Certified Drawing

IM 613 / Page 7 (Rev. 7/99)

Compressor Short-Cycle Protection

All compressor-equipped unit ventilator models (self-contained

or split system) include compressor short-cycle protection.

When a compressor is energized, it will remain energized for at

least 2 minutes before the temperature control sequence will be

allowed to de-energize it. An alarm condition can override this

“minimum-on” timer and stop the compressor if necessary.

When a compressor is de-energized, it will remain

de-energized for at least 3 minutes before the temperature

control sequence will be allowed to energize it again.

Low Ambient Lockout

Except for the water source heat pump (WSHP) models, all

compressor-equipped unit ventilators (self-contained or split

system) include compressor low ambient lockout protection.

This feature will prevent compressor operation when the unit is in

the cooling mode and the outdoor air temperature is below 59°F.

Random Start

A random start feature is provided with all compressor-equipped

unit ventilators (self-contained or split system). This feature will

prevent simultaneous compressor start-up that could otherwise

occur after the following events:

• Unit power-up

• Unoccupied to occupied changeover

• Brownout condition

The compressor start delay can be from 1 to 63 seconds and is

determined by the UVC hex switch setting. For more information,

refer to “Hex Switches” in the “Component Data” section of this

manual.

Delayed Reversing Valve De-energization

All heat pump unit ventilator models have a 60-second (default)

reversing valve de-energization delay feature.

This delay prevents the reversing valve from returning to its

normal (cooling) position for a period of 60 seconds after the

compressor is de-energized when the unit is in the heating mode.

If necessary, an alarm condition can override the 60-second timer

and de-energize the reversing valve with the compressor.

Emergency Heat

All heat pump unit ventilator models that are equipped with

electric heat have an emergency heat feature.

The emergency heat mode is initiated by depressing the

momentary, unit-mounted emergency heat switch. When the unit

is in the emergency heat mode, the following actions occur:

• Compressor is immediately de-energized and locked out.

• Reversing valve is de-energized after a delay.

• Electric heat is staged to maintain the room heating

setpoint regardless of outdoor air temperature

(ASHP units) or entering water temperature (WSHP units).

The unit ventilator may be returned to normal operation by

cycling power to the controller (use fan switch or main

power switch).

ASHP Units Only: Note that the emergency heat switch (SW5)

and defrost control contacts are wired in parallel and use the

same UVC digital input (DI-3). The emergency heat switch

provides a momentary contact closure and the defrost control

provides a maintained contact closure. Therefore, do not hold

the emergency heat switch down or the unit may enter the

defrost mode instead of the desired emergency heat mode.

Defrost

The AE air source heat pump (ASHP) unit ventilator models have

a defrost cycle which prevents frost from building up on the

outdoor coil when the unit is operating in the heating mode.

An external defrost control provides a maintained contact

closure to the UVC when defrost is required.

When the unit is in the defrost mode, the following

actions occur:

• Reversing valve is de-energized (unit enters “cooling” cycle).

• Electric heat is staged to maintain the room setpoint

regardless of outdoor air temperature.

• Compressor cannot be de-energized by room temperature

control until defrost mode ends.

For further information on the defrost control cycle, refer to

Bulletin No. OM 101, MicroTech Unit Ventilator Controller

Sequences of Operation: Program UV1.

Alarm Monitoring & Controlled Response

The MicroTech UVC is capable of sophisticated alarm

monitoring and controlled response functions. Each alarm

(or “fault”) is prioritized, indicated, and responded to with the

appropriate action. If multiple alarms are present, the alarm with

the highest priority is indicated.

A summary of the available alarm features is shown in Table 3.

For more information, refer to the “Alarm Monitoring &

Control” section of this manual. Following are brief descriptions

of each feature.

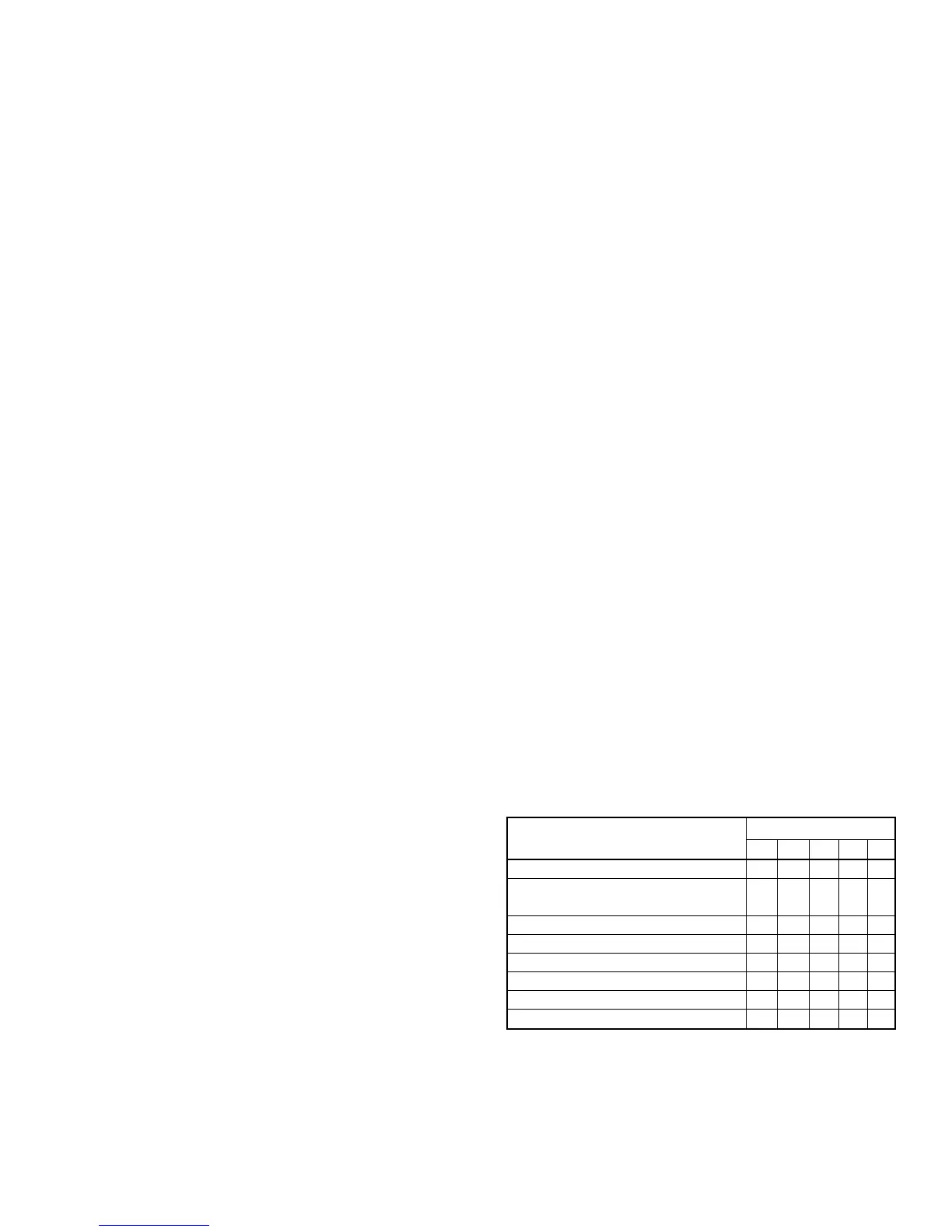

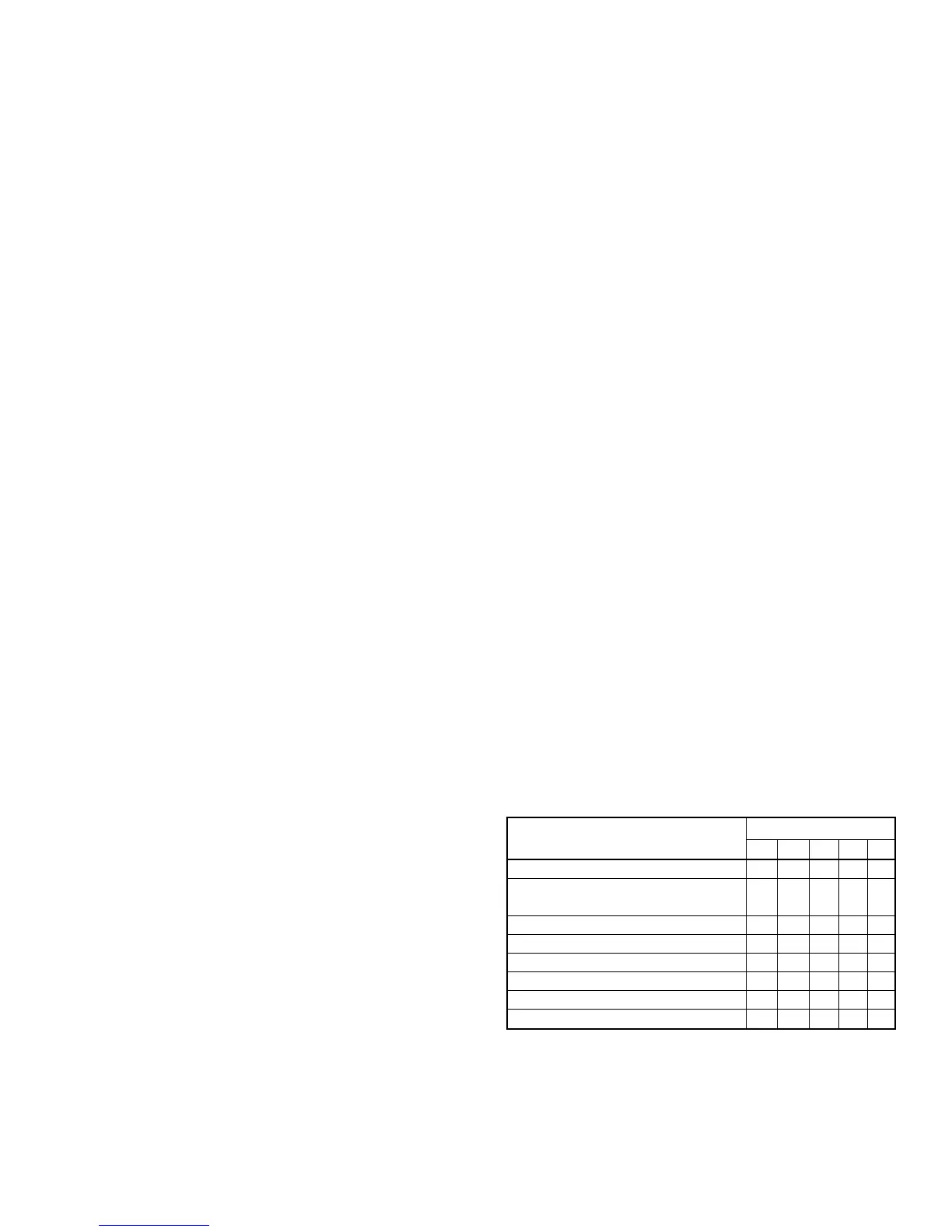

Alarm & Controlled Response Feature

Unit Ventilator Model

AE AZ AR AV AH

Sensor Diagnostics (Each Sensor) • • • • •

Actuator Feedback Diagnostics

•••••

(Each Actuator)

Brownout Protection • • • • •

High Pressure • • •

Low Coil Temperature (DX and/or Water) • • • • •

Low Refrigerant Temperature (Water Coil) •

Communication Error (Master/Slave Only) • • • • •

Change Filter (Network Units Only) • • • • •

Table 3. Alarm & Controlled Response Feature Availability

Loading...

Loading...