3: Operating Procedures

Portaflow 220 User Manual 21

(Issue 1.0)

With the system running in FLOW READING mode:

3.5.5 Adjusting the damping factor

By averaging-out the flow rate over several seconds, the Damping factor can be used to smooth out

rapid changes in flow rate to prevent wild fluctuations in the displayed flow value. It has a range of 1 to 199,

with a default setting of 10. With the system running in FLOW READNG mode:

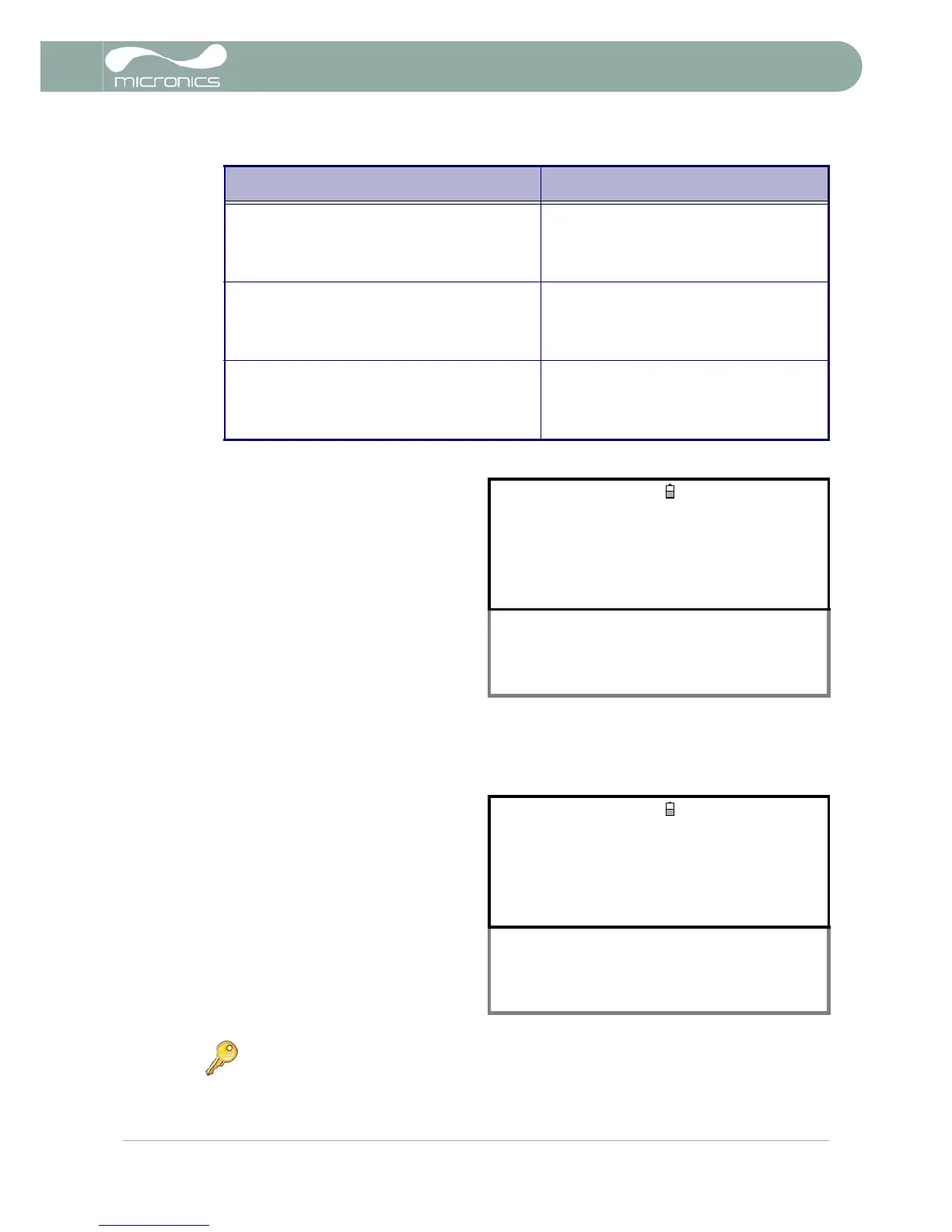

Drawn steel pipes:

• Fine planed, polished surface

• Plane surface

• Rough planed surface

0.01

Welded steel pipes, new:

• Long usage, cleaned

• Lightly and evenly rusted

• Heavily encrusted

0.1

Cast iron pipes:

• Bitumen lining

• New, without lining

• Rusted / Encrusted

1.0

1. Press the Options key to access the FLOW

READING OPTION screen shown.

2. Scroll down and select Roughness

factor.

3. Change the roughness factor according to

the pipe material and condition as described

above.

4. Press Enter to apply the change.

FLOW READING OPTION

DD-MM-YY HH:MM:SS

Data review

Zero Cutoff (m/s) : 0.00

Set zero flow (m/s) : 0.00

Damping (secs) : 10

Totaliser : Run

Reset +Total

Reset –Total

Calibration factor : 1.000

Roughness factor : 0.01

Diagnostics

Exit

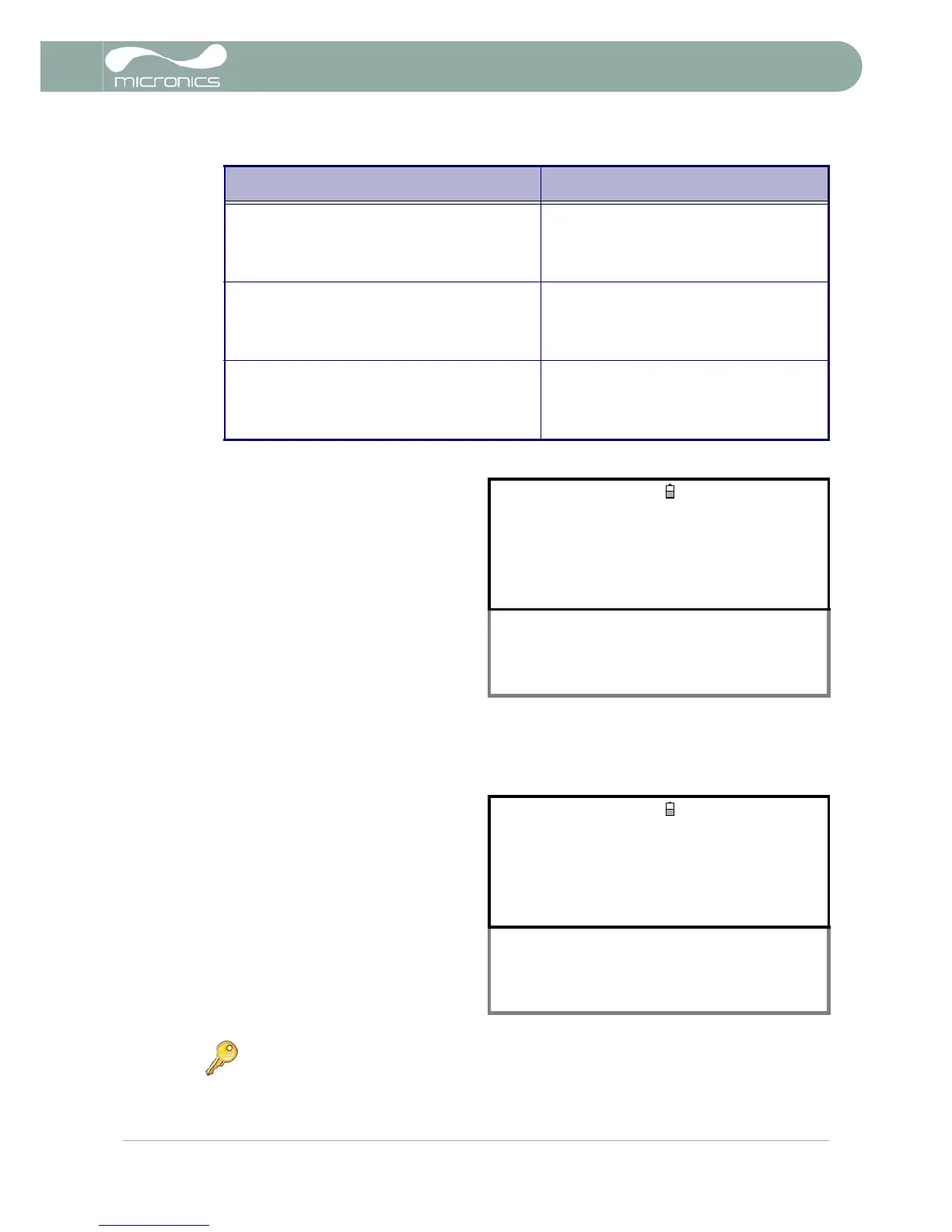

1. Press the Options key to access the FLOW

READING OPTION screen shown.

2. Scroll down and select Damping (secs).

3. Change the value of the Damping factor

as required to remove any unwanted display

fluctuations. Increasing the value applies a

greater smoothing affect.

4. Press Enter to apply the change.

FLOW READING OPTION

DD-MM-YY HH:MM:SS

Data review

Zero Cutoff (m/s) : 0.00

Set zero flow (m/s) : 0.00

Damping (secs) : 10

Totaliser : Run

Reset +Total

Reset –Total

Calibration factor : 1.000

Roughness factor : 0.01

Diagnostics

Exit

Key Point: If the damping factor is set too high the value displayed may appear

stable but it may exhibit large step changes when the value is updated.

Pipe Material Roughness Factor

Loading...

Loading...