Certified Drawing

IM 613 / Page 13 (Rev. 7/99)

Following are UVC start-up procedures for each communication

type. The start-up procedure must be performed by a qualified

technician for every UVC on a job.

Stand-alone

Because stand-alone controllers are independent of each other,

they may be started in any order.

PC Access

A PC is not required for stand-alone UVC start-up; however, the

start-up process will be easier and faster if a PC is used. If a PC

is used, it must be equipped with Monitor software. For further

information, refer to “PC Connection” in the “Service Information”

section of this manual.

Procedure for Each Stand-alone UVC

1. Verify that the main power switch is at “Off.”

2. Verify that the hex switch setting is not “00” or “FF.”

These settings are reserved for special applications. For

further information, refer to “Hex Switches” in the

“Component Data” section of this manual.

3. Compressorized Units Only (Self-contained or Split

System): Set hex switches for random start delay.

Valid settings are between 01 and 3F. For further

information, refer to “Random Start” in the “Standard

Control Features” section of this manual.

4. Apply power to the unit.

Turn the main power switch to “On” and the motor speed

switch to the desired speed, wait 5-minutes until calibration

is complete.

5. Check the status LED and operating mode changeover

devices. The status LED should illuminate after calibration.

If a wall sensor package is used, the remote status LED

should also illuminate. Referring to Table 1, verify that the

day-night changeover and tenant override options (if

present) are working properly. Do this by switching these

devices and observing the status LED.

6. Verify that the unit ventilator is operating in accordance with

its sequence of operation as outlined in the appropriate

documentation (refer to Table 6).

Since the sensed temperatures are fixed at any given

moment, adjust the room setpoint and unoccupied offset

pots to obtain the expected heating or cooling control

actions. If a PC is available, adjust any other applicable

parameters to obtain the expected UVC control actions.

7. Check the remote setpoint adjustment pot operation

(if present).

Verify that the expected UVC control action occurs when

the remote pot is adjusted up or down.

8. Check that the ventilation lockout option works properly

(if present).

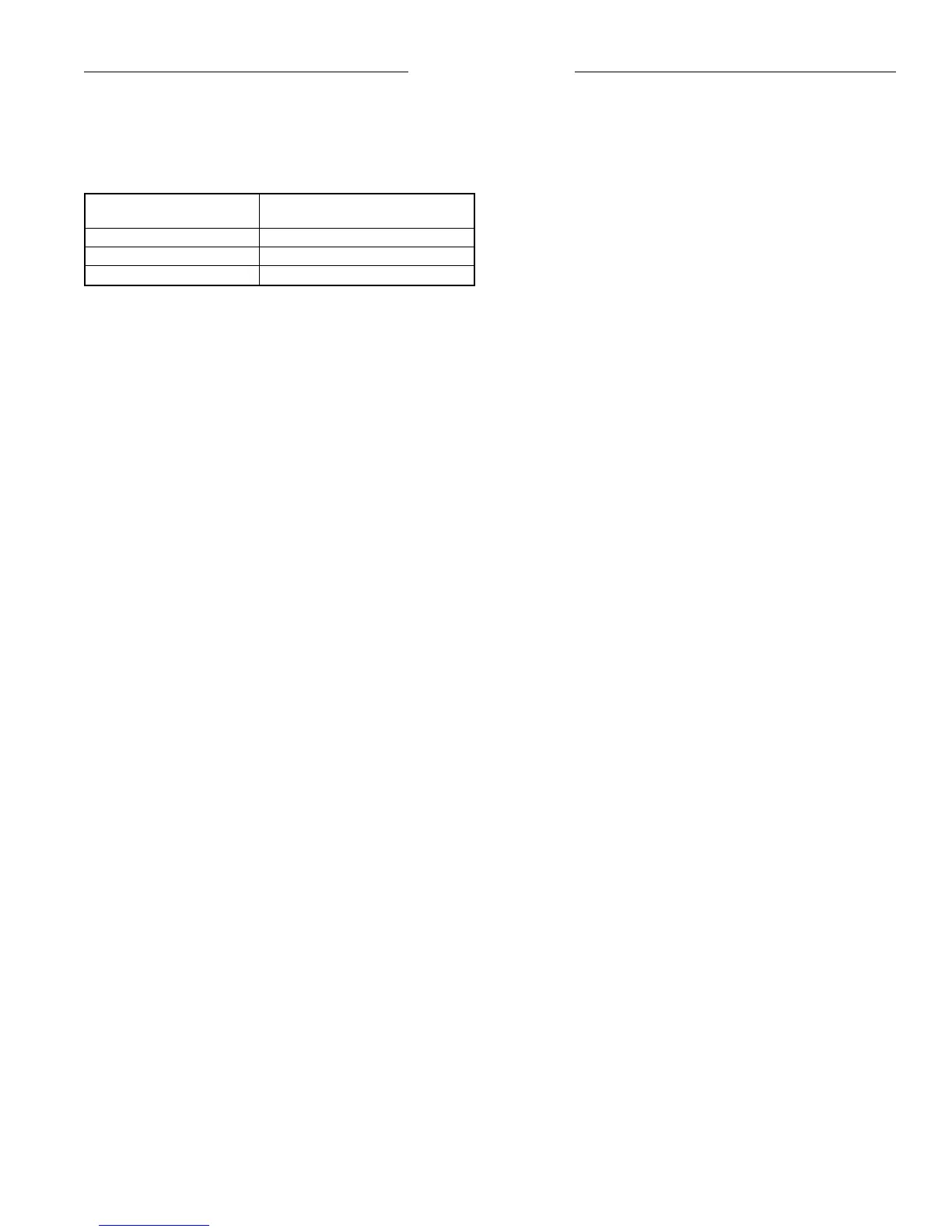

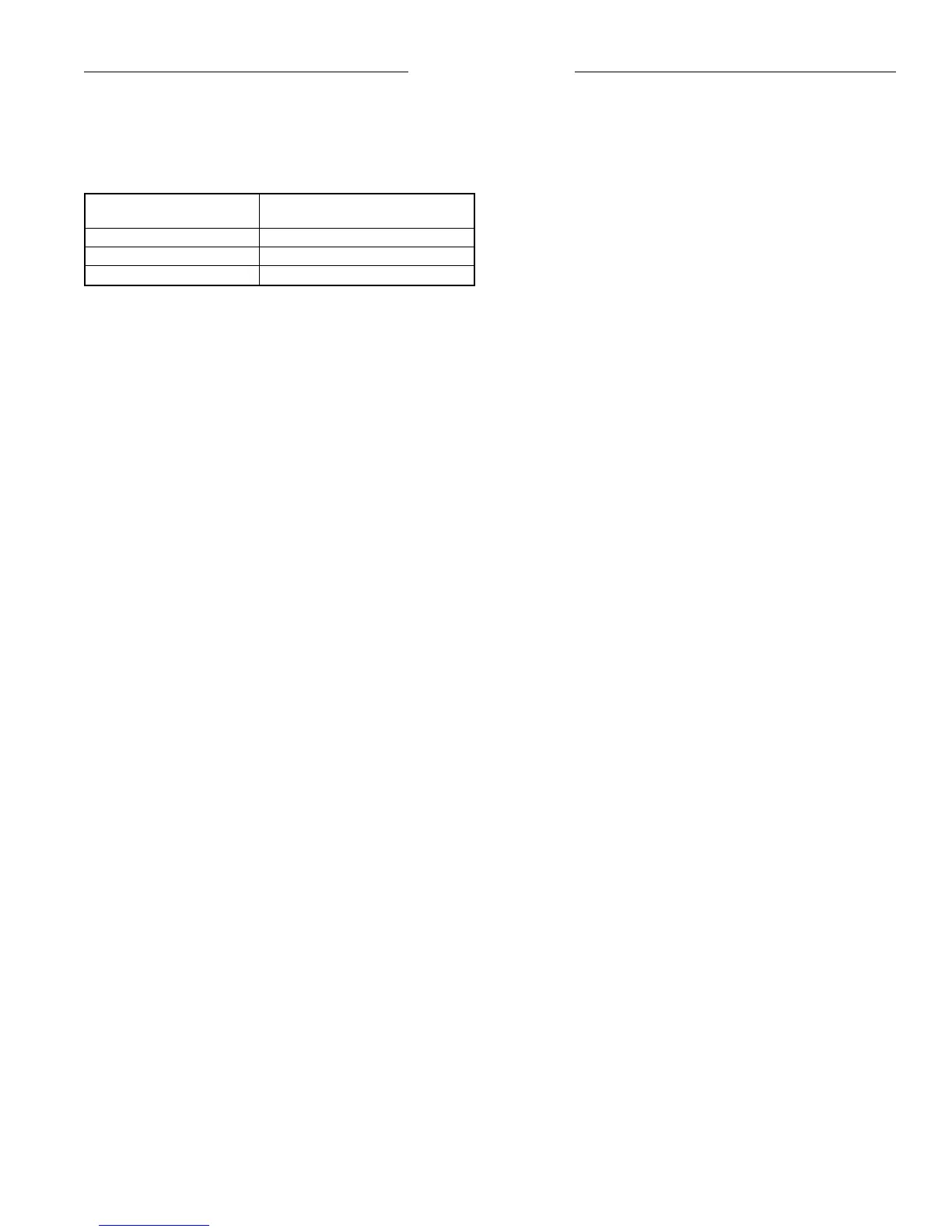

Communication Acceptable

Port Terminal Voltage Reading

4 (+) 3.0 ± 0.3 VDC

5 (-) 2.0 ± 0.3 VDC

6 (ground) 0.0 ± 0.2 VDC

Table 8. Network Communication Port Terminal Voltage Ranges

Start-Up

When the unit is in the occupied operating mode, verify

that the OA damper closes when the ventilation lockout

relay is energized.

9. Check that the exhaust fan interlock option works properly

(if present).

Verify that the OA damper opens when the exhaust fan

interlock relay is energized.

Master/Slave

Because it provides operating mode and setpoint information to

the slaves on its network, the master UVC must be started

before any slave. After the master has been started, the slaves

may be started in any order. However, if the start-up order follows

the daisy chain from the master UVC to successive slaves, it will

be easier to detect any wiring problems that may exist in the

communications trunk.

To perform the setup procedures on the next page you must have

the Windows Monitor program installed on a PC, the PC must be

connected with proper cabling to Port-A on the MicroTech con-

troller, and you must have established communication between

the PC and the controller. The cable kit required to properly

connect a 9-pin serial PC port to Port-A on a MicroTech controller

is P/N 057186802 which will contain cables P/N 067784501 and

P/N 067784503.

The DOS Monitor program may also be used to perform these

setup procedures.

Points to keep in mind about Master/Slave Units

• Master/Slave controllers must be either all MicroTech 125

or all MicroTech 325; you cannot mix 125’s with 325’s and

vice versa.

• Master/Slave networks that have both new and old EOS

version MicroTech 325 controllers must use a new EOS

controller for the Master (new EOS 325 controllers are

labeled 21.169 or 21.A9, all other 325’s are old EOS).

• Master/Slave controllers both use the same program

(UV*M**.COD).

• All units are shipped as stand-alone units. Master/Slave

code must be downloaded and then Master/Slave configu-

ration performed.

• Slave UVC’s are considered to be independent slaves, this

means that Slave UVC’s obtain their setpoints from the Mas-

ter UVC but the Slave UVC’s then operate based upon their

own sensors.

• Port-A on a Master UVC unit will not communicate as you

may expect a stand-alone UVC to communicate. If you must

connect directly with a Master UVC, you must first set its

HEX network address switches to FF then cycle power. The

address to use in the Monitor program would then be 00.FF.

While the HEX network address switches are set at FF, the

Master UVC will not communicate with the Slave UVC’s

properly; therefore, you must remember to return the HEX

switches to their proper settings, then cycle power when

you are done.

Loading...

Loading...