MAINTENANCE SUMMARY

B

.M

.C. SEAT BE

6. Electrical

Check battery cell specific gravity readings

and

top

up to correct levels.

Lubricate dynamo bearing.

Check all lamps for correct functi oning.

7. L ubrication

Top up oil level in gearbox

and

rear axle.

Fit new oil filter element.

Change oil in engine.

Lubricate all grease nipples.

Lubricate steering rack

and

pinion.

8. Wheels and tyres

Check tyre pressures.

SUPP

L

EM

ENTARY

TOOL

KIT

To supplement the tool kit a roll containing the following is obtainable from

all Distributors.

Part

No

. 97H 524 should be quoted.

4 spanners:

-&

in. X i in. A.F.

1\-

in. x ! in. A.F.

1\ in. x

tin.

A.F

.

'*

in. x ! in.

A.F

.

I

pa

ir 6 in. pliers.

1 adjustable spanner (7 in.).

1 tommy-bar (I in. diameter).

1

tubula

r sp

ann

er (! in. x 1\ in.

A.F

.).

1 Phillips screwdriver.

54

Seat belts are available from B.M.C. Service Ltd. Fitting shou ld only 1 rri d

out

by an

autho

rized Distributor

/Dea

ler.

The complete seat belt is made up of two sections, both adjusta l

I ", whi .h,

when in use, are connected by a quick-action buckle. The end bracket (witl the

two holes) of the long belt is bolted to the wheel arch and the other cnd i

attached to the sill with the bolt supplied. The bracket on the

end

of the short

belt is bolted to the wearer's side of the propeller shaft tunnel. When

in lI SC

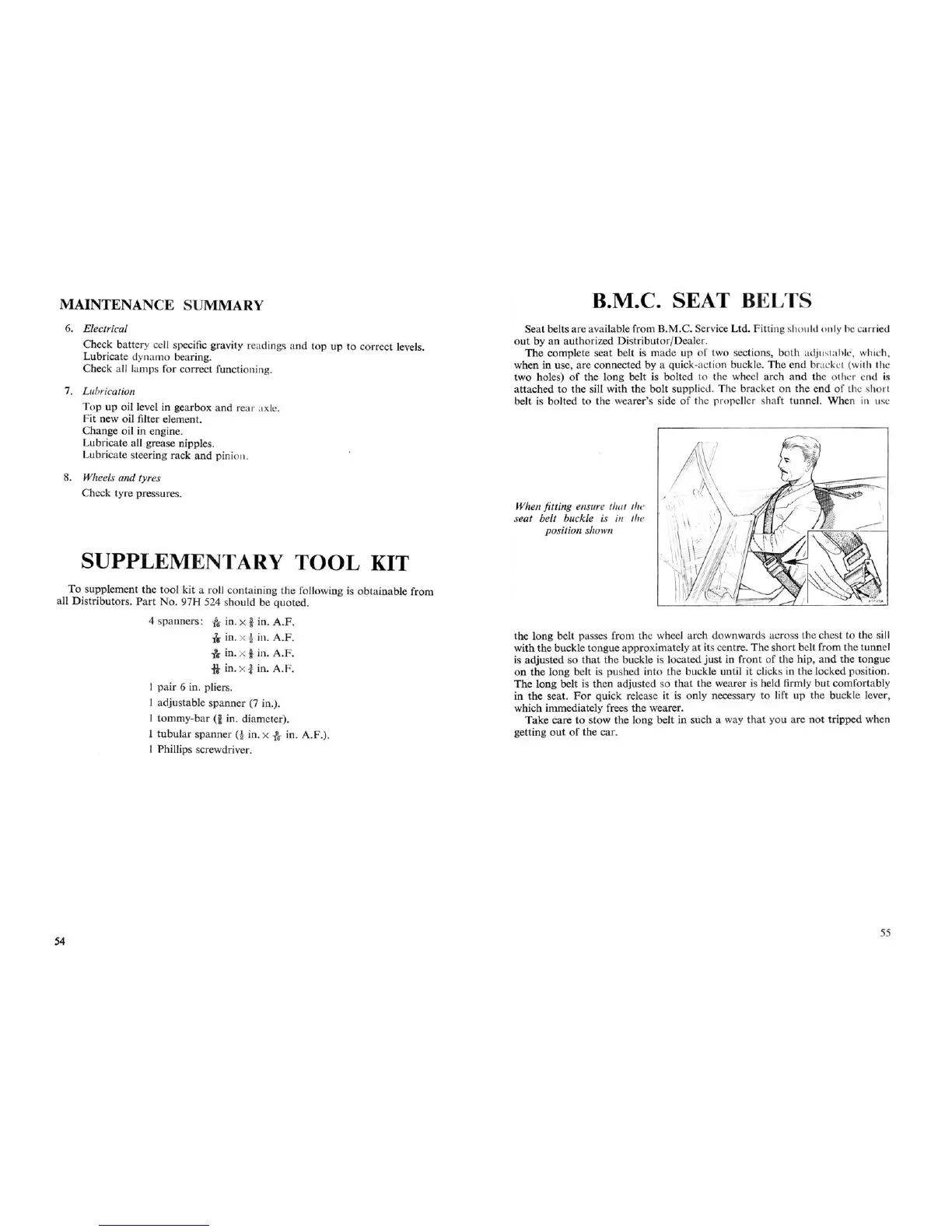

When fitting ensure that the

seat belt buckle is in the

position shown

the long belt passes from the wheel arch downwards across the chest to the sill

with the buckle tongue

appr

oximately at its centre. The short belt from the tunnel

is adjusted so

that

the buckle is located just in front of the hip, and the tongue

on the long belt is pushed into the buckle until it clicks in the locked position.

The long belt is then adjusted so

tha

t the wearer is held firmly

but

comfortably

in the seat.

For

quick release it is only necessary to lift up the buckle lever,

which immediately frees the wearer.

Take

care to stow the long belt in such a way

tha

t you are not tripped when

getting

out

of the car.

55

Loading...

Loading...