Certified Drawing

IM 613 / Page 11 (Rev. 7/99)

The following commissioning procedures pertain to unit ventila-

tors equipped with the MicroTech Unit Ventilator Controller (UVC).

These procedures must be performed in addition to the mechanical

and electrical system commissioning procedures that are

outlined in the model-specific installation literature. Table 5

provides a listing of this literature.

Caution: Before power is applied to any unit, the pre-start

procedures in the model-specific installation literature must be

closely followed.

WARNING

ELECTRICAL SHOCK HAZARD! Could cause severe injury or death. Failure to bond the frame of this equipment to the

building electrical ground by use of the grounding terminal provided or other acceptable means may result in electrical shock.

Service must be performed only by qualified personnel.

A large part of the commissioning procedure is ensuring that the

unit ventilator operates according to its programmed sequence

of operation. The unit ventilator sequences of operation are

described in the program-specific literature listed in Table 6.

Commissioning

Unit Ventilator Installation & Maintenance

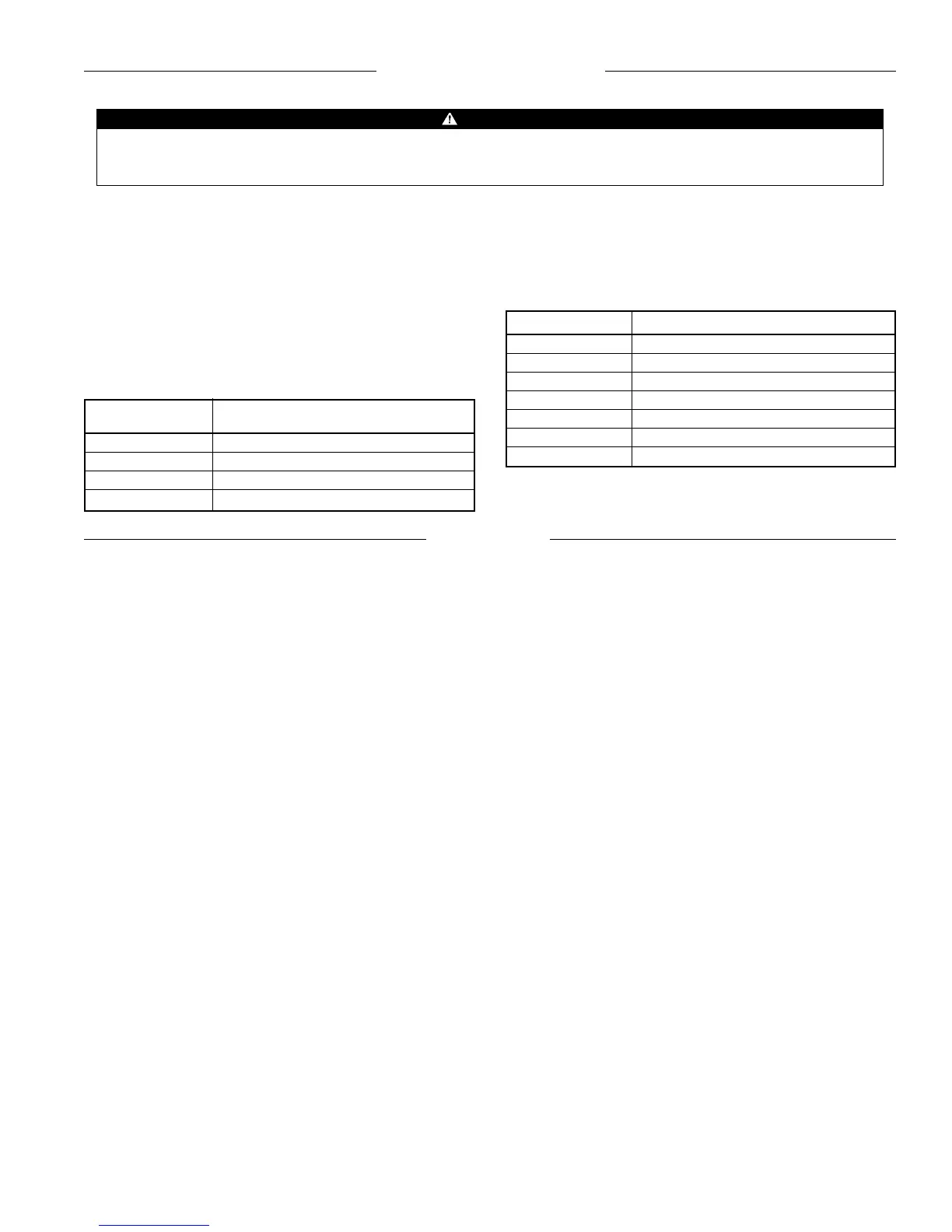

Model Data Bulletin Number

AE UV-3-204 (IM 502)

AZ UV-3-205 (IM 503)

AR UV-3-202 (IM 504)

AV/AH UV-3-200 (IM 506)

Table 5. Model-Specific Unit Ventilator Installation Literature

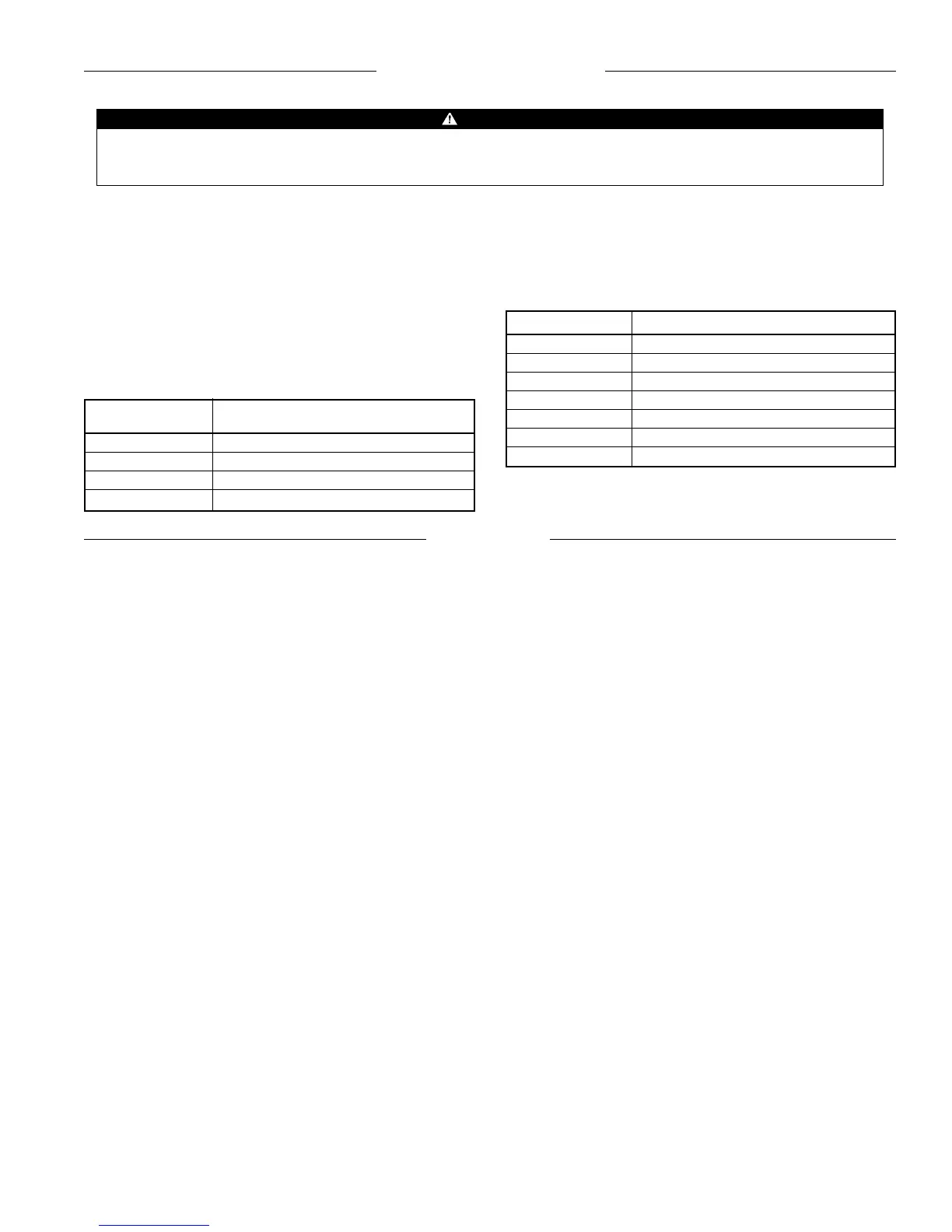

UVC Program Operation Manual Bulletin Number

UV1*** OM 101

UV2*** OM 102

UV3*** OM 103

UV4*** OM 104

UV5*** OM 105

UV6*** OM 106

UV7*** OM 107

Table 6. Program-Specific Sequence of Operation Literature

Pre-Start

Required Tools and Literature

The following tools and additional literature may be required to

properly commission a MicroTech UVC.

Tools:

1. Digital voltmeter

2. Digital ohmmeter

3. Digital thermometer

4. General technician’s tools

5. PC equipped with Monitor software (required for master/

slave and Network UVC, optional for stand-alone UVC’s)

Literature:

1. Model-specific unit ventilator installation bulletin (see Table

5)

2. Program-specific sequence of operation bulletin

(see Table 6)

Unit Ventilator Identification

The AAF-McQuay unit ventilators look similar; however, there are

significant internal differences which are defined by the model

number code string. In addition to the basic heating and cooling

equipment, the model number code string specifies which

factory-configured options have been provided. These options

determine the internal wiring configuration and the field

wiring requirements.

Obviously, it is extremely important that the correct unit

ventilator be placed in the correct location in accordance with job

requirements. Proper unit ventilator location should have been

determined during the installation process. Nevertheless, proper

location must be verified during the commissioning process.

Know Your Unit Ventilator

Before commissioning can proceed, the start-up technician must

know which options are supposed to be present on a particular

unit ventilator.

1. Check the model number code string against the job

requirements. Refer to the unit-specific installation bulletin

for a guide to model number nomenclature.

2. Check the program and software model numbers against

the unit model number code string. The UVC software must

be compatible with the unit ventilator configuration. Refer

to the “Software ID” section of this manual.

Note: If a PC is being used for commissioning, check the

software ID using the Monitor program. The controller’s

program is identified on one of the display screens.

Field Wiring Check

The unit ventilator factory-configured options determine the low

voltage field wiring requirements. If a specific option is present

on a particular unit ventilator (as denoted by the model number),

the associated field wiring (if any) must be checked.

Detailed electrical installation instructions and field wiring

diagrams are included in the model-specific installation literature

supplied with each unit ventilator. Referring to this literature and

using the following check lists, the start-up technician should

thoroughly check the electrical installation before the

commissioning process proceeds.

Wall Sensor Packages

1. Check that the cable is twisted and shielded.

2. Check that the required number of conductors are available.

3. Check that the shield is grounded in accordance with the

installation literature.

Loading...

Loading...