IM 613 / Page 12 (Rev. 7/99)

4. Check that the conductors have been terminated at the unit

and the wall sensor package in accordance with the field

wiring diagram.

5. Check that the cable length between the wall sensor package

and its UVC does not exceed 250 feet.

6. 460V, Type AE & AZ Only: Check that 600-volt rated cable

has been used.

Network Communication (Master/Slave or MicroTech

Network Units)

1. Check that the cable is a twisted, shielded pair of

conductors.

2. Check that the shield is grounded in accordance with the

installation literature.

3. Check that the conductors have been terminated at the units

in accordance with the field wiring diagram.

4. At the UVC board, verify that the IDC connectors are

disconnected from the Comm A and Comm B ports.

(They will be connected during the start-up process.)

5. 460V, Type AE & AZ Only: Check that 600-volt rated cable

has been used.

6. MicroTech Network Units Only: Check that the conduc-

tors have been terminated at the Local Master Controller

(LMC) in accordance with the field wiring diagram supplied

with the LMC. Check that the cable length between the LMC

and the farthest UVC does not exceed 5000 feet.

Day-Night Changeover (Stand-alone or Master Units)

1. Check that the conductors have been terminated at the unit

in accordance with the field wiring diagram.

Note: Field terminations are not required for the factory-mounted

time clock and manual switch options.

2. Check that the ultimate changeover device provides the

proper action at the UVC. The dry contacts connected to

DI-2 must be “open for occupied” and “closed for

unoccupied.” If used, the factory-installed relay is wired so

that it must be “de-energized for occupied” and “energized

for unoccupied.”

3. 460V, Type AE & AZ Only: Check that 600-volt rated

conductors have been used.

Ventilation Lockout (Stand-alone, Master or Slave Units)

1. Check that the conductors have been terminated at the unit

in accordance with the field wiring diagram.

2. Check that the field-supplied device energizes the factory-

installed relay when ventilation lockout is desired.

3. 460V, Type AE & AZ Only: Check that 600-volt rated

conductors have been used.

Exhaust Fan Interlock

1. Check that the conductors have been terminated at the unit

in accordance with the field wiring diagram.

2. Check that the field-supplied device energizes the factory-

installed relay when exhaust fan interlock is desired.

3. 460V, Type AE & AZ Only: Check that 600-volt rated

conductors have been used.

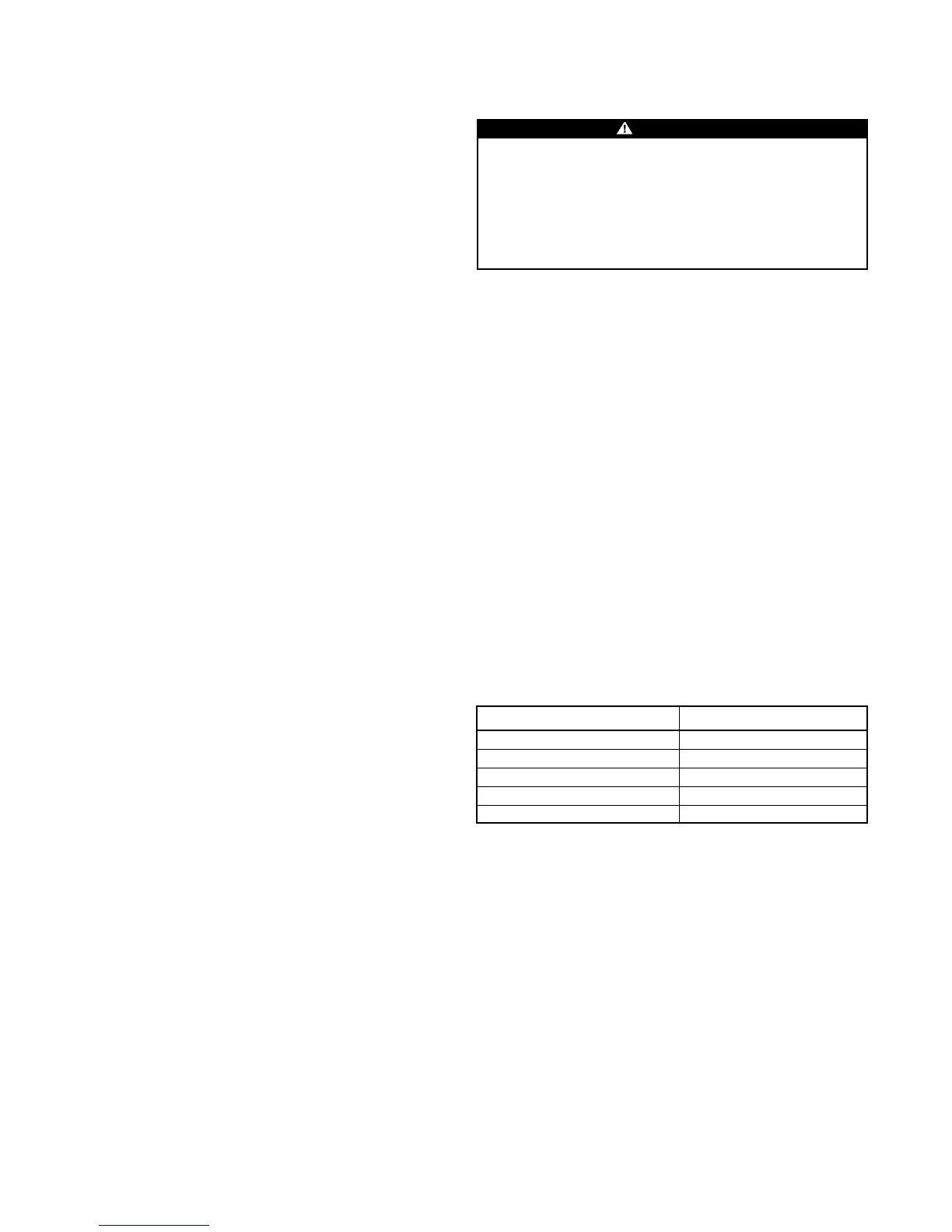

Setpoint Value

Occupied Cooling 78°F

Occupied Heating 72°F

Unoccupied Cooling 88°F

Unoccupied Heating 62°F

Minimum OA Damper Position 20%

Table 7. Network UVC Default Setpoints

Remote Condensing or Heat Pump Unit (AV/AH Units Only)

Check that the conductors have been terminated at the unit in

accordance with the field wiring diagram.

Setpoint Initialization

Stand-alone and Master/Slave Units

The heating setpoint, unoccupied offset, and minimum OA damper

position potentiometers (pots) should be set to the desired

settings prior to start-up. For more information, refer to “Setpoint

Adjustment Potentiometers” in the “Component Data” section of

this manual.

Note: In a master/slave application, the master’s pot

settings define the setpoint values for its slave controllers.

If communications fail, the affected slaves read their

setpoint values from their own setpoint pots. For this

reason, it is recommended that the three on-board setpoint

pots on each slave be set so that they match the master’s

settings.

Network Units

The three setpoint adjustment potentiometers on a network unit

are not operational. The UVC setpoint values are held in memory

and can only be modified over the MicroTech network. Initially,

before any changes are made over the network, the UVC will use

the default, factory-set setpoints shown in Table 7.

CAUTION

On AH units, it is recommended that the outdoor air

temperature sensor be located so that it will accurately sense

the outdoor air temperature. If this is not done, improper unit

operation or damage to the remote condensing or heat pump

unit could occur. The best location for the sensor is either

outside the building (shielded from solar radiation) or in the

outdoor air ductwork very near the intake.

Loading...

Loading...