Certified Drawing

IM 613 / Page 5 (Rev. 7/99)

Status LED State Indication

On Continually Occupied Mode

On

1

⁄2 sec./ Off 5

1

⁄2 sec. Unoccupied Mode

On 5

1

⁄2 sec./ Off

1

⁄2 sec. Tenant Override Mode

Flashing* Alarm Condition

On 3 sec. / off 3 sec.** Calibration

on-board status LED. If used, the remote LED is connected to

the UVC at the terminal section labeled “LED.”

Power LED

The green, on-board power LED indicates microprocessor “on”

status. After applying power to the unit, the power LED should

illuminate continuously. For more information, refer to “Test

Procedures” in the “Service Information” section of this manual.

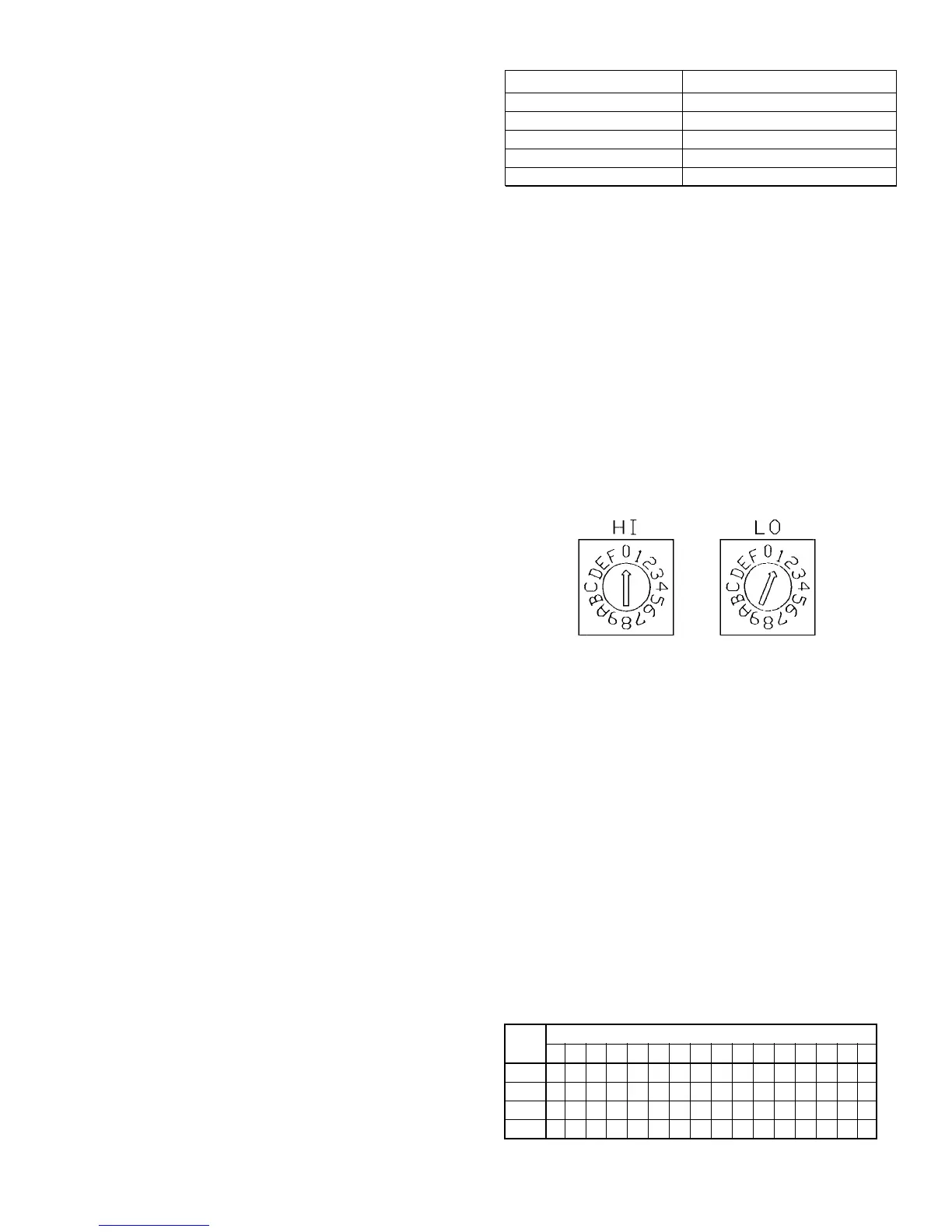

Hex Switches

The UVC includes two hex (hexadecimal) switches that may need

to be set. The HI and LO hex switches are shown in Figures 1

and 2. Table 2 provides a hex-to-decimal conversion guide.

A “hex switch setting” is defined as the HI switch digit followed by

the LO switch digit. For example, a hex switch setting of 2F would

have the HI switch set to “2” and the LO switch set to “F.”

Stand-alone Units

On compressor-equipped units (self-contained or split system),

the hex switch setting defines the random start delay period. Each

unit on a common circuit or time clock should have a different

hex switch setting to ensure that multiple units do not start

simultaneously. The settings may be between 01 and 3F.

If the unit ventilator has no compressor, leave the hex switch

setting at 01.

Master, Slave and Network Units

The hex switch setting defines the controller’s network address.

(If the master, slave or network unit has a compressor, the

random start delay is also defined by the hex switch setting.) For

more information on master/slave addressing, refer to “Master/

Slave” in the “Start-up” section of this manual. For more

information on MicroTech network addressing, refer to the

MicroTech Network Master Panel installation bulletin.

Microprocessor

The UVC contains a microprocessor that is preprogrammed with

the software required to monitor and control the unit. It receives

input data from as many as 20 inputs (analog or digital) and sends

commands to as many as 8 outputs (electromechanical relays).

(There are 2 additional solid-state relay “aux” outputs which are

not used for standard unit ventilator configurations.) The quantities

and types of inputs and outputs are dependent on the unit venti-

lator model type and configuration options. All input and output

connections to the UVC are made using insulation

displacement type (IDC) terminal connectors.

The UVC uses field-adjustable setpoints and fixed,

preprogrammed parameters to maintain unit control. (Many of

the preprogrammed parameters can be adjusted with a PC

equipped with Monitor software.)

Setpoint Adjustment Potentiometers

There are three setpoint adjustment potentiometers (pots) on

the UVC:

• Minimum outdoor air damper position pot

• Heating setpoint pot

• Unoccupied offset adjustment pot

Note: On slave and network controllers, these three setpoint

values are received via network communications, and the

pot settings are ignored. On slave controllers only, the

pot settings are used when communications are lost.

Therefore, it is recommended that appropriate “default”

pot settings be set for slave units.

Minimum Outdoor Air Damper Position Pot

The minimum position pot defines the minimum outdoor air (OA)

damper position. The OA damper is typically held at its minimum

position when cooling is not required or when the OA temperature

is not suitable for free cooling. Refer to the sequence of operation

document provided with your unit for more detailed

information.

Heating Setpoint Pot

The heating setpoint pot adjusts both the occupied cooling and

heating setpoints. The room occupied heating setpoint is shown

on the UVC faceplate. The room occupied cooling setpoint is

calculated by adding the deadband value to the heating setpoint

(deadband default = 6°F).

Unoccupied Offset Adjustment Pot

The unoccupied offset pot sets the offset value used to deter-

mine the unoccupied heating (or night setback) and unoccupied

cooling (or night setup) setpoints. The night setback setpoint is

calculated by subtracting the offset value from the occupied

heating setpoint. The night setup setpoint is calculated by adding

the offset value to the occupied cooling setpoint.

Status LED

An amber, on-board status LED aids in diagnostics by indicating

the unit ventilator operating mode and alarm conditions. If there are

no current alarm conditions, the LED will indicate the unit operating

mode as shown in Table 1. If there are one or more alarm condi-

tions present, the LED will flash in a specific sequence to indi-

cate a particular alarm condition. For more information on alarms,

refer to the “Alarm Monitoring & Control” section of this manual.

A remote status LED is provided with all optional wall- mounted

temperature sensor packages. It has the same function as the

Figure 2. Hex Switches

Table 1. Status LED Indication

* Refer to Table 9 in the “Alarm Monitoring & Control” section of this manual.

** Calibration of OA Damper, F&BP Damper, and/or valve actuators will be

completed within approximately 5-min after power-on.

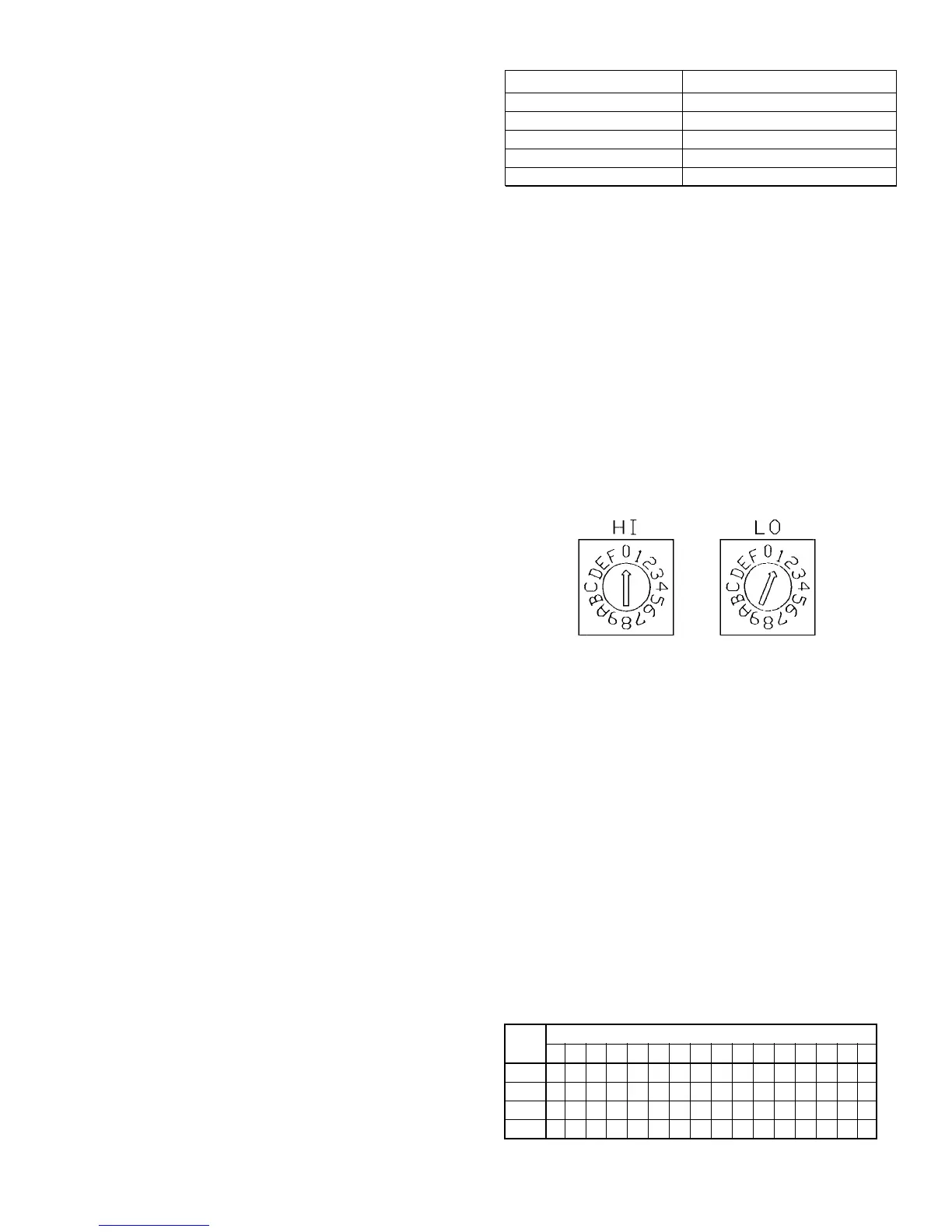

HI Hex

LO Hex Digit

Digit 0123456789ABCDEF

0 0*123456789101112131415

1 16171819202122232425262728293031

2 32333435363738394041424344454647

3 48495051525354555657585960616263

Table 2. Hexadecimal to Decimal Conversion Guide

* Hex switch setting 00 has a special purpose. It should not be used for

normal operation.

Loading...

Loading...