Flooded type water cooled screw chiller (PCB Control) MCAC-CTSM-2012-11

60

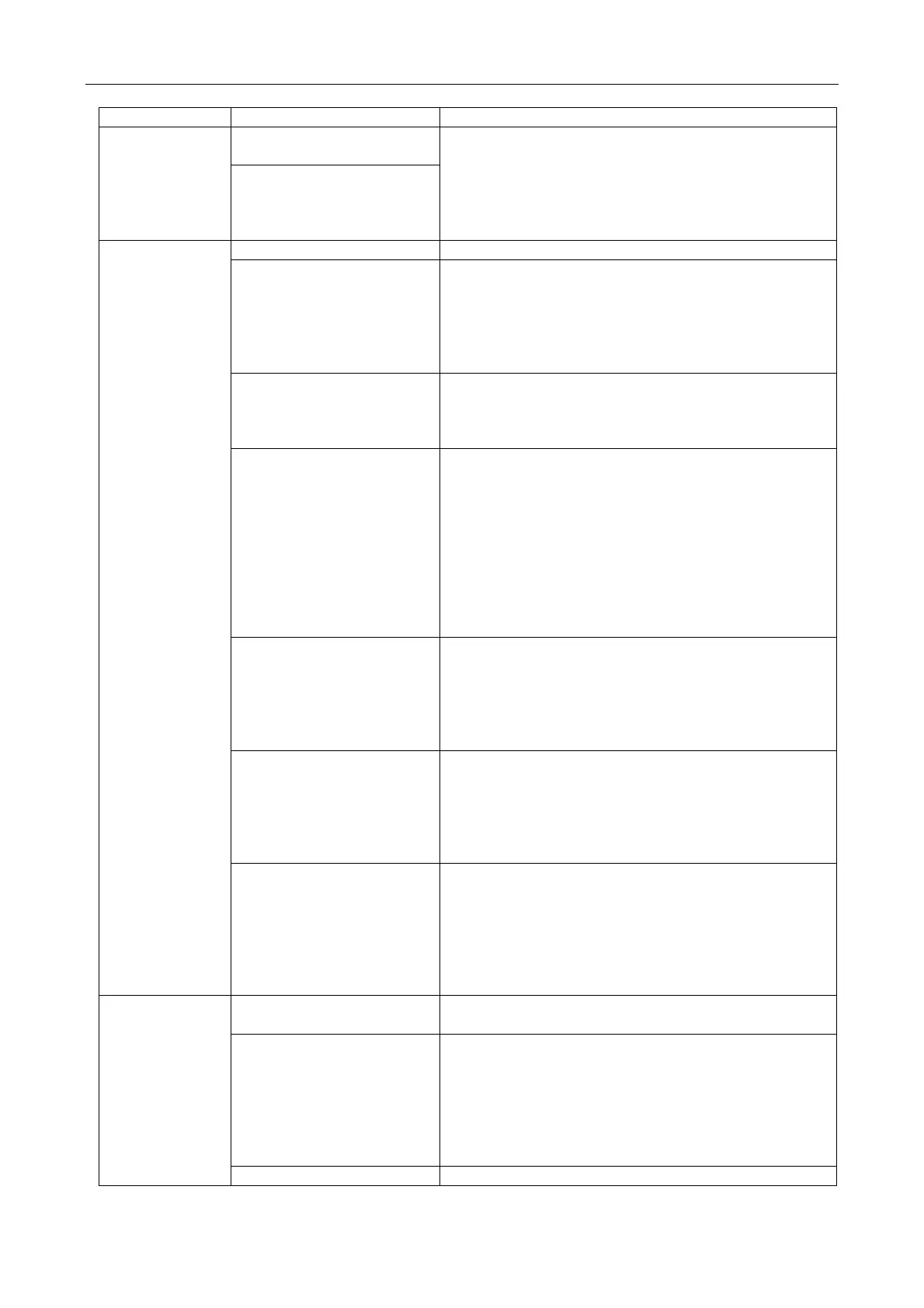

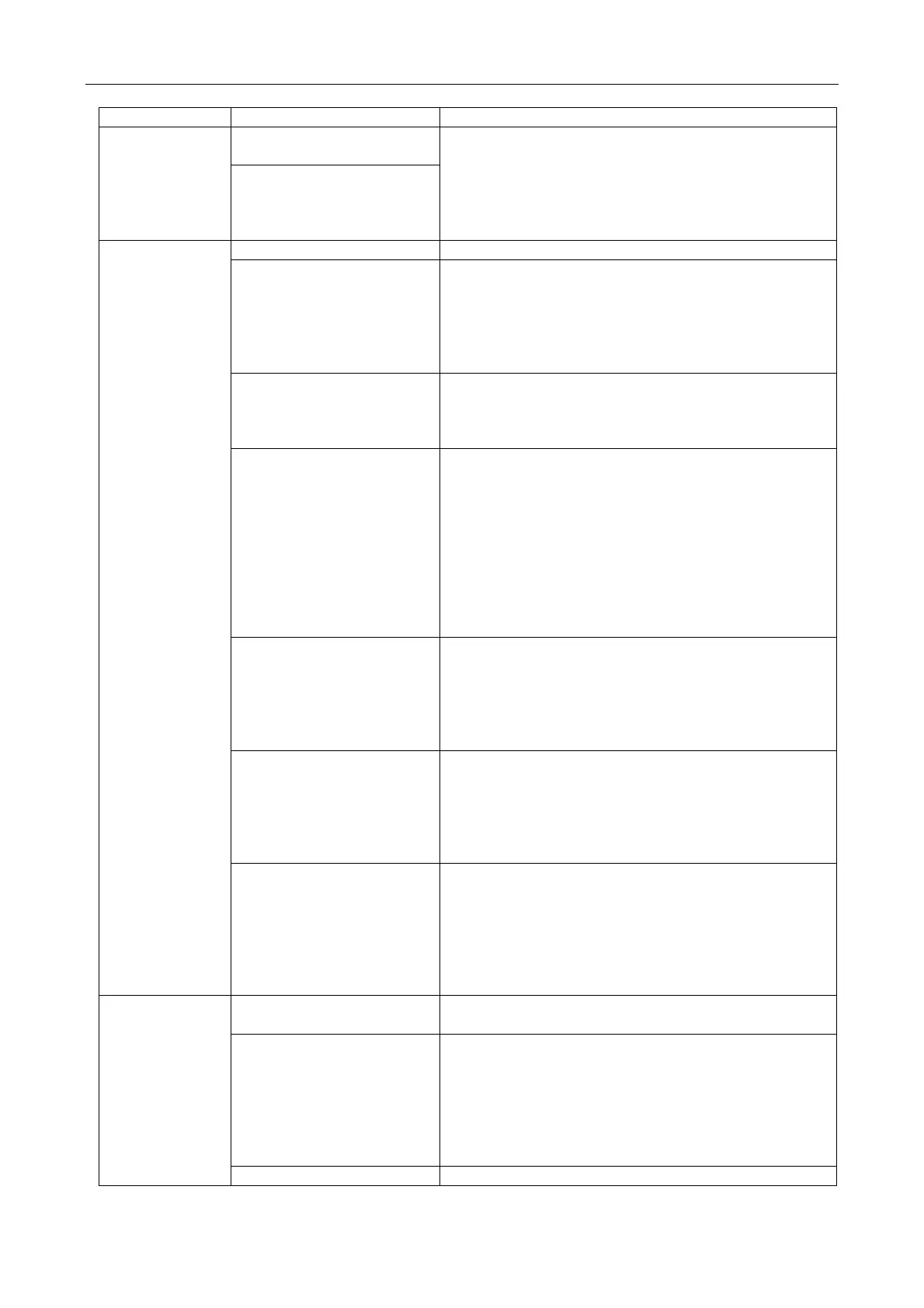

EXV Troubleshooting:

Problem Reason Solution

Measured

superheat

value is

incorrect

Measured superheat

value is incorrect

Check that the measured pressure and temperature

sensors correctly and the correct position.

Check on the drive set minimum and maximum

pressure pressure sensor parameter with the range

of pressure sensors installed in line.

Check sensor electrical wiring is correct.

Set the wrong type of

refrigerant

liquid back to

the compressor

during the

control

Valve type setting error Check and correct valve type parameters

Valve connection error

(rotation in the opposite

direction) and is open

And manual control valve is completely closed or

open, to check the valve rotation. A fully open valve

Superheat can be decreased, and vice versa so

that the superheat values have increased. If the

valve is rotating in the opposite direction, check

electrical wiring.

Superheat setting is too

low

Check superheat setting. Beginning to set 12 ° C,

check to make sure there is no return of liquid. Then

gradually reduce the set value, but always returning

to ensure that no liquid.

Low superheat protection

is invalid

If low superheat value of long duration and the valve

closes slowly, then increase the degree of protection

of low superheat threshold and / or protection to

lower superheat integration time. The beginning of

the threshold value is set lower than the superheat

setting 3 ° C, points time is set to 3-4 seconds. Low

heat and then gradually reduce the threshold and

increase the integration time, check to make sure the

under any operating conditions there was no return

of liquid.

Valves damaged or

connected incorrectly the

stator

The stator and the valve and disconnect the cable

connection, with ordinary measuring coil resistance

tester.

Two coil resistance should be around 36 Euro.

Otherwise, replace the stator. Finally, check the

connection of electric drive cable wiring.

Valve can not close Always check the superheat value is too low (<2 ° C)

and the valve position is always 0 step. If the above

situation, the valve is set to manual control and

completely shut down. If the superheat value is

always low, check the electrical wiring and / or

replacement the valve.

Often to control the

settings in the refrigerated

cabinet set "Start at the

valve opening degree

control" parameter too

High (only for composite

refrigerated cabinet)

In all uses are reduced" began to control the valve

opening degree" parameter values, make sure to

control the temperature will not be affected

Liquid only

during the

defrosting

returned to the

compressor

( only

applicable to

composite

refrigerating

cabinet )

Defrosting control after the

pause time is too short

Increasing the " defrosting valve control delay"

parameter values

Defrosting and reaches

operating conditions

before drive the measured

degree of superheat

temperature is very low,

and continued for a few

minutes

Check and confirm the LowSH threshold is higher

than the measured value of the superheat, and

activate the corresponding protection function

( integration time > 0 seconds ). When necessary,

reduced integration time

Drive the measured Setting a more sensitive parameter, so that the valve

Loading...

Loading...