m.)

A

42 79A

(

()OOO

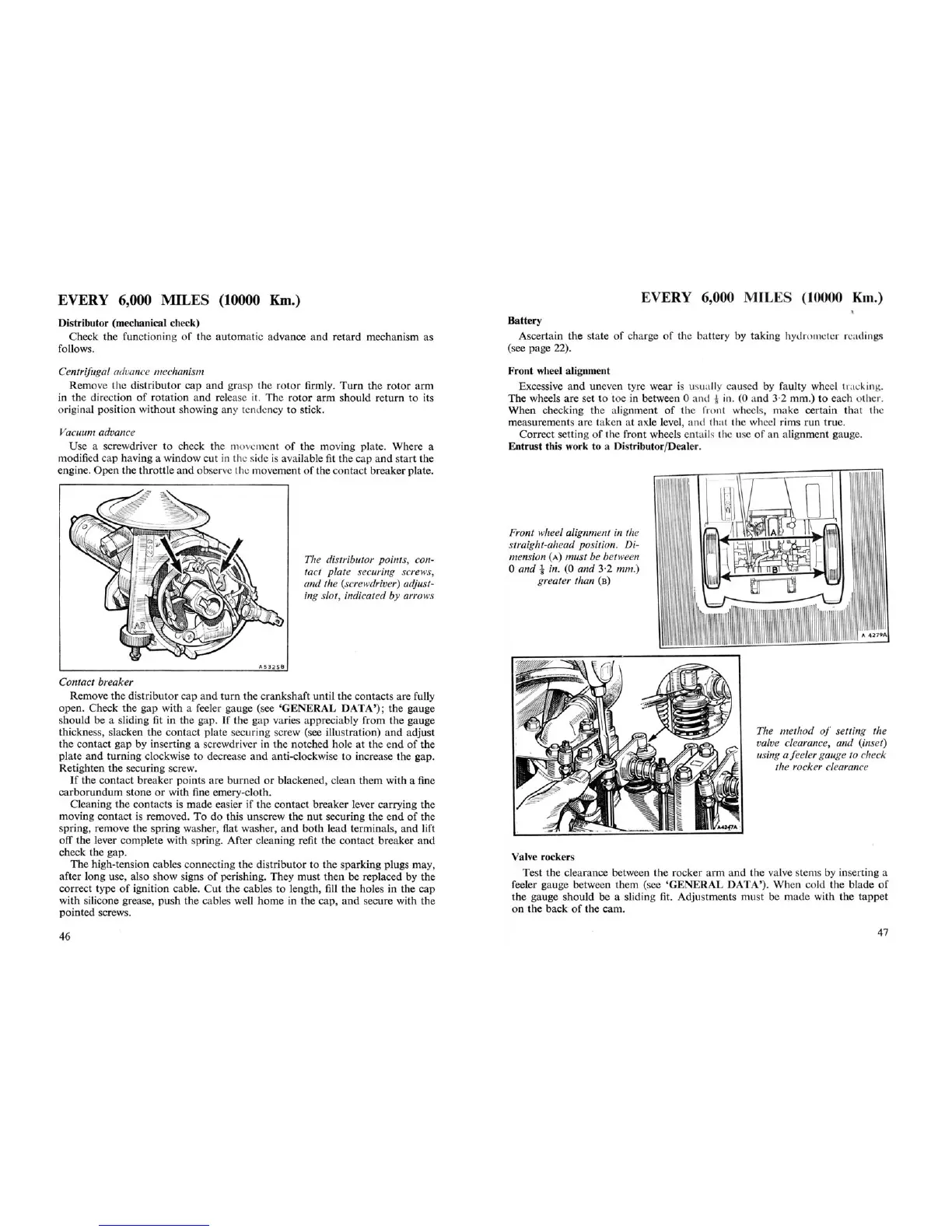

The method oj'

sett

ing the

valve clearance, and (inset)

using a feeler gauge to check

the rocker clearance

EVERY 6,000 M

Battery

Ascertain the state

of

charge of the battery by

tak

ing

hyd rometer

r 'a

Iii .

(see page 22).

Front wheel alignment

Excessive

and

uneven tyre wear is usually caused by faulty wheel

track

in .

The wheels are set to toe in between 0 and

*

in. (0

and

3'2

mm.) to each other.

When checking the alignment

of

the front wheels, make certain that the

measurements are taken at axle level, and that the wheel rims run true.

Correct setting

of

the front wheels entails the usc

of

an alignment gauge.

Entrust this work to a Distributor

/Deale

r.

Front wheel alignment in the

straight-ahead position. Di-

mension (A) must be

bet

ween

o

and

tin

.

(0

and

3·2

mm.)

greater than (B)

Valve rockers

Test the clearance between the rocker

arm

and

the valve stems by inserting a

feeler gauge between them (see

'GENE

RAL DATA'). When cold the blade of

the

gaU

ge

should

be a

sliding

fit.

AdjUstments

mU

st be made

with

the

tappet

on the back

of

the cam.

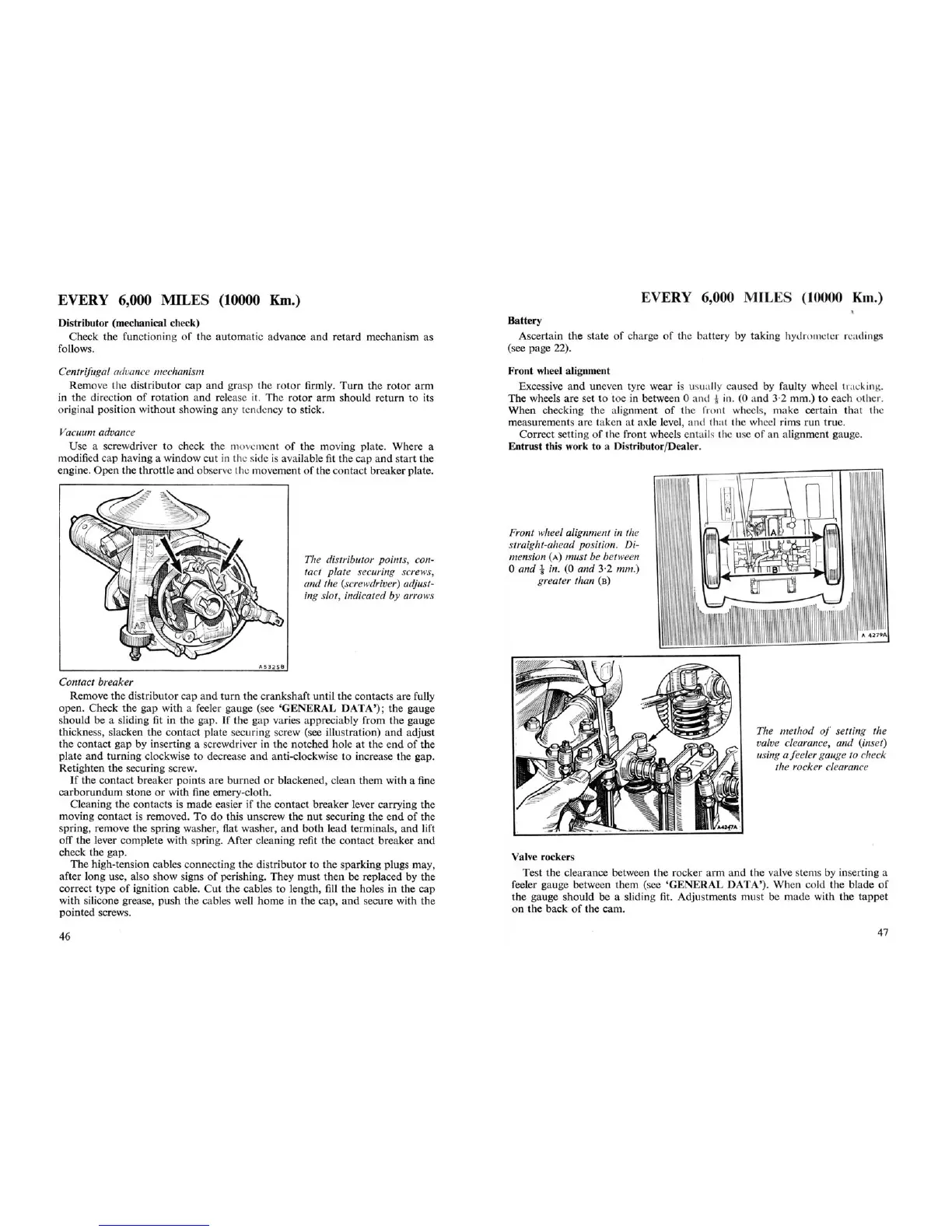

The distributor points, con-

tact

plat

e securing screws,

and the (screwdriver) adjust-

ing slot, indic

ate

d by arrows

A5

3258

Vacuum

ad

vance

Use a screwdriver to check the movcment

of

the moving plate. Where a

modified cap having a window cut in the side is available fit the cap

and

start

the

engine. Open the throttle

and

observe the movement

of

the contact breaker plate.

Centrifugal advance

mecbanism

Remove the distributor cap

and

grasp the

rotor

firmly.

Turn

the

rotor

arm

in the direction

of

rotation

and

release it. The rotor

arm

should return to its

original position without showing any tendency to stick.

Distributor (mechanical check)

Check the functioning

of

the

auto

matic advance

and

retard mechanism as

follows.

EVERY 6,000 MILES (10000

Km.)

Contact breaker

Remove the distributor cap

and

turn

the crankshaft until the contacts are fully

open. Check the gap with a feeler gauge (see 'GENERAL

DATA');

the gauge

should be a sliding fit in the gap.

If

the gap varies appreciably from the gauge

thickness, slacken the contact plate securing screw (see illustration)

and

adjust

the contact gap by inserting a screwdriver in the notched hole at the end

of

the

plate

and

turning clockwise to decrease

and

anti-clockwise to increase the gap,

Retighten the securing screw.

If

the contact breaker points

are

burned

or

blackened, clean them with a fine

carborundum stone or with fine emery-cloth.

Cleaning the contacts is

made

easier if the contact breaker lever carrying the

moving contact is removed. To do this unscrew the

nut

securing the

end

of

the

spring, remove the spring washer, flat washer,

and

both

lead terminals,

and

lift

off the lever complete with spring. After cleaning refit the contact breaker

and

check the gap.

The high-tension cables connecting the distributor to the sparking plugs may,

after long use, also show signs

of

perishing. They must then be replaced by the

correct type

of

ignition cable. Cut the cables to length, fill the holes in the cap

with silicone grease, push the cables well

home

in the cap,

and

secure with the

pointed screws.

46

47

Loading...

Loading...