IM 613 / Page 28 (Rev. 7/99)

UVC Replacement

Data relating to the unit ventilator configuration and actuator

characteristics are stored at the factory when each unit is built

and tested. This information defines the program number,

software model, and several parameter settings that are

unique for each unit ventilator. If a UVC is defective and must

be replaced, its unit-specific software (defined by the above

data) must be loaded into the replacement controller.

If a PC is available, it may be possible to recover the software

from the defective UVC.

If a PC is not available or the software cannot be recovered,

the replacement UVC must be downloaded at the factory. To do

this, the factory needs the following information:

• Full model number

• Serial number

• Job control number

This information is listed on the unit mounted dataplate. It must

be included with the replacement UVC part order.

Note: If the linkage is disconnected or damaged, it is

possible that the actuator could extend beyond the nomi-

nal full stroke of one-half inch. If it does, the feedback

voltage could exceed the acceptable upper limit.

5. Remove the IDC connector from the analog input and

measure the DC voltage across the UVC terminals. It

should be approximately 5 VDC. If it is, the actuator is

defective. If it is not, the UVC is defective.

Note: Stroke endpoint parameters for each actuator are loaded

into the UVC at the factory and auto calibrated at each

power-up. If an actuator must be replaced, the stroke

endpoint parameters in the controller may need to be

reset. If nuisance alarms are occurring or if a valve or

damper will not fully close, obtain factory service.

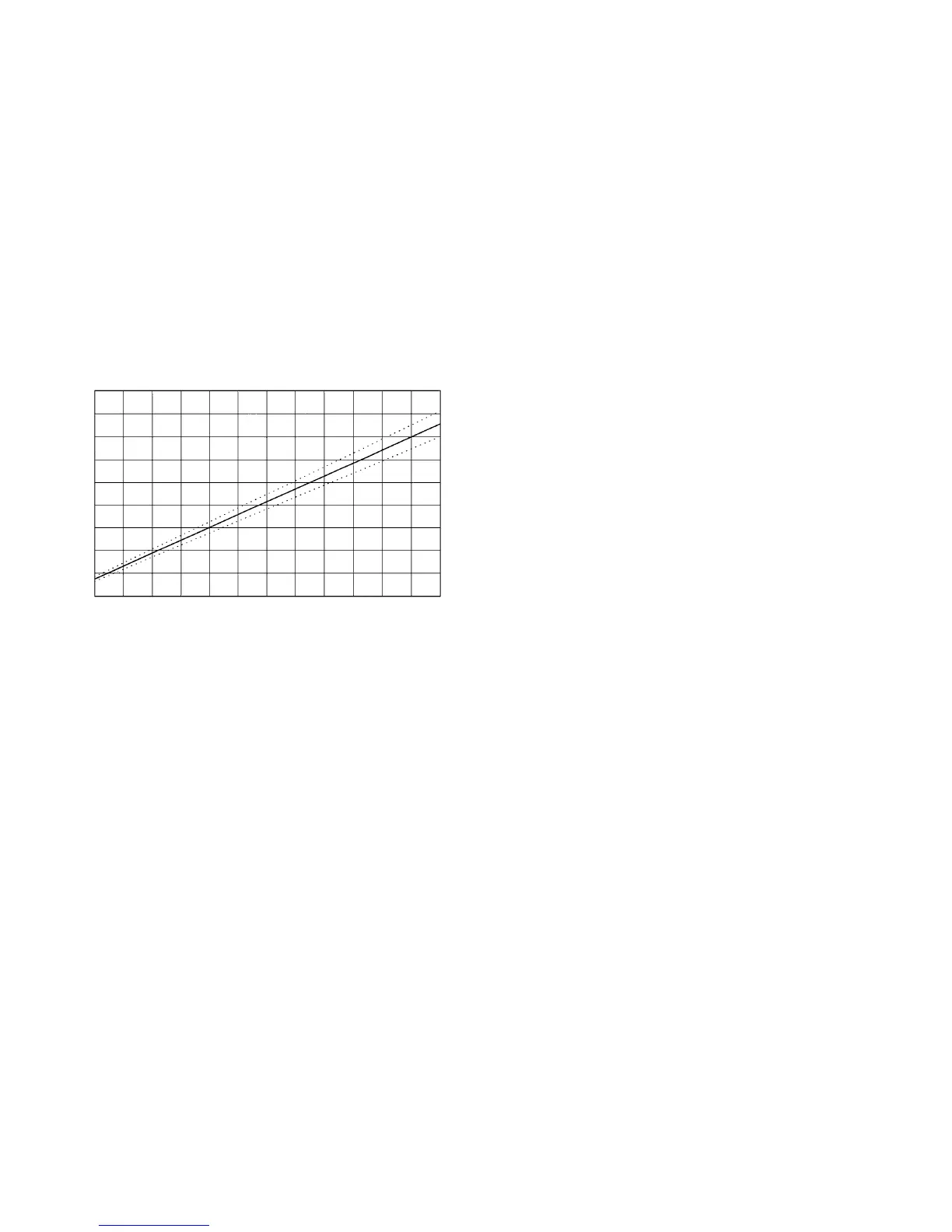

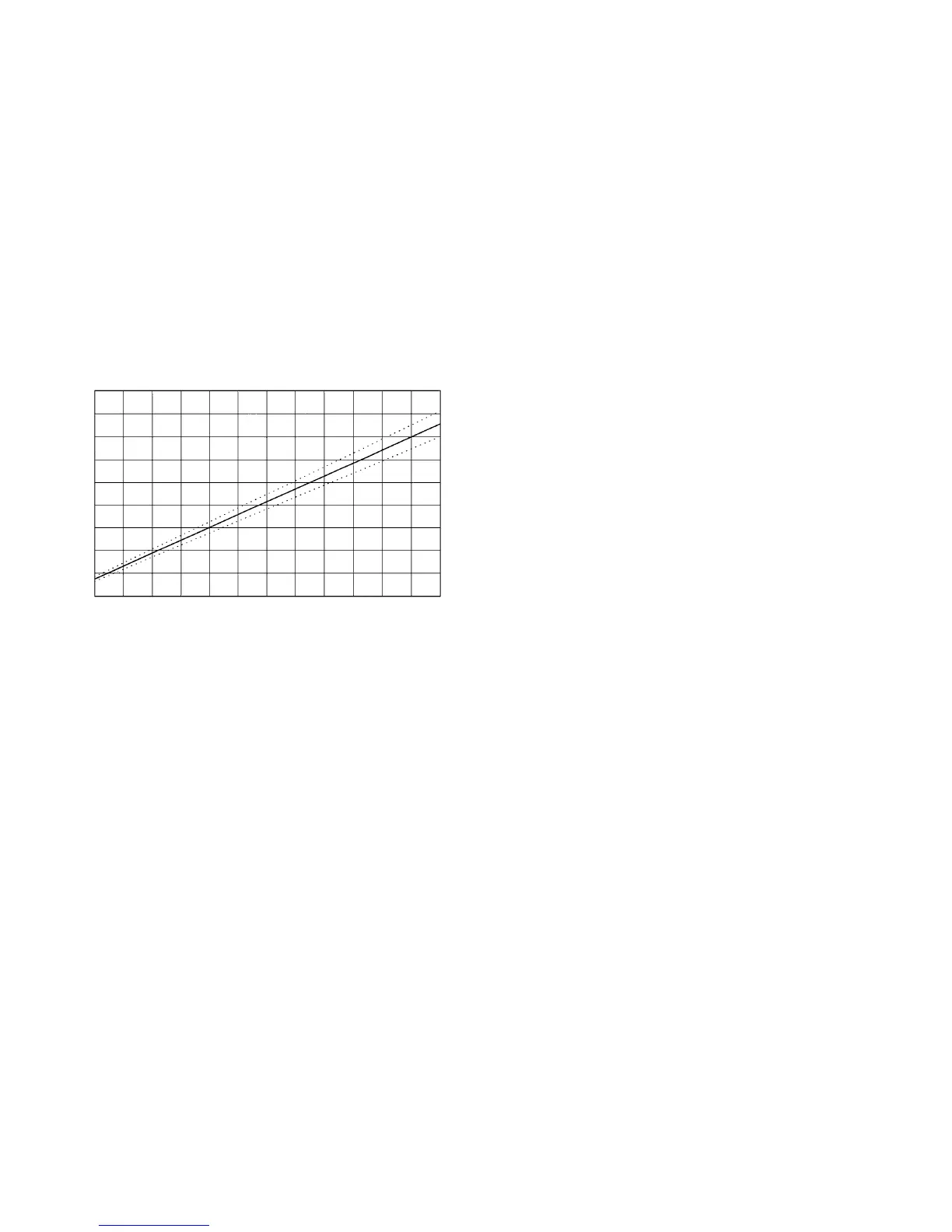

Figure 6. Barber-Colman Actuator Position Feedback Voltages

Notes:

1. Extension percentage is based on

1

/2-inch nominal full

stroke.

2. Voltages are measured at UVC analog input terminals.

3. Range of expected accuracy is defined by the dotted lines.

4. Voltage at maximum possible actuator extension is 4.63

VDC (linkage disconnected).

Master/Slave Communication Error Fault

A master/slave communication error is indicated by a 16-blink

fault code. Troubleshooting this fault is limited to the following

checks:

• Verification of master and slave UVC communication port

voltages

• Verification of communications wiring integrity

• Verification of network addressing

The best way to accomplish these checks is to perform the

master/slave start-up procedure. Refer to “Master/Slave” in the

“Start-up” section of this manual.

If all of the above checks have been performed and the UVC

will still not communicate, either the controller is defective or

factory service is required.

0.0 0.4 0.8 1.2 1.6 2.0 2.4 2.8 3.2 3.6 4.0 4.4 4.8

160

140

120

100

80

60

40

20

0

-20

Actuator Extension (%)

Voltage (VDC)

Loading...

Loading...