EVERY 6,000

MILES

(10000 Km.)

EVERY 6,000 MIL

( 0000 Km.)

Front brakes

Inspect brake pads: if worn unequally, change over their operating positions.

This work should be carried

out

by an authorized Distributor/Dealer.

Sparking plugs

Remove the plugs

and

clean off all carbon depos it from the electrodes and

plug

thr

eads with a stiff brush dipped in p

ara

ffin (kerosene).

Check the plug gaps,

and

reset if necessary to the .recommended clearance

(see 'GENERAL DATA'). When resetting bend the side electrode only

-ne

ver

bend the centre electrode as this may split the insulator tip.

When refitting the plugs, make sure tlu.t the copper washers are not defective

in any way. If they have become worn and flattened, fit new ones to ensure

a gas-tight joint. Screw the plug down

by

hand

as far as possible, then use a

spanner for tightening only. Always lise a tubul ar box spanner to avoid possible

damage to the insulator,

and

do not under any circumstances use a movable

wrench. Never overtighten a plug, bu

t cnsure

that

a good

joint

is made between

the plug body, washer,

and

cylinder head.

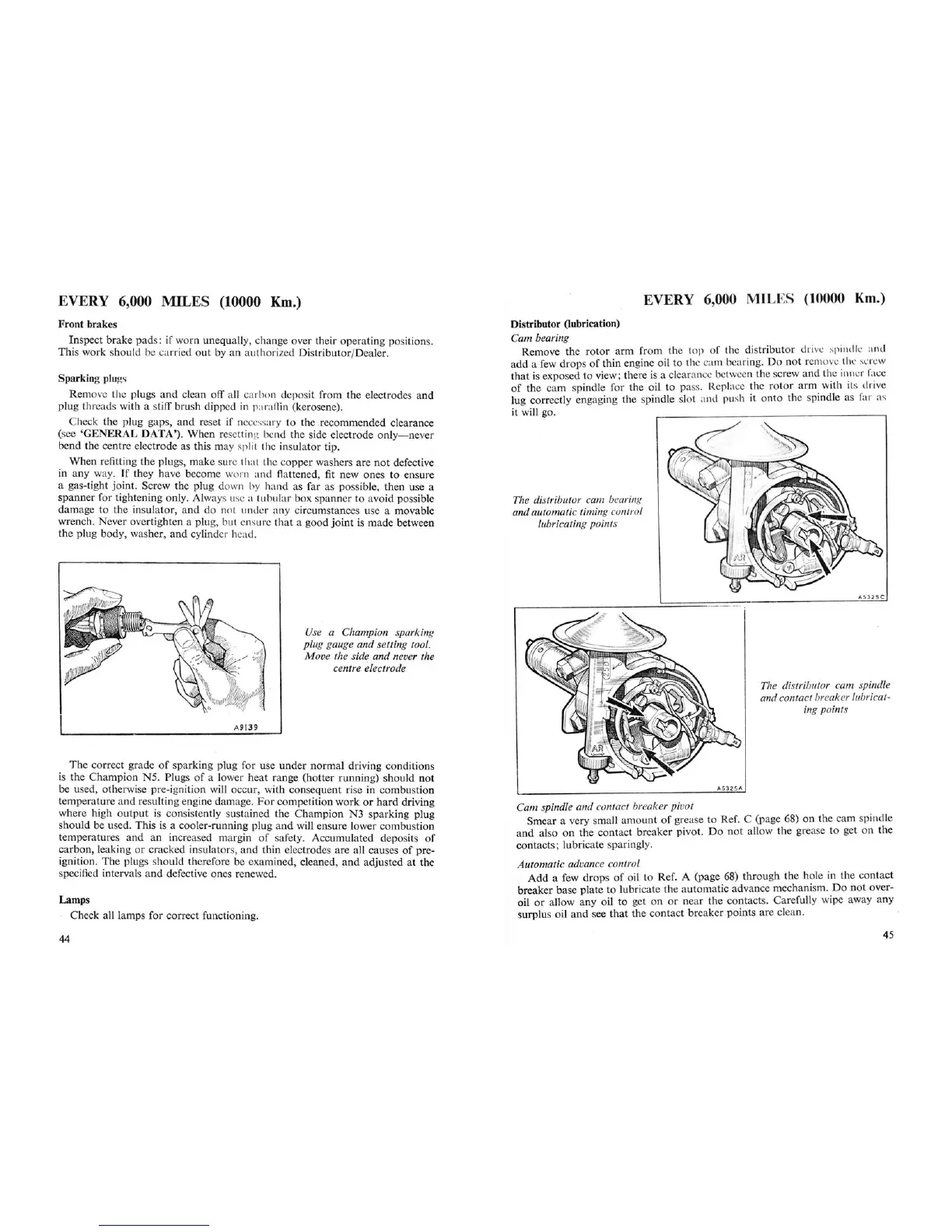

Use a Champion sparking

plug gauge and setting tool.

Mo ve the side and never the

centre electrode

A913 9

The correct grade of sp

ark

ing plug for use

under

normal

driving conditions

is the Champion N5. Plugs of a lower

heat

range (hotter running) should not

be used, otherwise pre-ignition will occur, with consequent rise in combustion

temperature

and

resulting engine damage. For competition work or

har

d driving

where high

output

is consistently sustained the Champion N3 sparking plug

should be used. This is a cooler-running plug

and

will ensure lower combustion

temperatures,

and

an increased margin of safety. Accumulated deposits of

carbon, leaking or cracked insulators,

and

thin electrodes are all causes of pre-

ignition. The plugs should therefore be examined, cleaned,

and

adjusted at the

specified intervals

and

defective ones renewed.

Lamps

Check all lamps for correct functioning.

44

Distributor (lubrication)

Cam bearing

Remove the rotor arm from the top of the distributor drive spindle and

add a few drops of thin engine oil to the cam bearing.

Do

not

remove .lht' s

.

~

.

'w

that

is exposed to view; there is a clearance between the screw

and

t~

e

In.

ncr

f

~~

~c

of the cam spindle for the oil to pass. Replace the rotor arm. with its driv

lug correctly engaging the spindle slot and push it

onto

the spindle as far as

it will go.

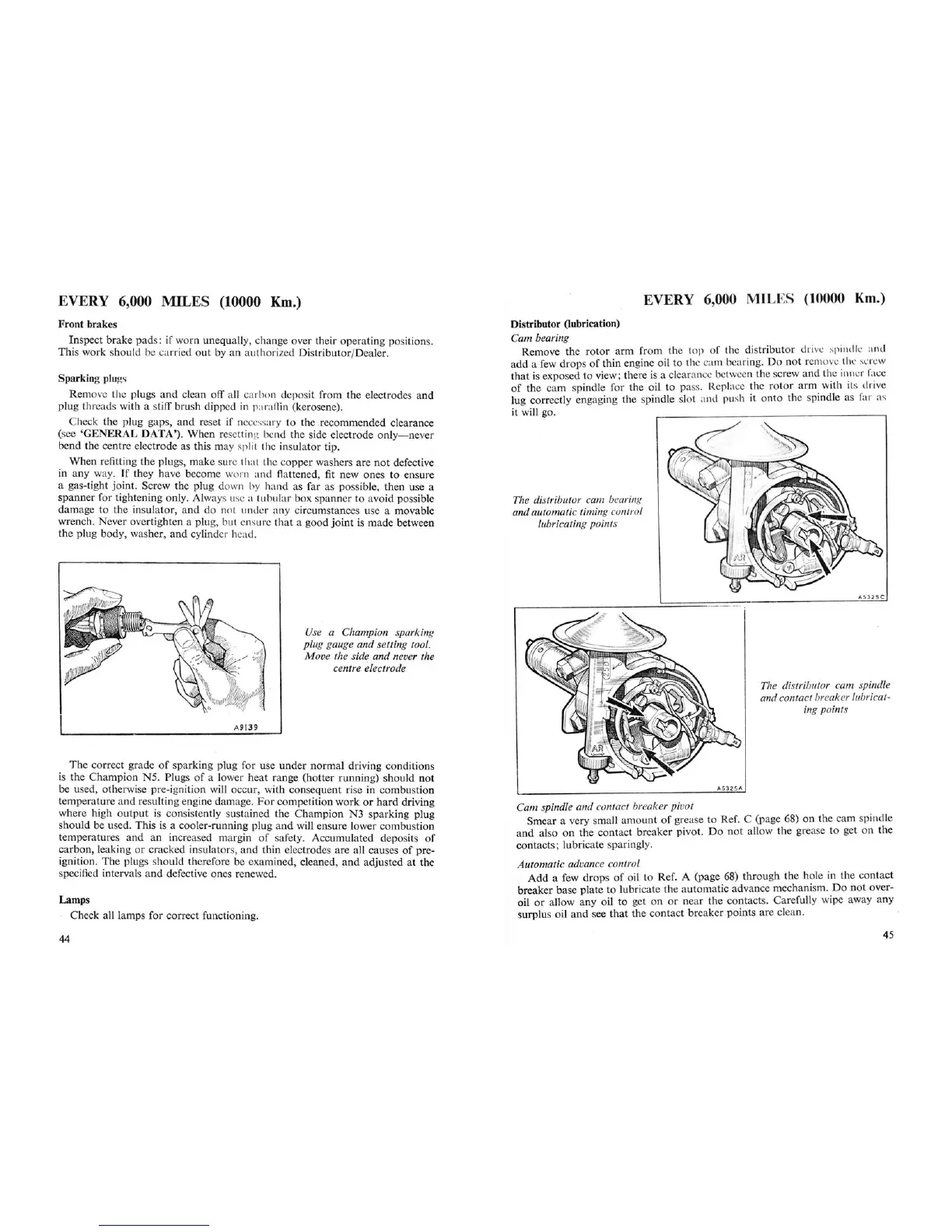

The distributor cam bearing

and automatic timing control

lubricating points

A

532

5 C

The distributor cam spindle

and contact breaker lubricat-

ing points

Cam spindle and contact breaker pivot

Smear a very small amo

unt

of

grease to Ref. C (page 68) on the cam spind le

and also on the contact breaker pivot.

Do

not

allow the grease to get on the

contacts;

lubr

icate sparingly.

Automatic advance control

Add a few drops of oil to

Ref

. A (page 68) through the hole in the contact

breaker base plate to lubricate the automatic advance

~e

ch!1r:

_ism

..

Do

not

over-

oil or allow any oil to get on or near the contacts. Carefully wipe away any

surplus oil

and

see

that

the contact breaker points are clean. .

45

Loading...

Loading...