

parallel with the

road

surface

and

with each other. or in accordance

25

Loading...

Loading...